High electron mobility transistor

A high electron mobility, transistor technology, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as the decrease of electron density in two-dimensional electron gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

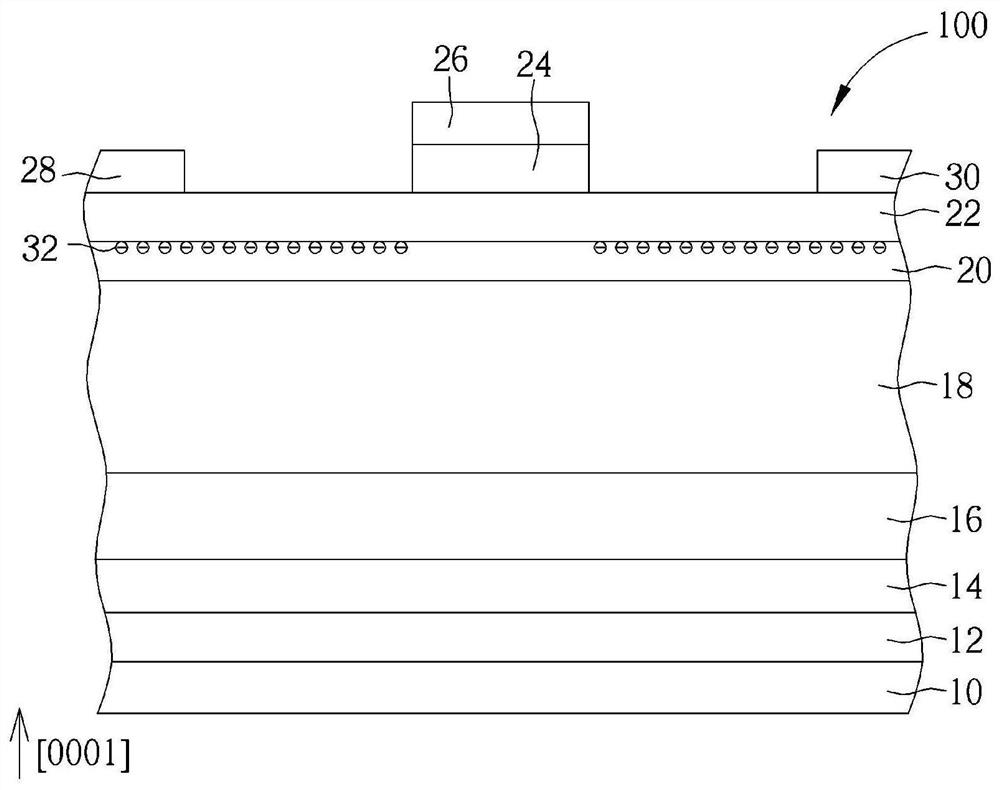

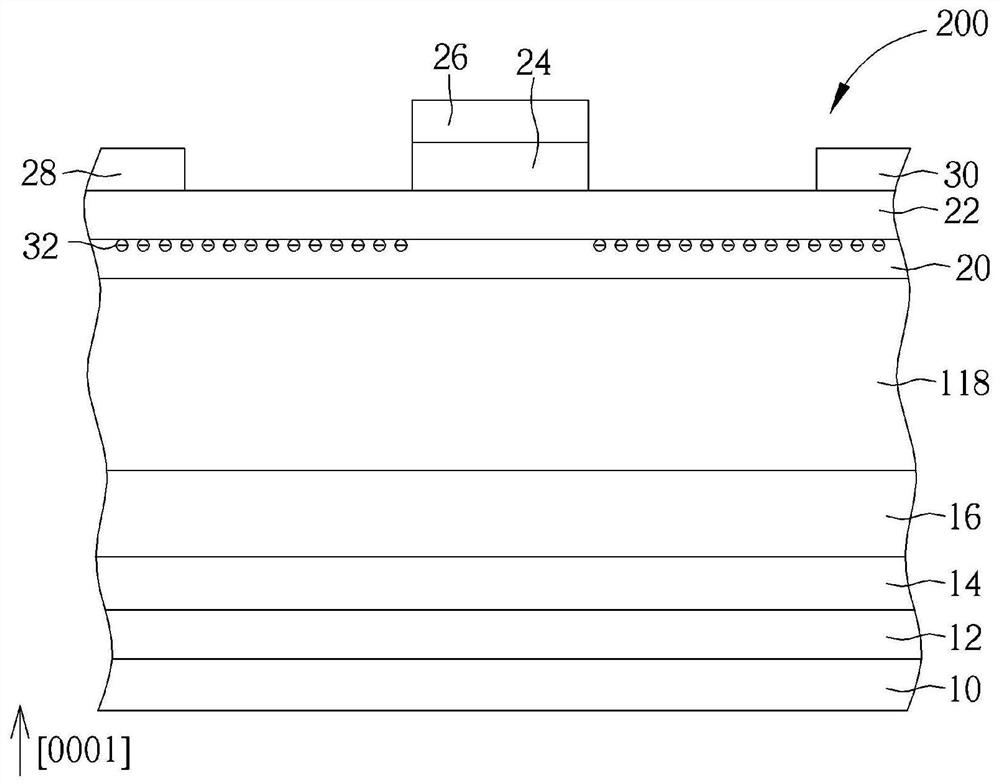

[0032] figure 1 It is a high electron mobility transistor according to the first preferred embodiment of the present invention.

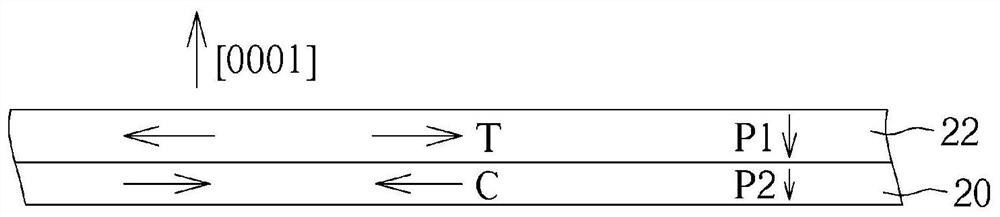

[0033] Such as figure 1 As shown, a high electron mobility transistor 100 includes a substrate 10, such as a silicon substrate. A nucleation layer 12 is arranged on the silicon substrate 10, a transition layer 14 is arranged on the nucleation layer 12, a superlattice layer 16 is arranged on the transition layer 14, a zinc oxide (ZnO) layer 18 is arranged on the superlattice (superlattice) layer 16, a gallium nitride (GaN) layer 20 is arranged on the zinc oxide layer 18 and the gallium nitride layer 20 contacts the zinc oxide layer 18, an aluminum gallium nitride (Al x Ga 1-x The N) layer 22 is disposed on the GaN layer 20 and the AlGaN layer 22 contacts the GaN layer 20, and a P-type GaN layer 24 is disposed on the AlGaN layer. A gate electrode 26 is disposed on the P-type GaN layer 24 , a source electrode 28 and a drain electrode 30 are dispose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com