Pressure/temperature sensor

A technology of pressure temperature and sensors, which is applied to thermometers, measuring fluid pressure, and parts of thermometers, etc., and can solve problems such as measurement medium introduction deviation, pressure loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

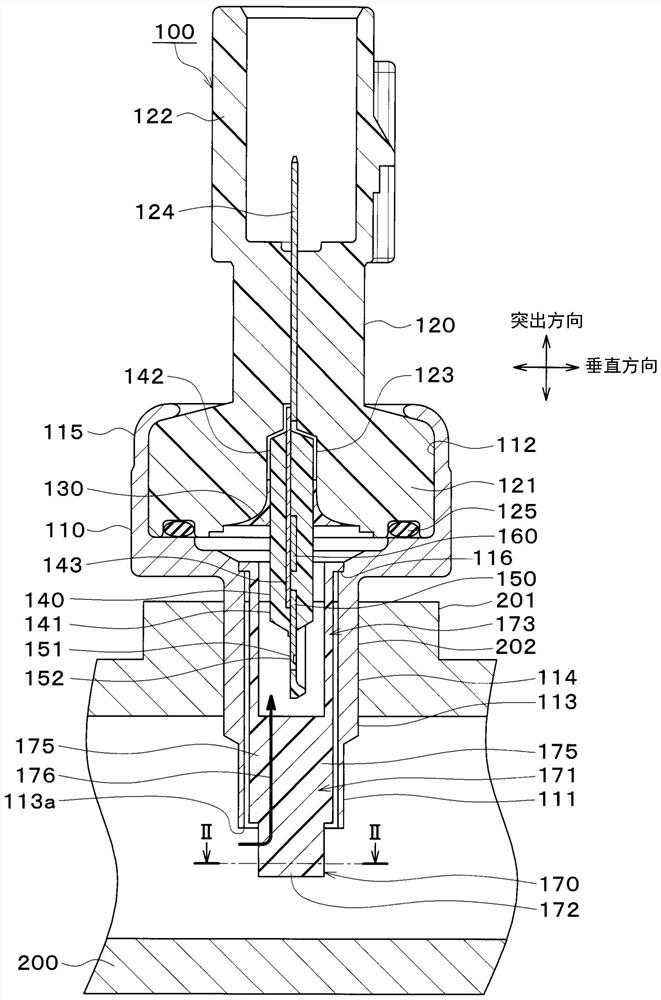

[0036] Hereinafter, a first embodiment will be described with reference to the drawings. The pressure temperature sensor of this embodiment can detect both the pressure and the temperature of the measurement medium. The pressure and temperature sensor is fixed to the piping, and detects the pressure and temperature of the measurement medium in the piping. The measurement medium is, for example, refrigerant used in automobiles. The measurement medium also includes lubricating oil such as engine oil and transmission oil, and gas.

[0037] Such as figure 1 As shown, the pressure temperature sensor 100 includes a housing 110 , a sensor body 120 , a potting portion 130 , a molded resin portion 140 , a sensor chip 150 and an introduction portion 170 .

[0038] The housing 110 is a hollow shell formed by machining a metal material such as SUS by cutting or the like. The housing 110 has a protruding portion 111 on one end side and an opening portion 112 on the other end side. The...

no. 2 Embodiment approach

[0076] In this embodiment, differences from the first embodiment will be described. Such as Figure 12 As shown, the introduction portion 170 has a planar tapered surface 180 . The blade surface 174 of the blade 175 and the fixed surface 177 of the base 172 are connected at the tapered surface 180 . This makes it possible to easily move the measurement medium entering the acute-angle portion formed by the adjacent blades 175 toward the sensor chip 150 along the tapered surface 180 .

[0077] As a variant, such as Figure 13 As shown, the introduction portion 170 may have a curved surface 181 . The curved surface 181 is a curved surface that is recessed toward the corner connecting the blade surface 174 of the blade 175 and the fixing surface 177 of the bottom 172 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com