Automatic static metering system and automatic control method for continuous unloading of wharf materials

A static measurement and material technology, which is applied in the field of continuous automatic measurement of metallurgy, mines, and wharf materials. It can solve the problems of high transshipment costs, large quantities, and the inability to guarantee the accuracy of measurement data, and achieve the effect of improving weighing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

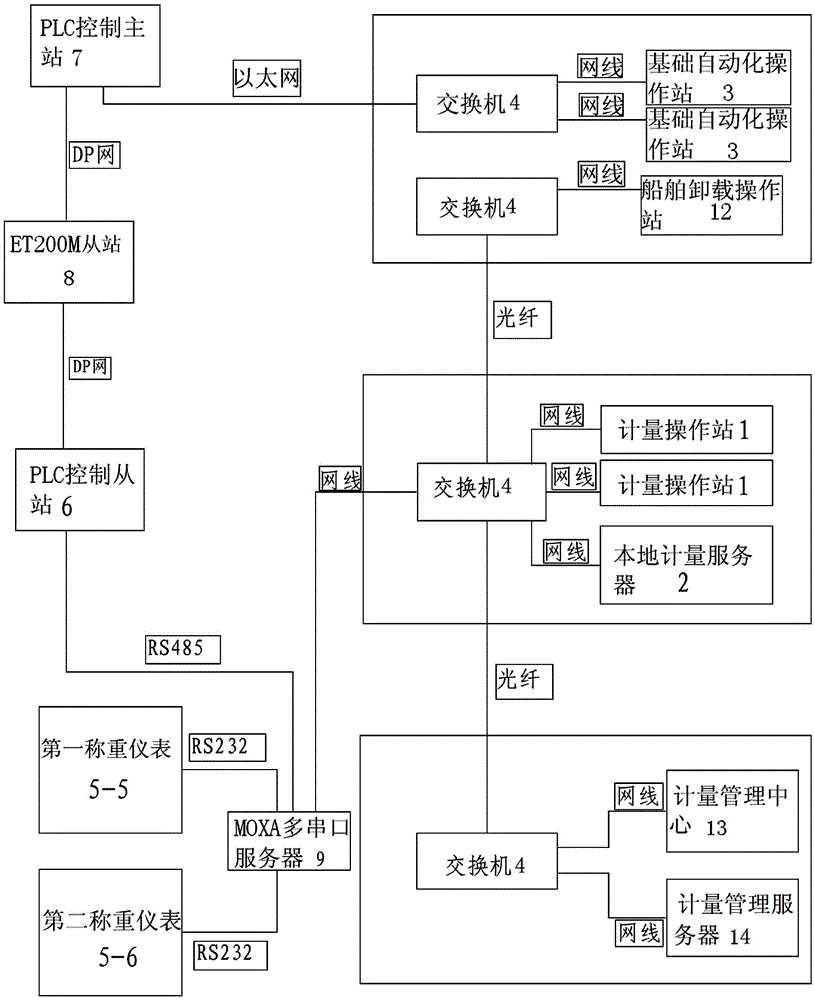

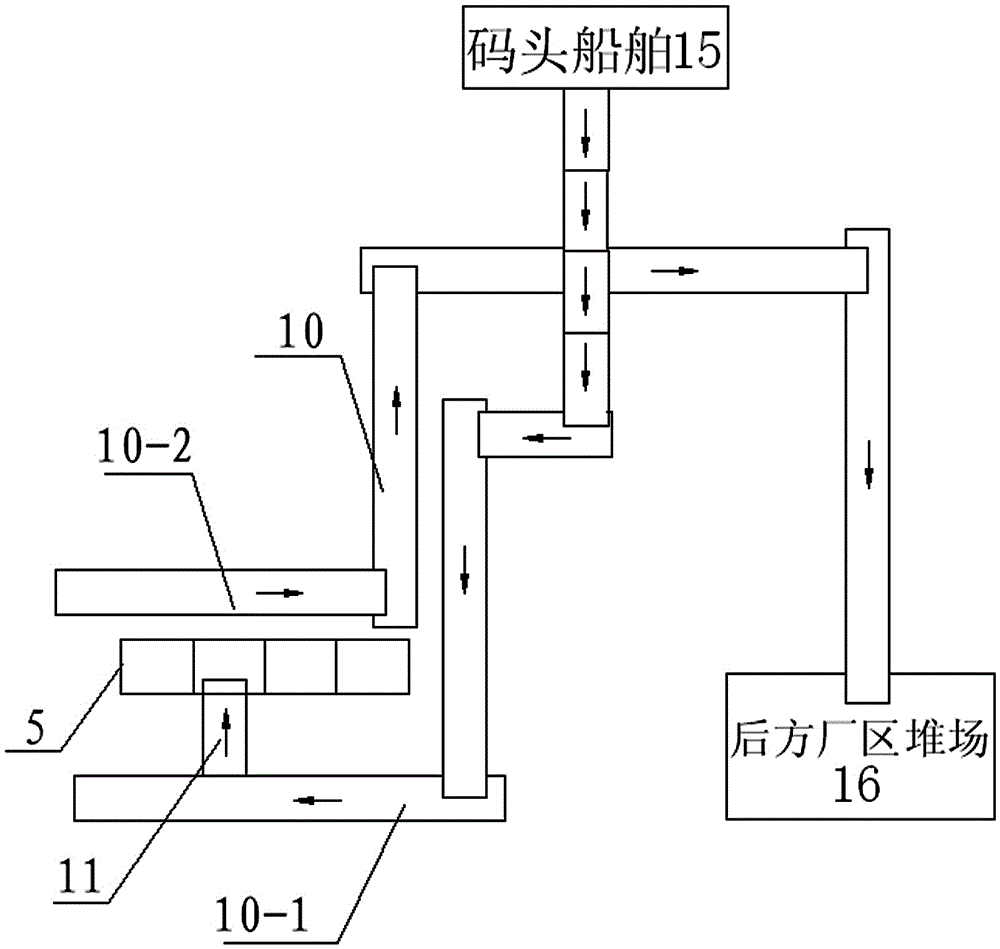

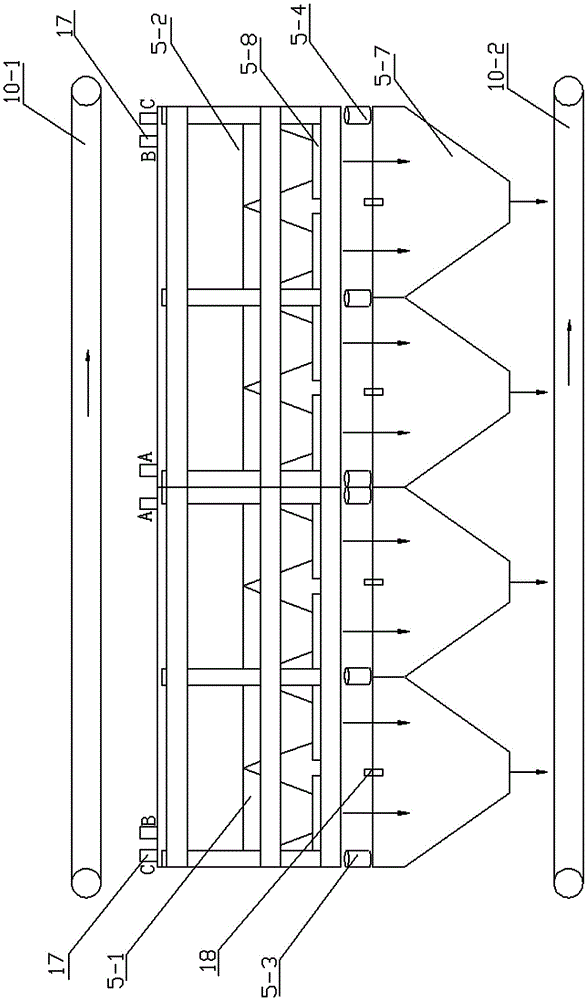

[0034] see Figure 1 to Figure 6 As shown, an automatic static metering system for continuous unloading of dock materials, including a metering operation station 1, a local metering server 2, a basic automatic operation station 3, a switch 4, a material weighing device 5, a MOXA multi-serial port server 9, and a material conveying device 10 , the distributor 11 of the material conveying device 10, the communication cable and the PLC controller, the material conveying device 10 adopts a belt conveying device, the material conveying device is controlled by a PLC controller, and the belt conveying device is divided into two sections, the first section of the belt conveying device One end of 10-1 is located at the wharf ship 15, and the other end is connected with a distributor 11 for distributing. The second section of belt conveyor 10-2 extends to the rear factory yard 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com