Automatic powder weighing machine for CBN cutter and powder weighing method thereof

A powder weighing and automatic technology, applied in automatic feeding/discharging weighing equipment, weighing equipment with special properties/forms, weighing and other directions, can solve problems such as low powder weighing efficiency and achieve weighing. Take the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

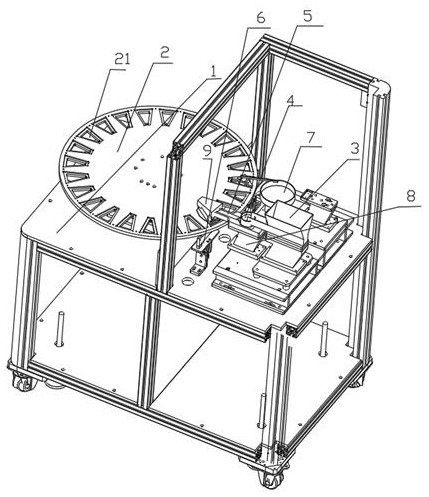

[0023] The invention discloses an automatic powder weighing machine for CBN cutters, combining figure 1 As shown, it includes an operating platform 1, on which a rotating mechanism is provided, and the rotating mechanism includes a rotating platform 2 and a driving motor (not shown in the figure) placed under the rotating platform. The cross-section of the rotating platform 2 is circular, and powder receiving grooves 21 are evenly distributed on the rotating platform, and the powder receiving grooves are distributed along the circumference of the rotating platform 2 . A powder receiving box matching the powder receiving tank 21 is arranged in the powder receiving tank.

[0024] A weighing mechanism 6 for weighing the amount of powder in the docking powder box is also arranged under the rotating platform 2, and the weighing mechanism 6 is in contact with the bottom of the powder receiving box. One side of the rotating mechanism is provided with an unloading mechanism. The bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com