Timber cutting machine

A wood cutting machine, intermediate position technology, applied in sawing equipment, wood processing appliances, circular saws, etc., can solve problems such as damage to wood, jitter, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

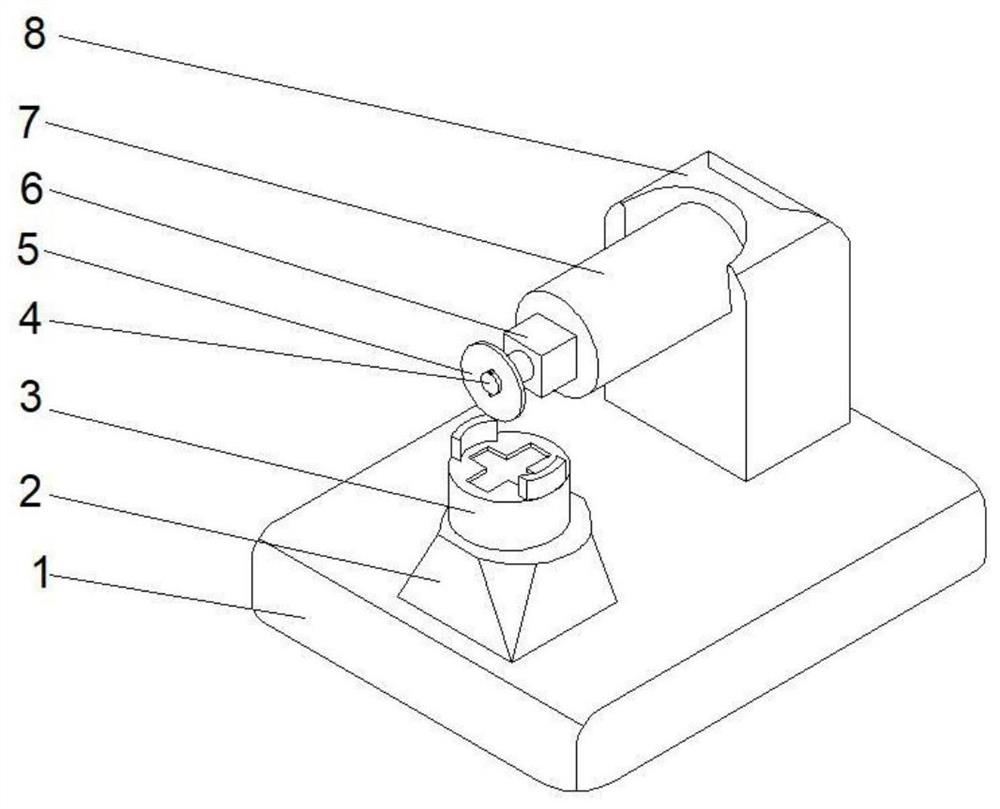

[0035] Such as Figure 1-2 , a wood cutting machine proposed by the present invention, comprising a base 1, a column 8 is fixedly connected to the middle position on the top right side of the base 1, and a force arm 7 is arranged on the left side of the top of the column 8, and the force arm 7 is far away from the middle position of one end of the column 8 A motor 6 is fixedly connected, and the output shaft of the motor 6 is rotatably connected to a connector 4. The outer surface of the connector 4 is fixedly connected to a cutter 5. An adjustment device 2 is arranged at the middle position on the left side of the top of the base 1, and the top of the adjustment device 2 is fixed. A connecting device 3 is connected.

