Preparation method of negative electrode lead plaster of lead-acid storage battery and negative electrode plate

A lead-acid battery and negative electrode paste technology, applied in the direction of lead-acid battery electrodes, battery electrodes, chemical instruments and methods, etc., can solve the problems of reduced electrochemical activity, end of battery life, etc., to reduce energy consumption and water consumption , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

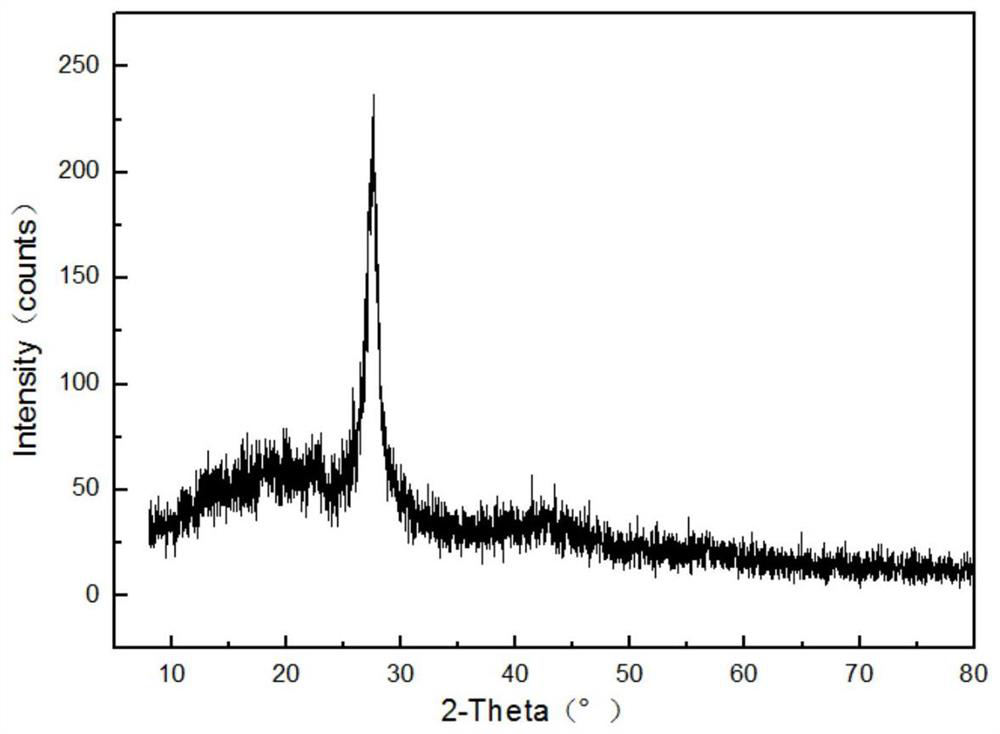

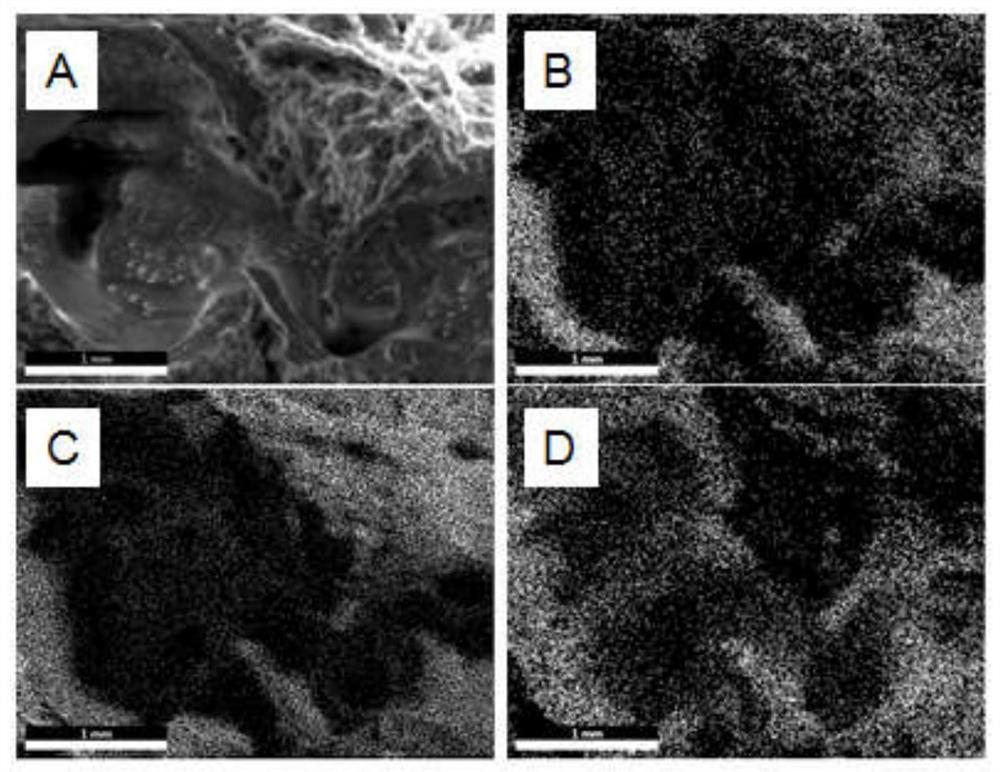

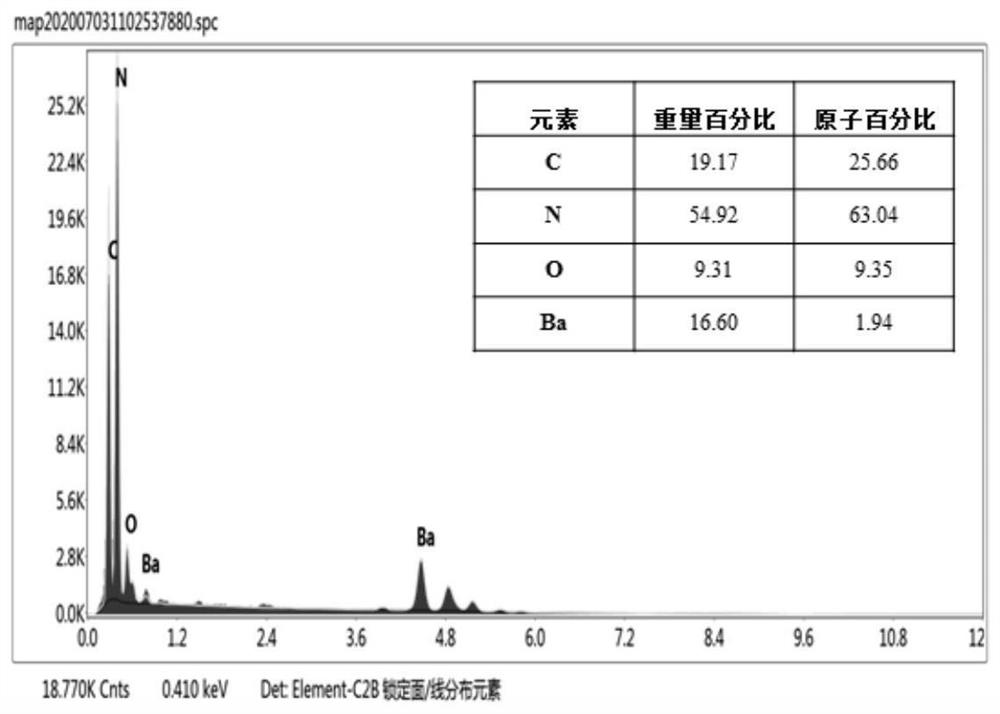

preparation example Construction

[0041] The prepared barium-doped carbon nitride is added to the negative electrode paste of the battery as an additive material, and the preparation method of the negative plate includes the following steps:

[0042] ①Lead powder, short fiber, lignin, humic acid, barium sulfate, barium doped carbon nitride, carbon material according to 100: (0.05-0.5): (0-1.0): (0-1.0): (0-2.0 ): (0.1-1.0): (0-1.0) mass ratio for stirring and mixing;

[0043] ② Add water and sulfuric acid aqueous solution to the mixture obtained in step ① in sequence, and stir well for 1-30 minutes respectively to obtain negative electrode paste, the density of which is 3.5-4.5g / cm 3 ;

[0044] ③Scratch the lead paste evenly on the grid, the thickness of the lead paste is 0.5-10mm, cure at 20-80°C for 1-50h, the relative humidity during the curing process is 90-100%, and then dry at 50-100°C for 0.5 -24h, the relative humidity in the drying process is 0-20%, and the negative plate is obtained.

[0045] In t...

Embodiment 1

