Power transmission line double-wire tackle

A transmission line, double-conductor technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of low work efficiency, many insecurity factors, and large distances, and achieve the effect of flexible and convenient operation, improved work efficiency, and labor-saving movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples, which are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

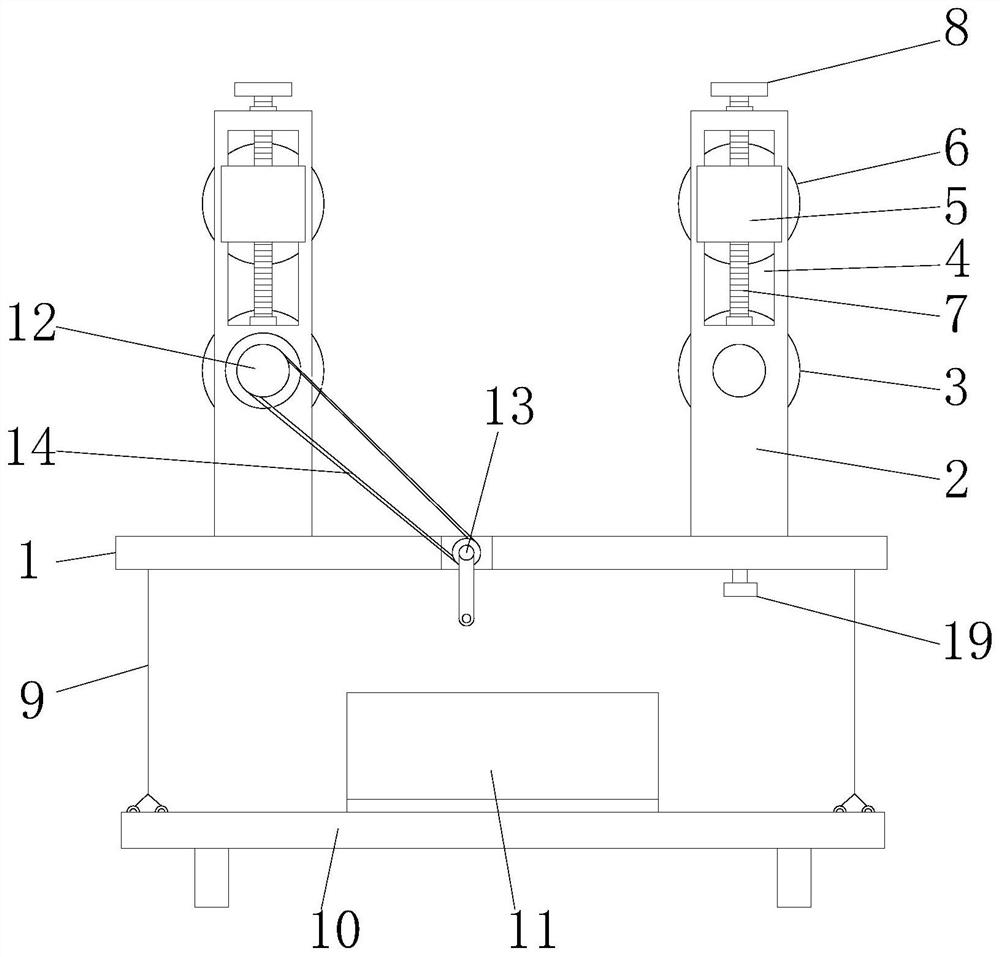

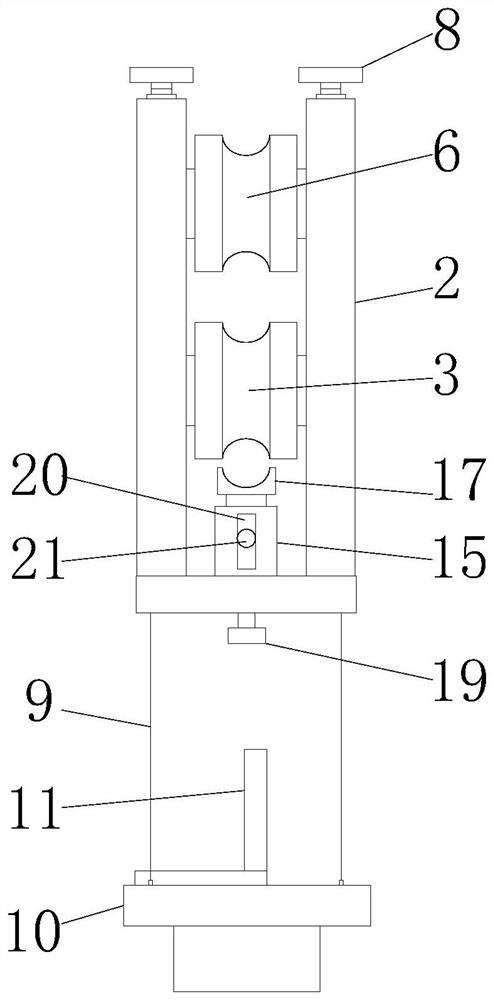

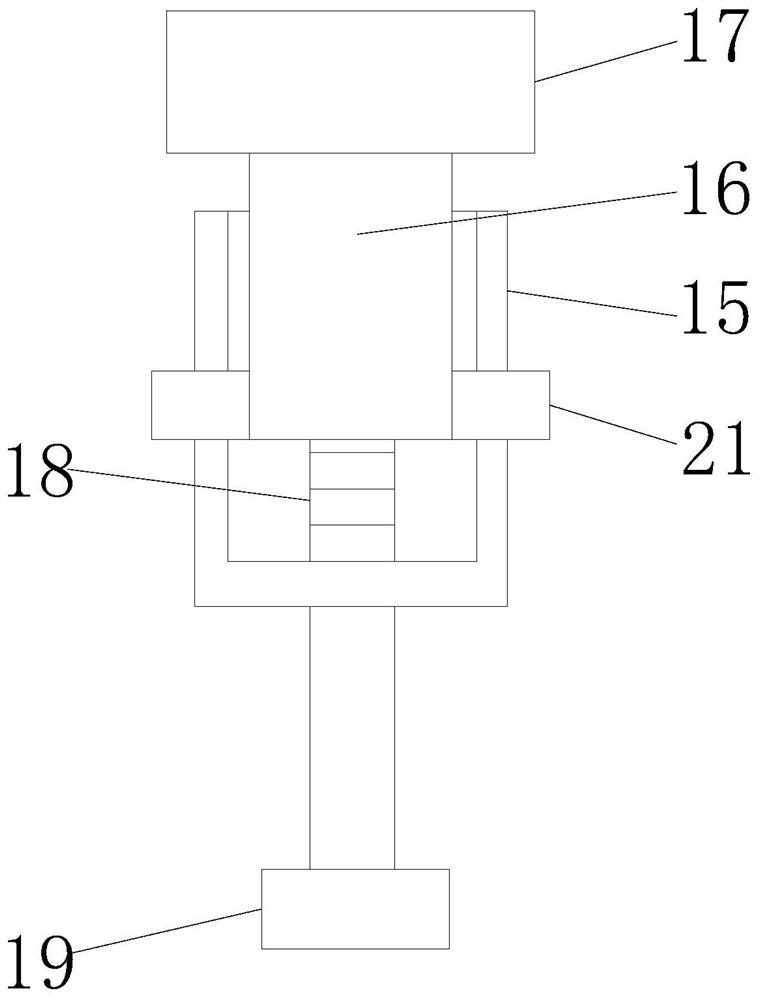

[0016] according to figure 1 , 2 As shown in . 2 and the first wire wheel 3, the support plate 2 is provided with two groups before and after, and the first wire wheel 3 is installed on the bottom between the support plates 2 of the two groups before and after, and the inside of the two groups of support plates 2 Above are provided with chute 4, and sliding block 5 is installed in the chute 4, the second wire pulley 6 is rotatably installed between the two groups of sliders 5, and threaded screw rod 7 is rotatably installed in the chute 4 , and threaded screw rod 7 runs through the slider 5 and is threadedly adapted, the upper end of the threaded screw rod 7 extends out of the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com