A bucket wheel machine automatic control method and system based on collapse detection

An automatic control system, bucket wheel machine technology, applied in the direction of conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problem of low operating level of the driver, inability to accurately and timely control the bucket wheel machine to avoid collapse, current feedback Insufficient stability and other problems, to achieve the effect of high degree of automation, low cost and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

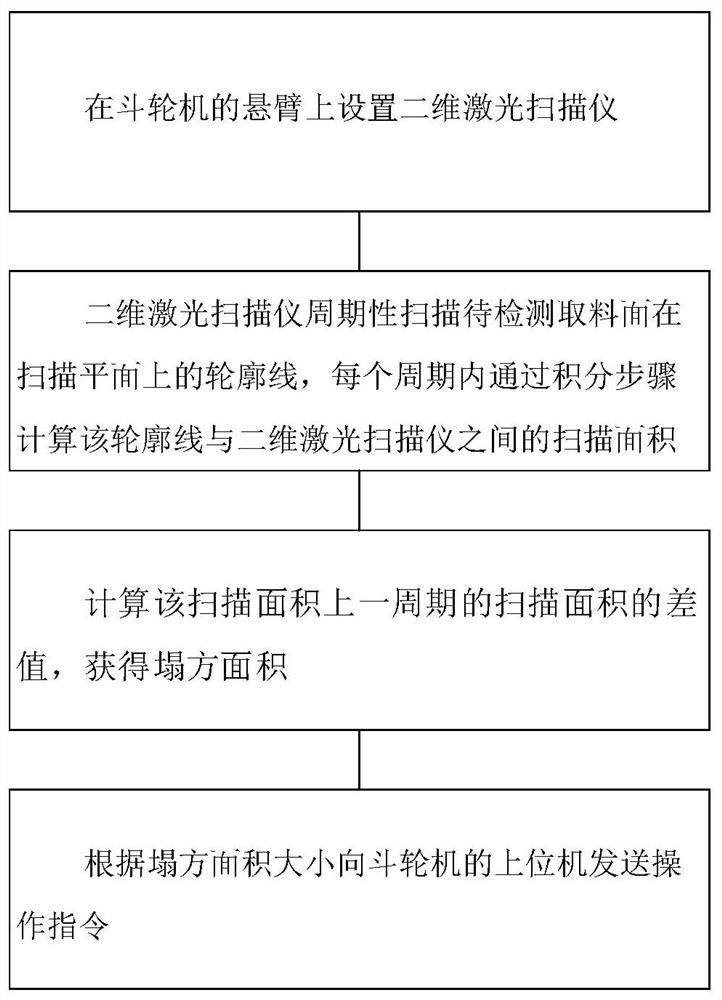

[0037] An automatic control method of bucket wheel machine based on collapse detection, such as figure 1 and Figure 8 ,Specifically:

