Steel structure bridge box welding positioning device

A welding positioning and steel structure technology, applied in welding equipment, auxiliary devices, welding equipment, etc., can solve the problems of unstable welding quality, spatter, and large environmental impact, reduce welding difficulty and strength, and improve the accuracy of return performance, improve welding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

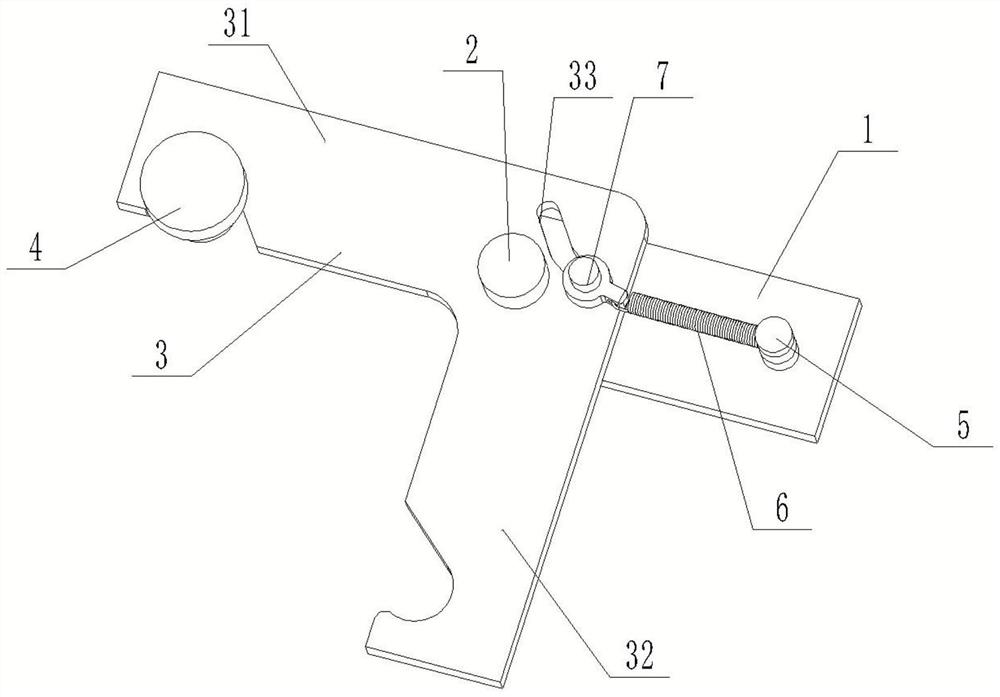

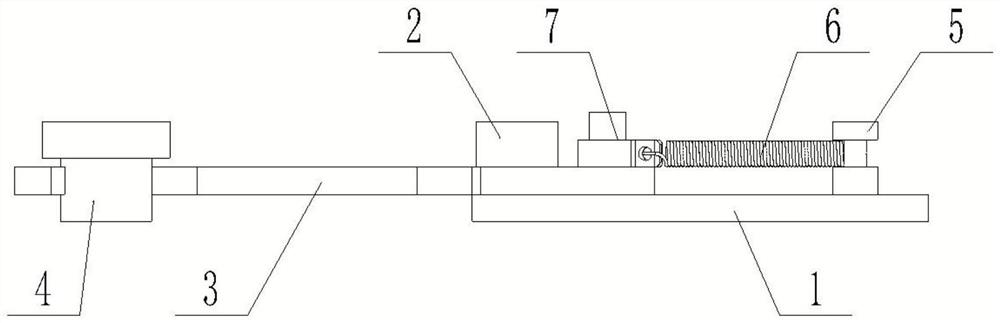

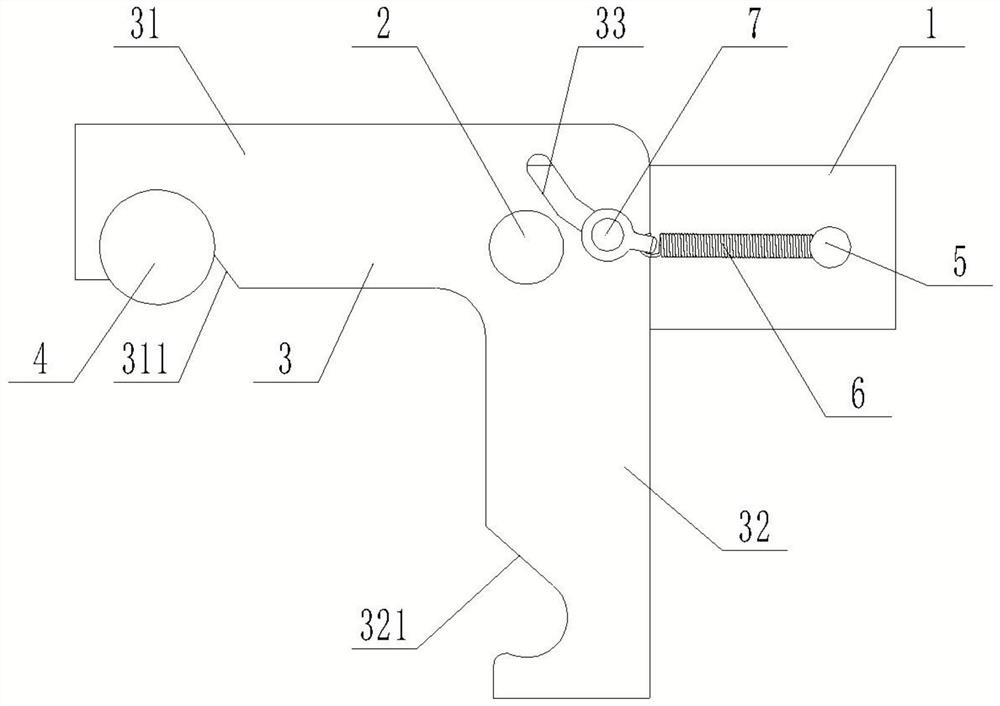

[0024] Such as Figure 1-Figure 4 As shown, a steel structure bridge box welding positioning device includes a rectangular positioning plate 1 arranged along the extension direction of the weld seam. One end of the positioning plate 1 in the length direction is connected to a rotating shaft 2, and the rotating shaft 2 is sleeved with a The movable baffle 3 that the shaft 2 rotates, the movable baffle 3 includes a first baffle 31 and a second baffle 32, the first baffle 31 and the second baffle 32 are L-shaped, and the L-shaped cavity is along the positioning plate 1 The limit block 4 is arranged in the length direction, the rotating shaft 2 is located at the junction of the first baffle 31 and the second baffle 32, the movable baffle 3 is parallel to the ground, and the end of the positioning plate 1 in the length direction away from the rotating shaft 2 is provided with a return fixing A return spring 6 is connected between the rod 5 and the return fixed rod 5 and the movable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com