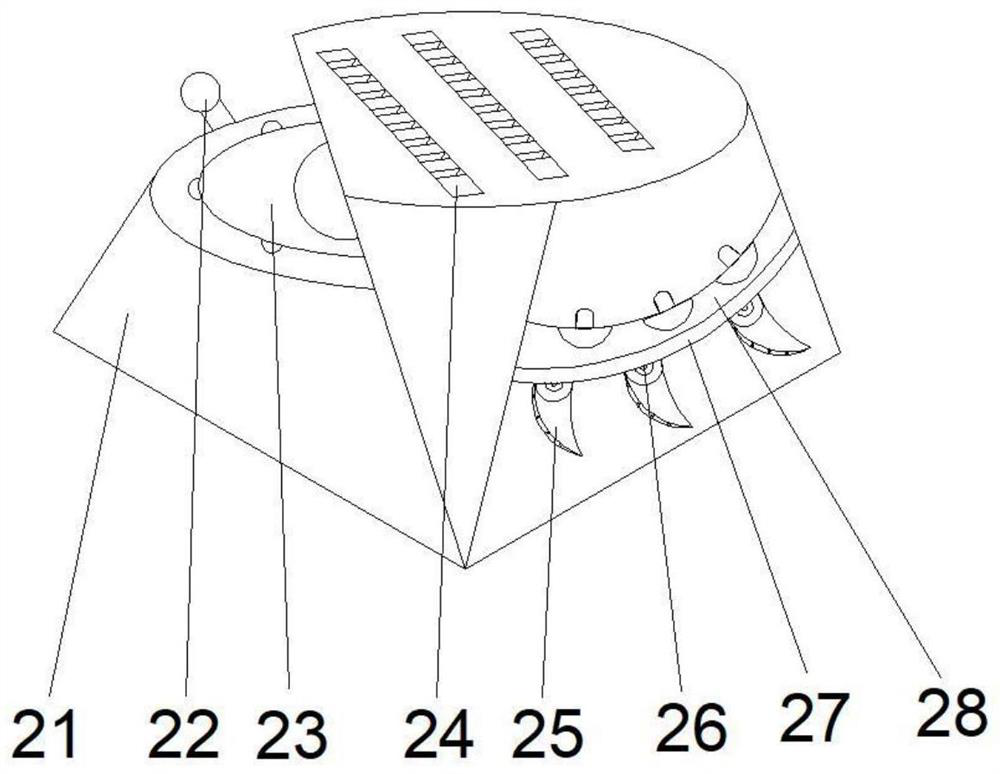

[0036] Wherein, the adjustment device 2 includes an outer frame 21, a connecting groove 24 is opened in the middle of the top of the outer frame 21, a rotating rod 22 is arranged in the left middle part of the outer frame 21, and an adjusting rod 22 is arranged ...

Embodiment 2

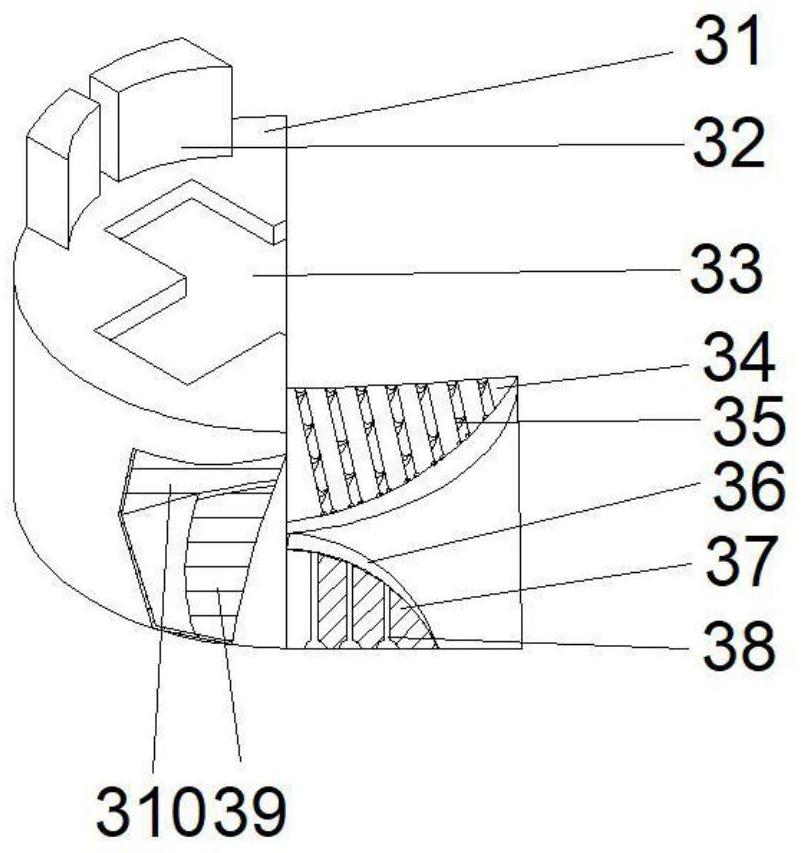

[0039] Such as Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the connection device 3 includes an outer frame 31, a groove 33 is opened in the middle of the top of the casing 31, and the top of the casing 31 is located on both sides of the groove 33 A stopper 32 is provided, a plate 38 is fixedly connected to the middle position of the bottom of the inner cavity of the shell 31, and a display plate 36 is fixedly connected to the top of the plate 38. The middle of the bottom of the inner cavity of the shell 31 is located on both sides of the plate 38 and a guide cavity 36 is provided. The middle of the inner cavity bottom of the housing 31 is located on the left side of the display board 36 and is fixedly connected with a side plate 39, and the top of the side board 39 is fixedly connected with a top board 310, and the top of the display board 36 is provided with a swing plate 35, and the inside of the swing plate 35 is p...

Embodiment 3

[0042] Such as Figure 1-6 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the top of the inner cavity of the frame 28 is provided with a guide block 283, and the top of the guide block 283 penetrates the frame 28 and extends to the outside of the frame 28 The top of the inner chamber of the frame 28 is fixedly connected with push blocks 282 on both sides of the guide block 28 , and the bottom of the frame 28 is located on both sides of the push block 282 and is provided with circumscribed balls 281 .

[0043] Wherein, the adjustment ring 23 includes a connecting ring 231, the inner surface of the connecting ring 231 is provided with a connecting block 232, the top of the connecting block 232 penetrates the connecting ring 231 and extends to the inside of the connecting ring 231, and the connecting block 232 is fixedly connected to one end away from the connecting ring. Force plate 233 is arranged.

[0044] Wherein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com