Joint simulation optimization method and system for microwave microfluid sensor channel values

A microfluidic channel and co-simulation technology, applied in design optimization/simulation, instrumentation, electrical digital data processing, etc., can solve the problem of low sensitivity, achieve reliable performance, simplify the manual design process, and promote the effect of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

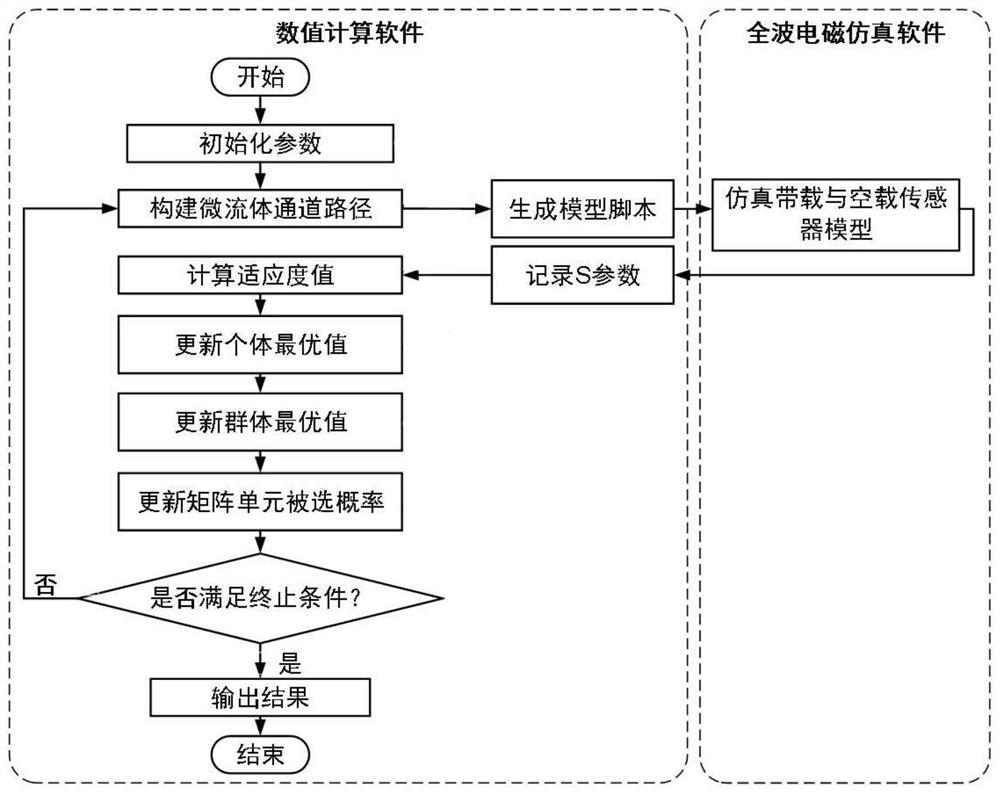

[0049] refer to figure 1 , the present embodiment provides a co-simulation optimization method for channel values of microwave and microfluidic sensors, comprising steps:

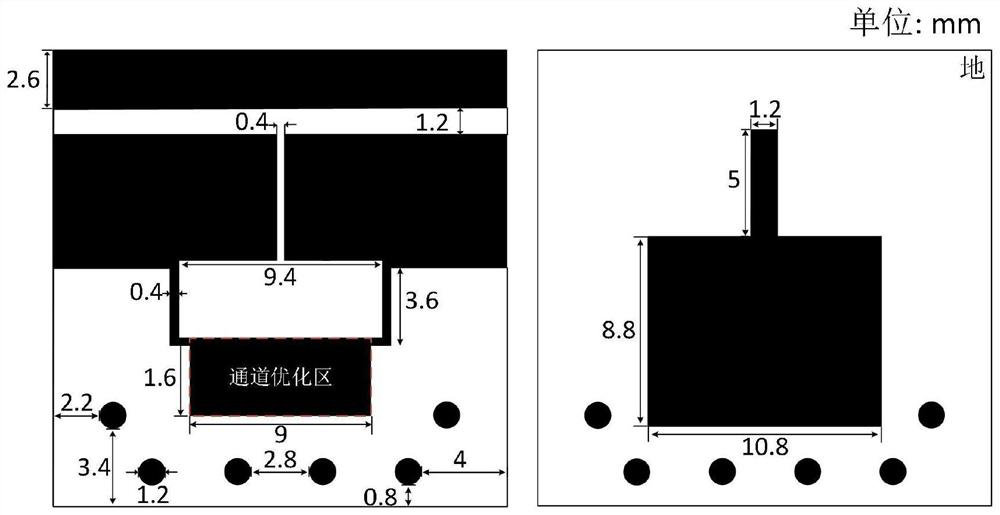

[0050] S1. Initially set the channel optimization area of the microwave and microfluidic sensor and pixelize it into a matrix unit of size MxN;

[0051] S2, initialization program parameter value;

[0052] S3. Construct a plurality of individual microfluidic channels according to the channel search method to form a population;

[0053] S4. Build a model and perform simulation, and calculate the fitness value of the individual microfluidic channel according to the data obtained by the simulation;

[0054] S5. Update the individual optimal channel, the group optimal channel and the probability of each matrix unit being selected in the iterative process according to the fitness value;

[0055] S6. Determine whether the number of iterations reaches the maximum number of iterations; if not, repeat the above...

Embodiment 2

[0080] refer to Figure 10 , the present invention also provides a co-simulation optimization system for microwave and microfluidic sensor channel values, including:

[0081] Initial setting module: Initially set the optimized area of the microwave and microfluidic sensor channel and pixelize it into a matrix unit of size MxN;

[0082] Initialize the module, initialize the program parameter value;

[0083] A channel building block that constructs a plurality of individual microfluidic channels to form a population according to a channel search method;

[0084] The fitness value calculation module constructs a model and performs simulation, and calculates the individual microfluidic channel fitness value according to the data obtained by the simulation;

[0085] The update module updates the individual optimal channel, the group optimal channel and the probability that each matrix unit is selected during the iterative process according to the fitness value;

[0086] Judgin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com