Power distribution cabinet detection device and method for production line

A technology for detection devices and power distribution cabinets, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as non-housing detection, and achieve the effects of ensuring effectiveness, improving efficiency and quality, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

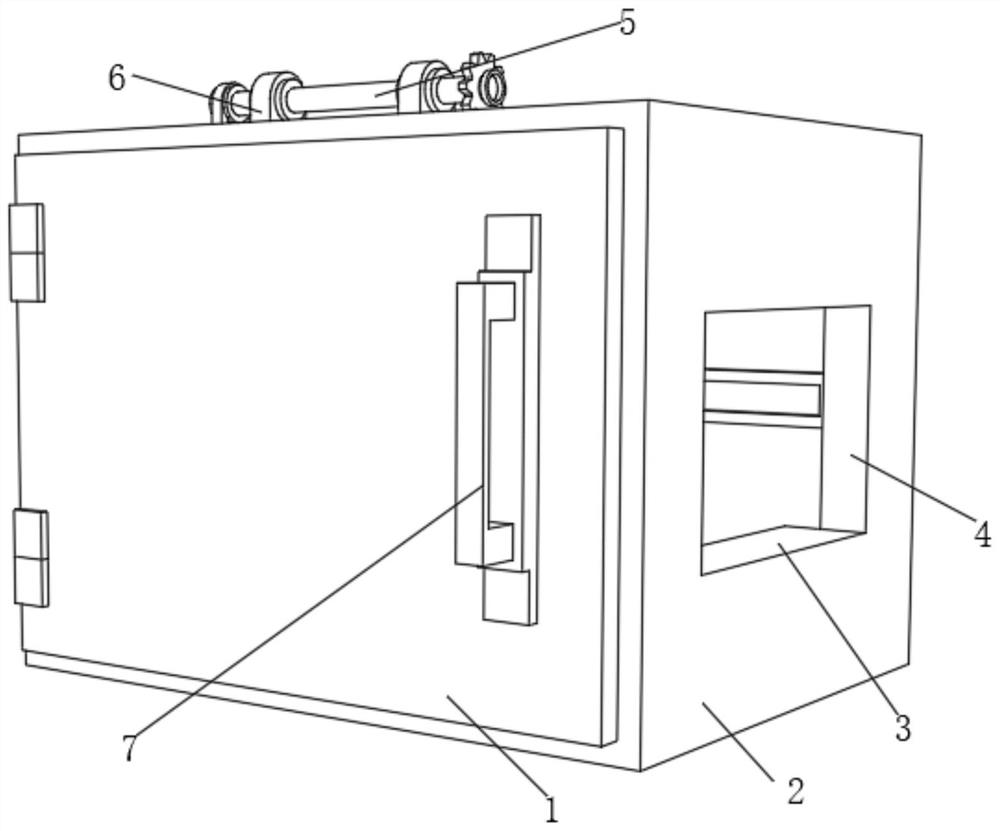

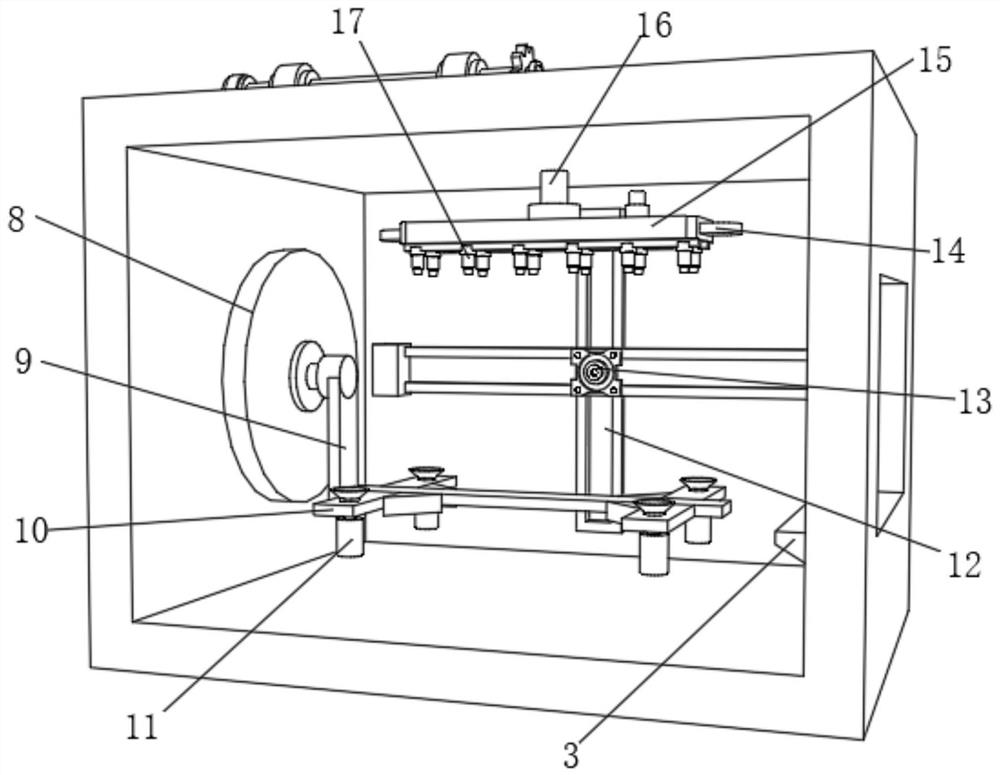

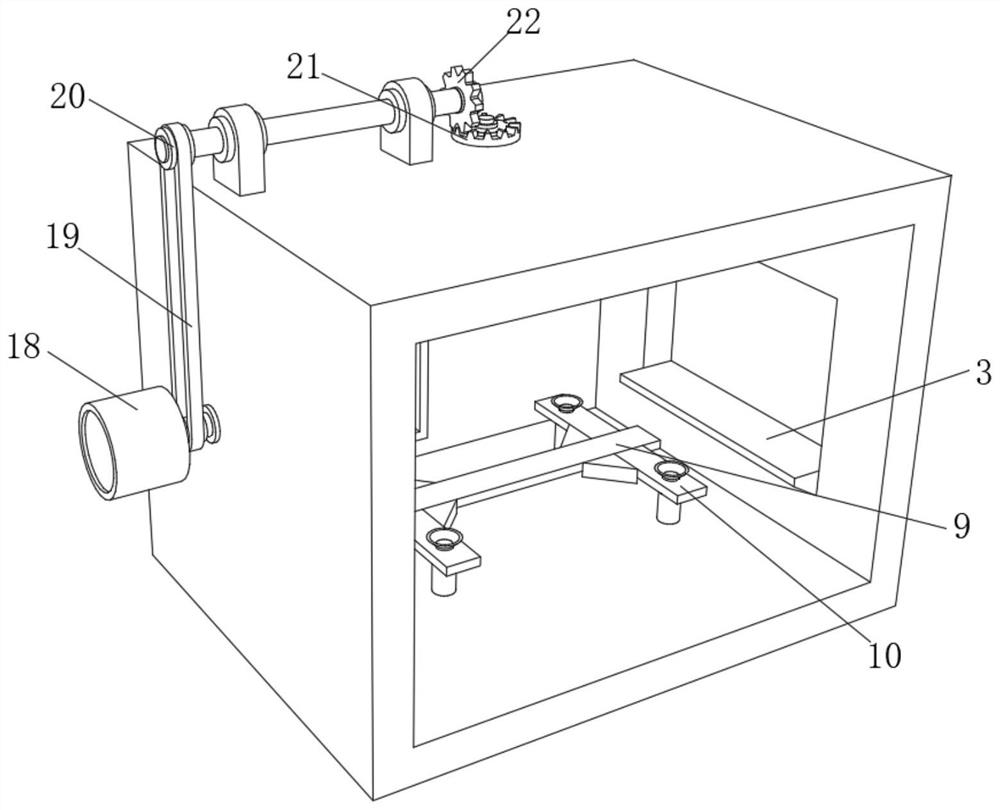

[0038] A detection device for a power distribution cabinet on a production line, such as Figure 1-5 As shown, it includes a detection box 2, the front outer wall of the detection box 2 is connected with a door 1 through a hinge, and the outer wall of the front side of the door 1 is fixed with a handle 7 by bolts, and the outer wall of the detection box 2 is opened with an inlet. The feed port 4, and the outer wall of the bottom side of the feed port 4 is provided with a material guide plate 3, and the side and top of the detection box 2 are provided with a driving mechanism, and the inner wall of the driving mechanism near the top of the detection box 2 is threadedly connected with a rotating shaft. Rod 16, the bottom outer wall of rotating rod 16 is connected with gas collection box 15 by shaft coupling, and gas collection box 15 top side outer wall is provided with air guide tube, and the both sides of gas collection box 15 are all provided with telescopic guide plate 14, an...

Embodiment 2

[0044] A detection method for a power distribution cabinet detection device on a production line, comprising the following steps:

[0045] S1: fill the gas collecting box 15 with natural gas through the air guide pipe;

[0046] S2: import the power distribution cabinet to be detected into the detection box 2 through the feed port 4, and start the fixing component to fix it;

[0047] S3: Start the driving mechanism, and the driving mechanism drives the rotating rod 16 on the inner wall of the top of the detection box 2 to rotate, and the rotating rod 16 drives the gas collecting box 15 to rotate, and at the same time starts a plurality of fire nozzles at the bottom of the gas collecting box 15;

[0048] S4: During this period, the drive mechanism also drives the intermittent rotation mechanism to work, and the intermittent rotation mechanism effectively drives the fixed components to make regular rotation movements, making the power distribution cabinet do intermittent rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com