Cable type friction damper with variable friction coefficient

A friction damper and friction coefficient technology, which is used in protective buildings/shelters, building components, earthquake-proof and other directions, can solve the problems of increasing the number of friction dampers, increasing the seismic energy input, and increasing the lateral stiffness of the structure. , to achieve the effect of reducing the installation cost of equipment and the number of dampers installed, reducing the increase effect, and increasing the energy consumption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

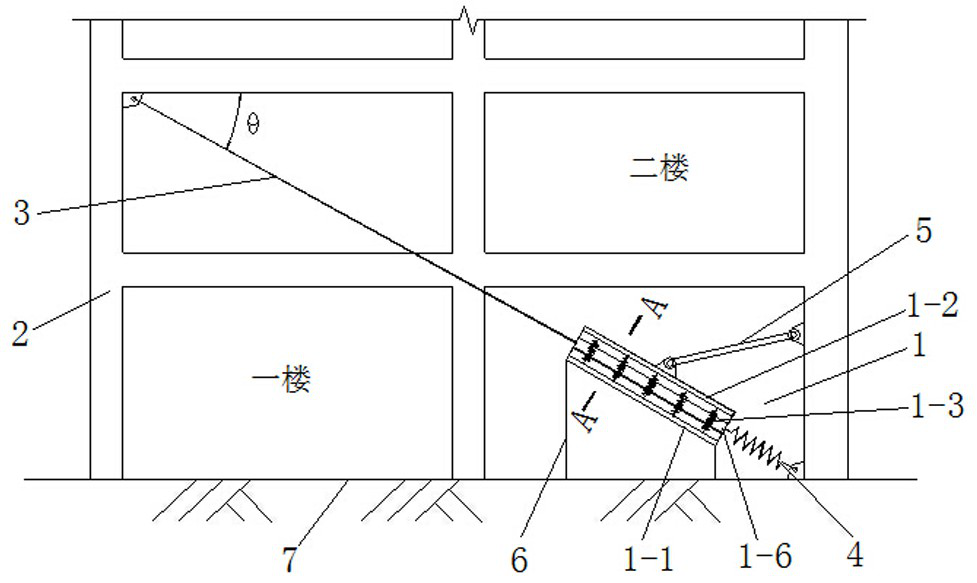

[0013] Attached below Figure 1 ~ Figure 2 And embodiment the present invention is described in further detail.

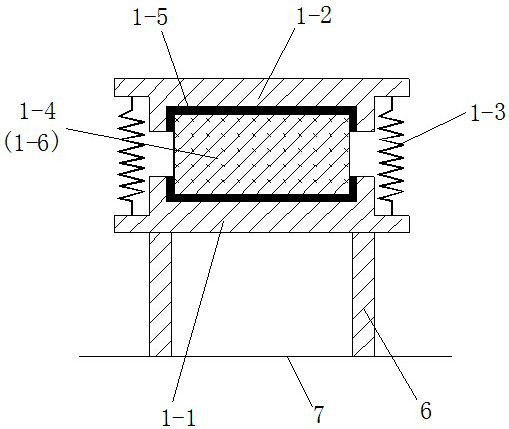

[0014] refer to Figure 1-2 , this embodiment includes a friction damper body 1, the friction damper body 1 obliquely connects the upper left end and the lower right corner of the building 2, and the friction damper body 1 includes a damper chassis 1-1 and a damper upper cover 1-2, the damper chassis 1-1 and the damper upper cover 1-2 are flexibly connected through the pressure springs 1-3 on the left and right sides, and the pressure springs 1-3 are provided with multiple groups on the left and right sides , the damper chassis 1-1 and the middle part of the damper upper cover 1-2 form a cavity 1-4, and the inner circumference of the cavity 1-4 is fixed with a cushion layer 1-5 with a variable friction coefficient in the forward and reverse directions , there is a movable metal block 1-6 inside the cavity 1-4, and the metal block 1-6 is clamped between the damper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com