Rapid sampling device for food detection

A sampling device, food detection technology, applied in the sampling device and other directions, can solve the problems of sample pollution, affecting the efficiency of detection, and cumbersome sampling, and achieve the effect of avoiding pollution and automatic and rapid sampling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

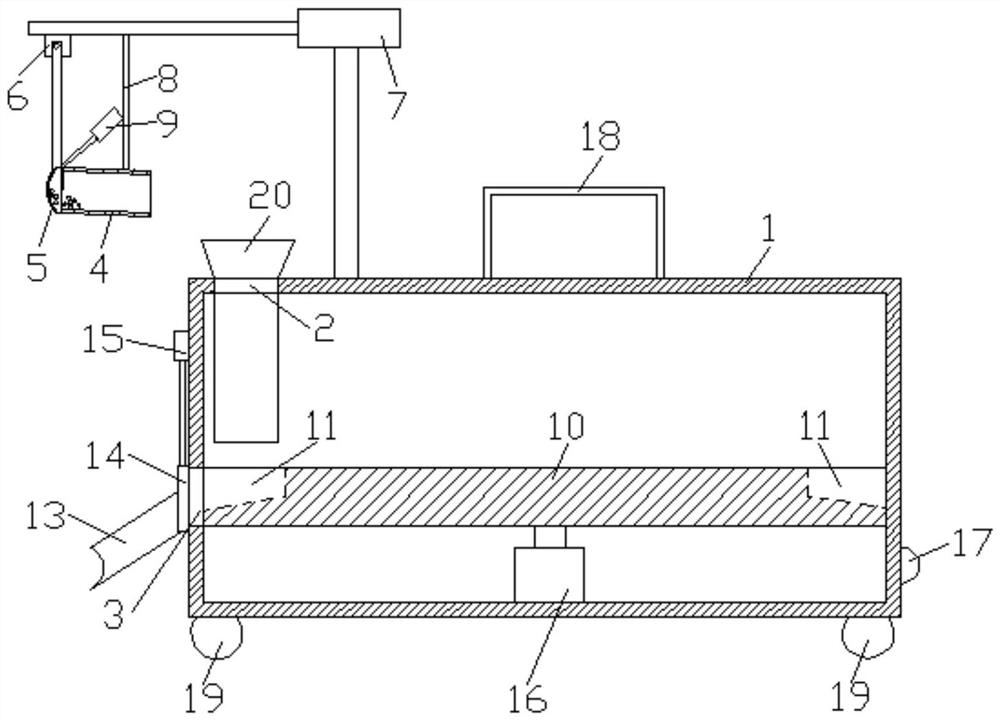

[0039]Such asfigure 1 As shown, on the basis of the above structure, in this embodiment, the sampling mechanism further includes a sampling scoop 5, which is mounted on one side of the sampling box 1 so as to swing up and down; flip the sampling cylinder 4 down until it is in a horizontal state, At the same time, swing the sampling spoon 5 up and down to take samples and send the sample to the sampling cylinder 4, then move the sampling cylinder 4 horizontally to the top of the sampling port 2, and flip the sampling cylinder 4 upwards to tilt so that the sample inside is from its outlet end Slide down into the injection port 2. When sampling food, turn the sampling cylinder 4 down until it is in a horizontal state, while swinging the sampling spoon 5 up and down to take samples and send the sample to the sampling cylinder 4, then move the sampling cylinder 4 horizontally to the top of the sampling port 2 and upward Turn over the sampling cylinder 4 to an inclined state so that the s...