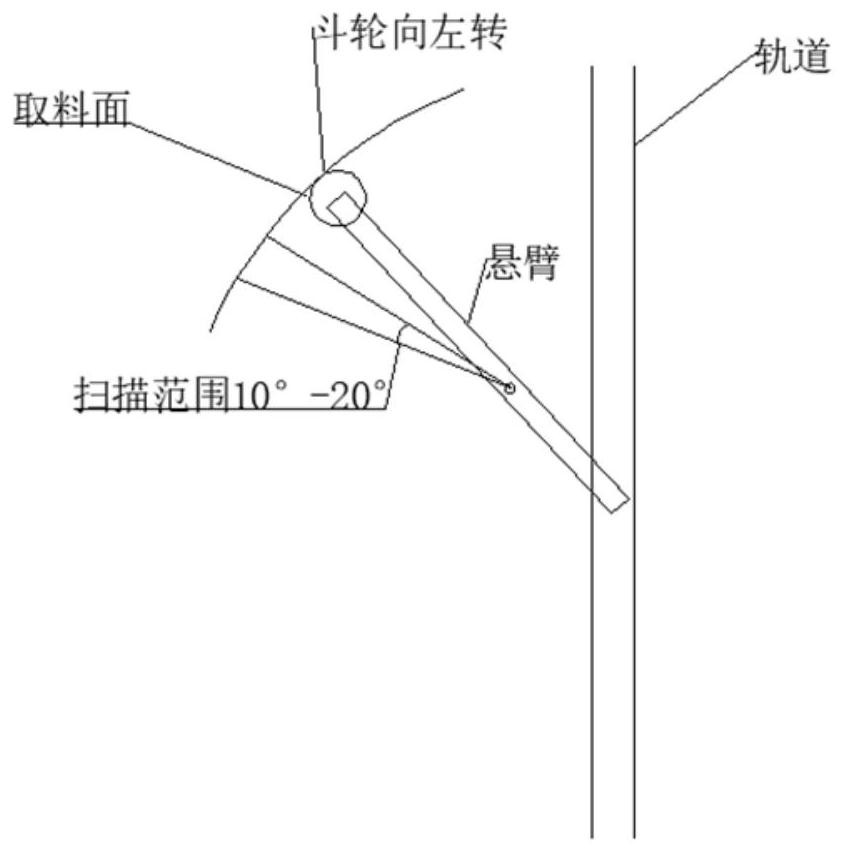

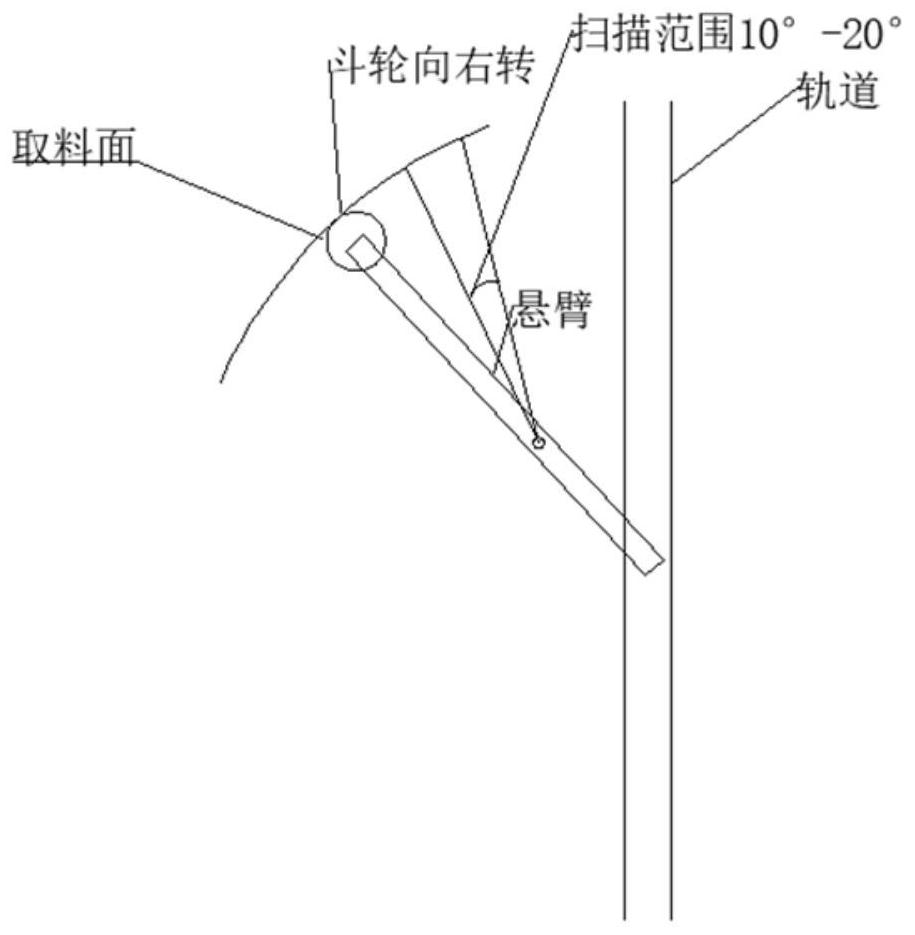

[0038] A two-dimensional laser scanner 1 is set on the cantilever of the bucket wheel machine, the cantilever can perform rotary motion and pitching motion, and the plane where the cantilever swings is the scanning plane;

[0039] The two-dimensional laser scanner 1 periodically scans the outline of the material taking surface to be detected on the scanning plane, the current rotation direction of the cantilever is towards the material taking surface to be detected, and the current rotation direction of the cantilever is obtained according to the upper computer of the bucket wheel machine;

[0040] Calculating the scan area between the contour line and the two-dimensional laser scanner 1 through an integration step in each cycle;

[0041] Calculate the difference between the scanning area and the scanning area of the previous cycle to obta...

Embodiment 2

[0049] A bucket wheel machine automatic control system based on collapse detection corresponding to Embodiment 1, including a contour scanning module, a collapse detection module and an operation control module:

[0050] The contour scanning module is used to scan the contour line of the feeding surface to be detected on the scanning plane through the two-dimensional laser scanner 1. The scanning plane is the plane where the cantilever swings, and the current rotation direction of the cantilever is towards the feeding surface to be detected. The angle between the scanning direction of the 2D laser scanner 1 and the cantilever is within 10° to 20°, so as to ensure that before the cantilever of the bucket wheel machine reaches the scanning range of the 2D laser scanner 1, it can be judged in time whether there is a landslide on the feeding surface to be detected. The upper computer of the bucket wheel machine has enough time to complete the operation instructions, and the safety ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com