Joint simulation optimization method of microwave sensor based on electromagnetic surface unit structure

A microwave sensor and electromagnetic surface technology, which is applied in the field of co-simulation optimization of microfluidic sensors, can solve problems such as discontinuity, non-differentiability, and time and effort spent by researchers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

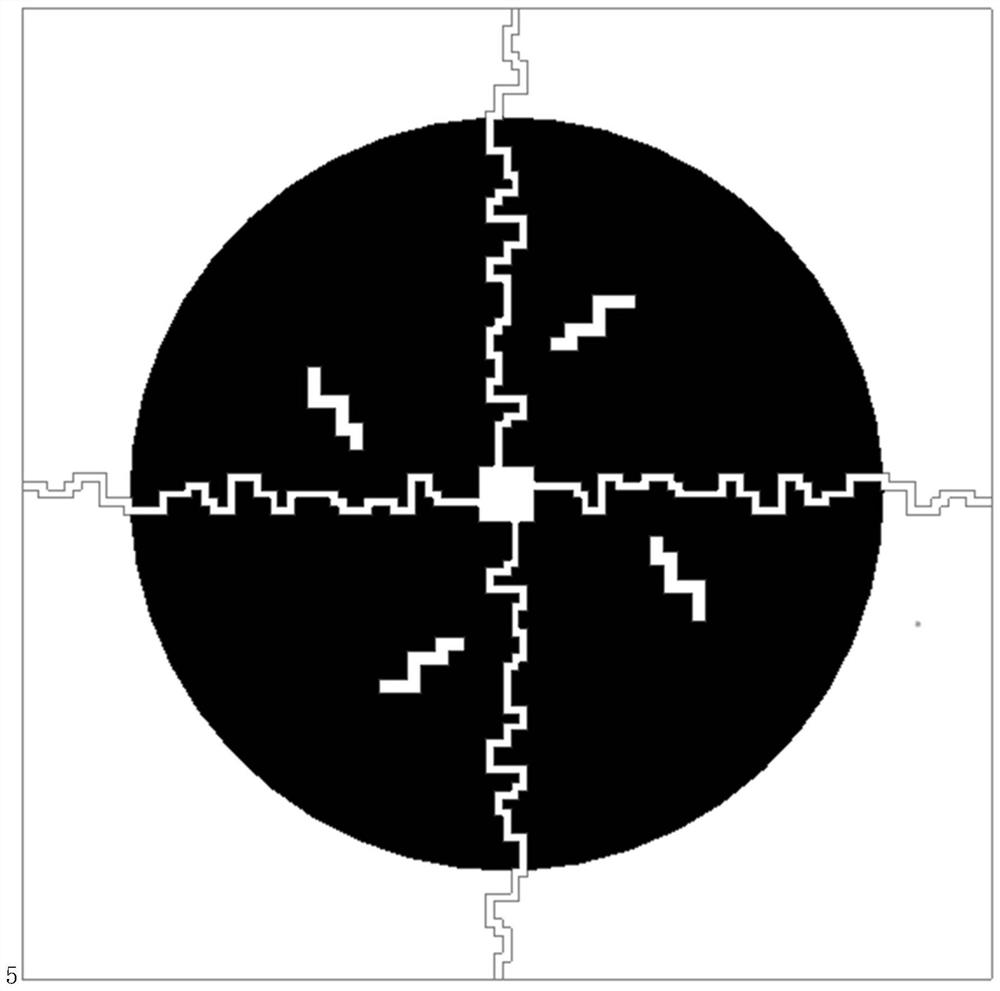

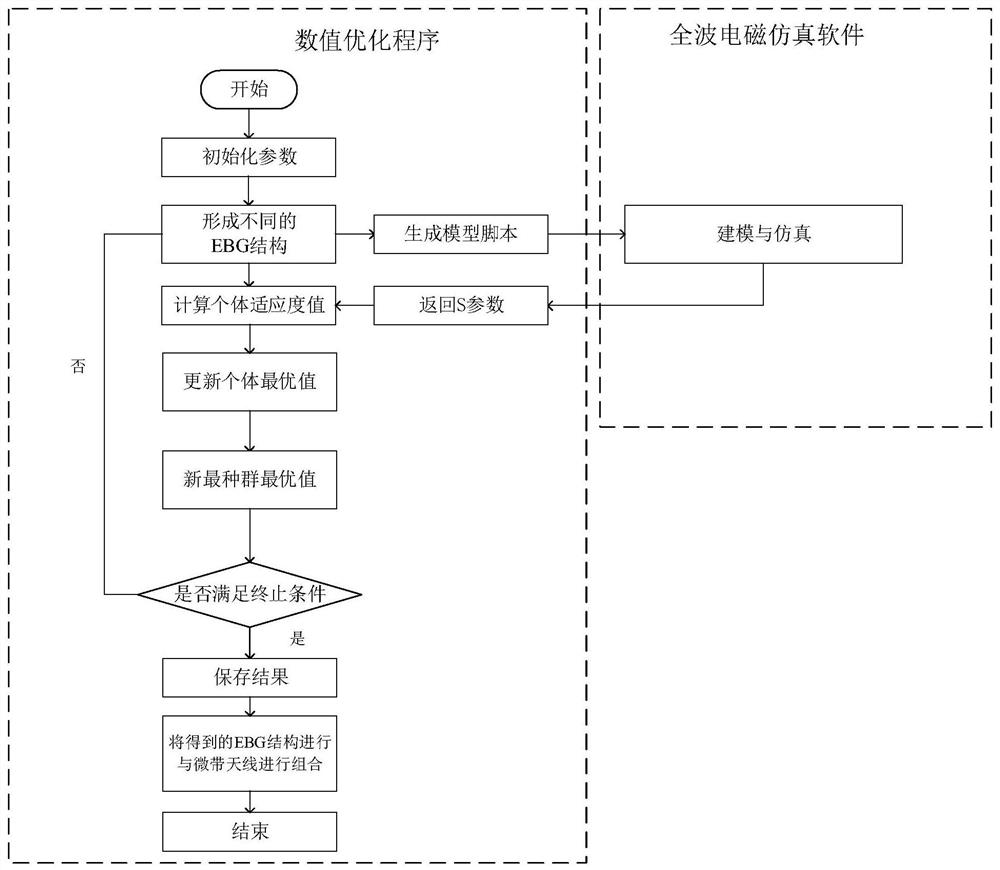

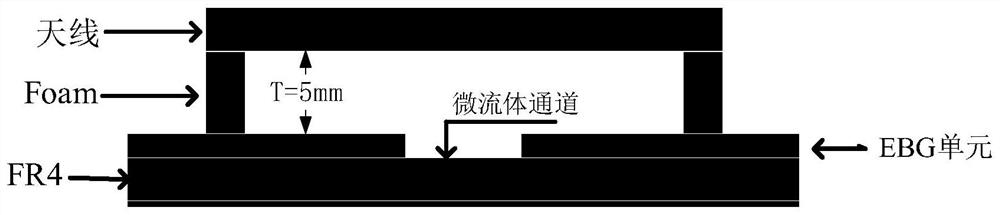

[0033] The microwave sensor co-simulation optimization method based on the electromagnetic surface unit structure of the present invention is to change the reflection phase of the structure based on different microfluids in the groove of the EBG structure, thereby causing the change of the resonant frequency of the antenna, and realizing the liquid samples with different dielectric constants achieved on the basis of measurements, figure 1 It is a schematic diagram of the microwave sensor structure based on the electromagnetic surface unit structure of the embodiment of the present invention. The optimization of the present invention is only for the partial area of the EBG surface and the electromagnetic performance part parameter structure and microfluidic channel. The remaining structural variable parameter values are in figure 1 Both of them hav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com