[0047] 1000g of lead powder with an oxidation degree of 80%, 3g of barium-doped carbon nitride additive, 0.6g of polyester fiber with a length of 3mm, 2.0g of sodium lignosulfonate, 3.0g of humic acid, 5.0g of fine barium sulfate, Mix 2.0g of carbon material evenly, add 110g of pure water and 85g of it with a density of 1.4g / cm 3 dilute sulfuric acid, stir to obtain the required negative lead paste, and then make the negative plate according to the above method, weld the negative plate with the positive plate and PE diaphragm, and get a 2V12Ah lead-acid single battery after chemical formation. The number of poles is 3 positive poles and 2 negative poles. The battery number is 1#. It is tested for 20hr, 0°C charge acceptance and continuous 17.5% cycle life. See Table 1 for the experimental results.

Embodiment 2

[0049] 1000g of lead powder with an oxidation degree of 80%, 5g of barium-doped carbon nitride additive, 0.6g of polyester fiber with a length of 3mm, 2.0g of sodium lignosulfonate, 3.0g of humic acid, 5.0g of fine barium sulfate, Mix 2.0g of carbon material evenly, add 110g of pure water and 85g of it with a density of 1.4g / cm 3 dilute sulfuric acid, stir to obtain the required negative lead paste, and then make the negative plate according to the above method, weld the negative plate with the positive plate and PE diaphragm, and get a 2V12Ah lead-acid single battery after chemical formation. The number of poles is 3 positive poles and 2 negative poles. The battery number is 2#. It is tested for 20hr, 0°C charge acceptance and continuous 17.5% cycle life. See Table 1 for the experimental results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com