Method and device for detecting width of rail joint seam of steel rail

A technology for rails and rail joints, applied in the field of rail transit, can solve the problems of high labor cost, no solution proposed, slow detection speed, etc., and achieve the effect of improving efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

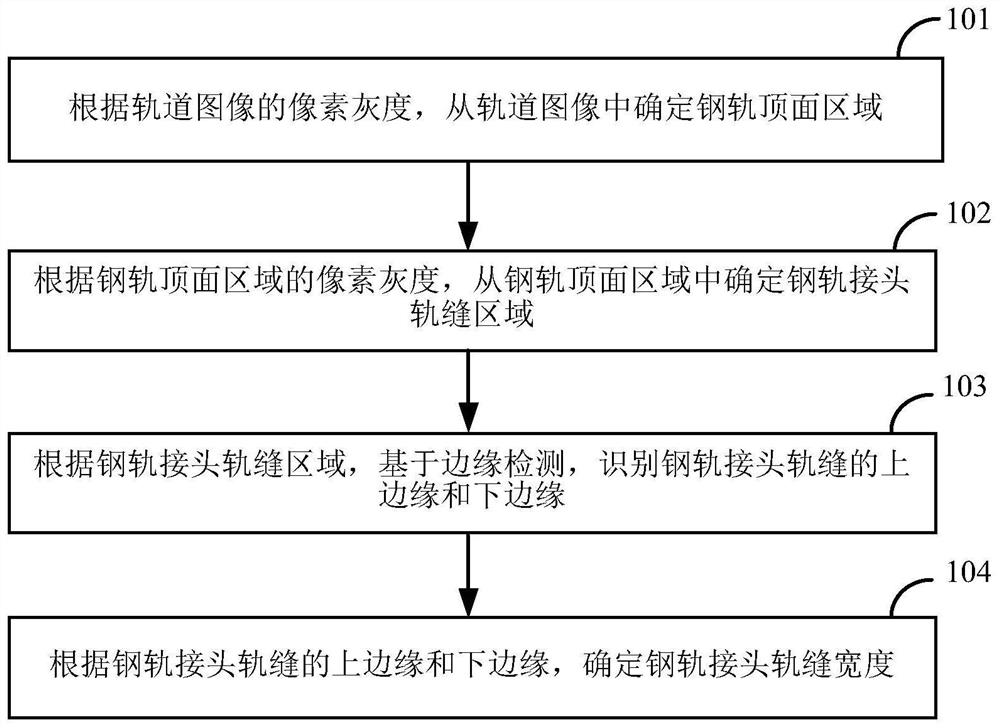

[0034] In order to solve the existing technical problem of low efficiency and accuracy in detecting the width of the rail joint based on manual inspection, the embodiment of the present invention provides a detection method for the width of the rail joint rail to improve the detection of the width of the rail joint. efficiency and accuracy, figure 1 It is a schematic diagram of the detection method flow chart of the rail joint rail gap width in the embodiment of the present invention, as figure 1 As shown, the method includes:

[0035] Step 101: Determine the rail t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com