Ceramic body defect detection device and method based on acoustics

A defect detection, ceramic body technology, applied in the direction of measuring devices, generation of ultrasonic/sonic/infrasonic waves, analysis of solids using sound waves/ultrasonic/infrasonic waves, etc., can solve the problems of low objective consistency, slow speed, and high cost of non-destructive testing equipment , to achieve objective consistency of results, simple detection process, and effective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

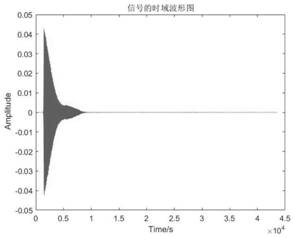

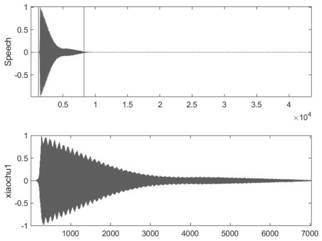

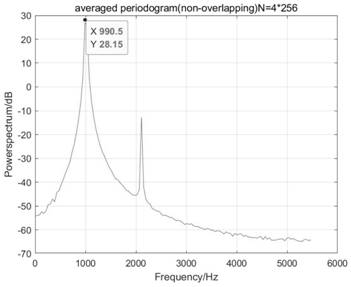

[0038] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0039] like Figure 1 to Figure 3 As shown, the bottom of the device is surrounded by aluminum profiles to form a rectangular base, and four aluminum profiles are erected in the middle, two parallel, with different heights, used as support rods for the mallet and electromagnet, and all profiles are connected and fixed by corner fittings. Fix the adsorption sheet on one side of the mallet through countersunk bolts, connect the mallet to the drive shaft through a connector, and insert the pinion into one end of the drive shaft. Both ends of the shaft are connected to the aluminum support frame through bearings and bearing seats, and on a horizontal plane, 1 / 4 and 3 / 4 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com