Embodiment 2

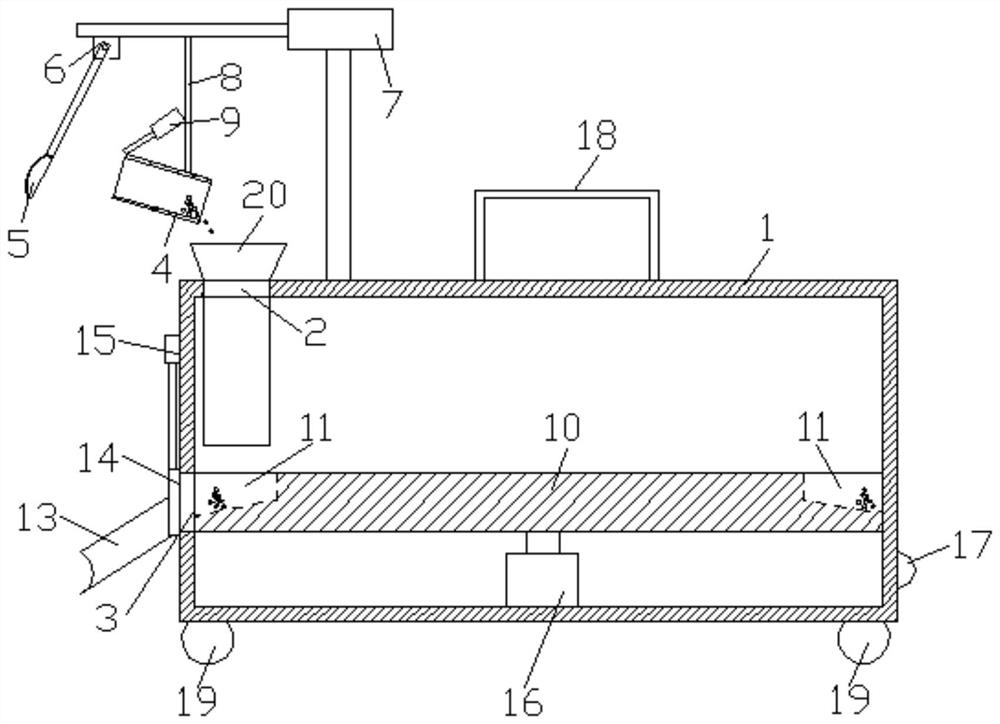

[0044]On the basis of the first embodiment, in this embodiment, a swing motor 6 is erected on one side of the sampling box 1. The output end of the swing motor 6 extends in the horizontal direction and is fixedly connected to one end of the sampling spoon 5, usually using bolts Or fixed connection by welding; the oscillating motor 6 drives the sampling spoon 5 to oscillate up and down to take samples and send them to the sampling cylinder 4. When sampling, the swing motor 6 drives the sampling spoon 5 to swing up and down to perform sampling and send it to the sampling cylinder 4, which has a high degree of automation and saves time and effort.

[0045]When the sampling scoop 5 is located above one side of the sampling box 1, the lower end of the bracket is welded to the sampling box 1, and the swing motor 5 is fixed to the upper end of the bracket by bolts. At this time, the above bracket will not affect the horizontal movement and up and down of the sampling cylinder 2. Flip.

Embodiment 3

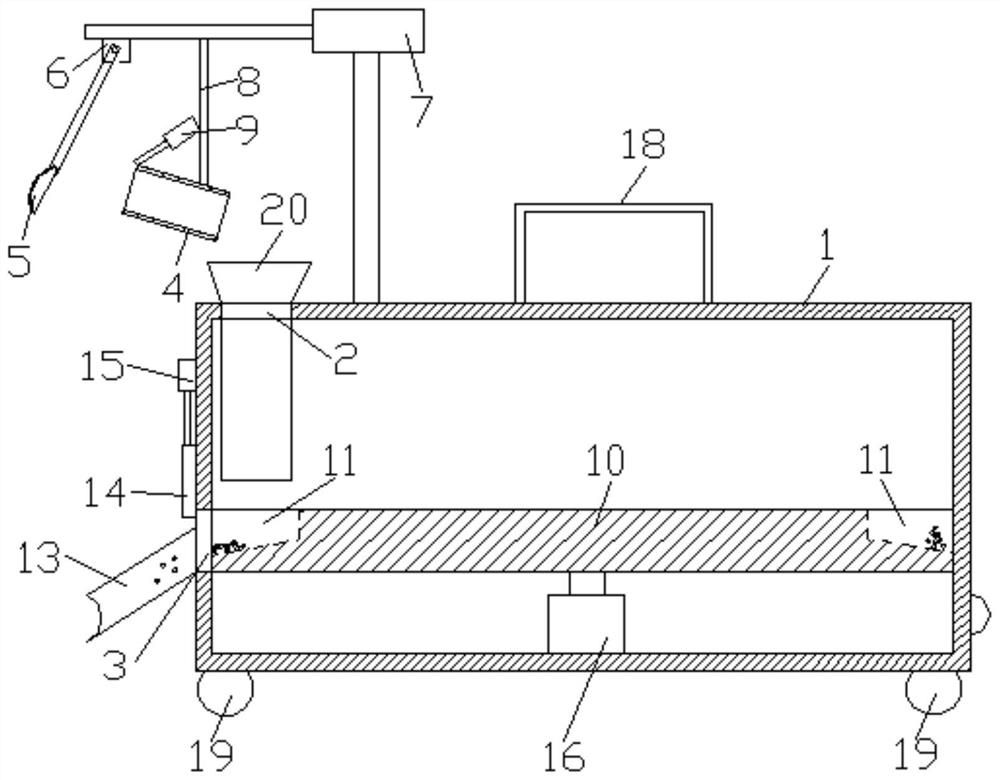

[0047]Based on the above structure, in this embodiment, a sampling cylinder 7 is installed on the top of the sampling box 1, and the sampling cylinder 7 is installed on the top of the sampling box 1 through a mounting frame. The upper and lower ends of the mounting frame are respectively connected to the top of the sampling box 1. It is welded to the sampling cylinder 7; the telescopic end of the sampling cylinder 7 extends in the horizontal direction and is fixedly connected (welded) to the upper end of the connecting rod 8. The sampling cylinder 4 is mounted on the lower end of the connecting rod 8 upside down. When sampling, the sampling cylinder 7 stretches and drives the sampling cylinder 4 to move horizontally for sampling. The sampling cylinder 7 and the sampling cylinder 4 are connected by a connecting rod to realize automatic sampling, which is convenient and quick to sample.

[0048]On the basis of the above solution, the sampling spoon 5 can also be installed at the telescop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com