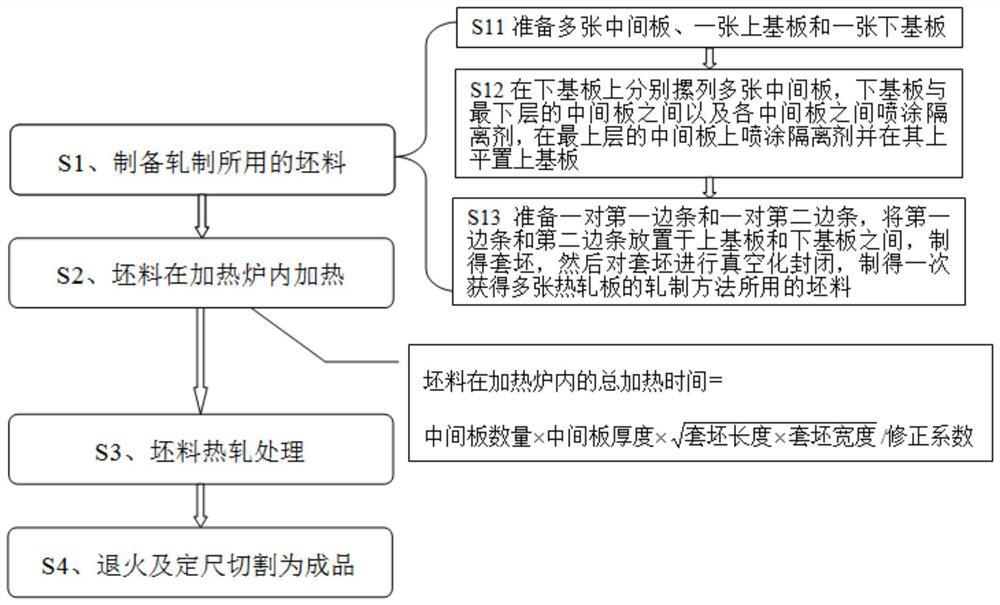

Rolling method for obtaining multiple hot-rolled sheets at one time

A hot-rolled sheet and substrate technology, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of long procurement cycle, complex process flow and high failure rate of high-grade alloy sheets, and achieve high yield and surface quality. Improves the effect of eliminating pickling procedures and short processing cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

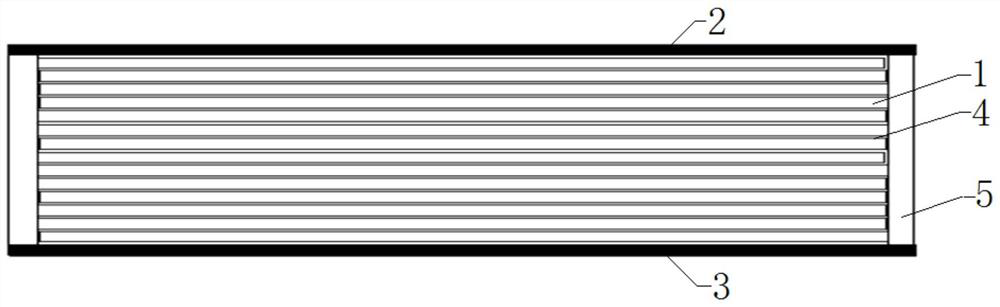

Embodiment 1

[0037]The specifications of the finished hot-rolled plate are required to be 3 mm in thickness x 1950 mm in width x 12000 mm in length, and the number obtained in one rolling is 12 sheets. In order to meet the above production requirements, first prepare 12 pieces of nickel-iron-chromium alloy plates of the grade N08825 whose surface has been pickled or ground for use as intermediate plates. The specifications are thickness 18mm×width 2000mm×length 2100mm; Pickled or ground ordinary carbon steel plates of grade X70MS are used as the upper and lower base plates respectively, and the specifications are thickness 18mm×width 2100mm×length 2200mm; Spray release agent between the intermediate boards and between each intermediate board, spray release agent on the uppermost intermediate board and place the upper substrate on it; prepare four side strips, namely a pair of first side strips and a pair of second side strips Two side strips, the first side strip and the second side strip ...

Embodiment 2

[0040] The specifications of the finished hot-rolled plate are required to be 3mm in thickness x 2100mm in width x 13000mm in length, and the number obtained in one rolling is 12 sheets. In order to meet the above production requirements, first prepare 12 pieces of N06600 nickel-iron-chromium alloy plates whose surfaces have been pickled or ground for use as intermediate plates, and the specifications are thickness 18mm×width 2150mm×length 2230mm; Pickled or ground plain carbon steel plates of grade X70MS are used as the upper and lower base plates respectively, and the specifications are thickness 18mm×width 2250mm×length 2330mm; Spray release agent between the intermediate boards and between each intermediate board, spray release agent on the uppermost intermediate board and place the upper substrate on it; prepare four side strips, namely a pair of first side strips and a pair of second side strips Two side strips, the first side strip and the second side strip are placed b...

Embodiment 3

[0043] The specifications of the finished hot-rolled plate are required to be 4mm in thickness x 2000mm in width x 14000mm in length, and the number obtained in one rolling is 8 sheets. In order to meet the above production requirements, first prepare 8 sheets of 904L super austenitic stainless steel plates whose surfaces have been pickled or ground for use as intermediate plates, with specifications of thickness 24mm×width 2000mm×length 2430mm; The X70 plain carbon steel plates that have been pickled or ground are used as the upper base plate and the lower base plate respectively, and the specifications are thickness 24mm × width 2100mm × length 2530mm; Spray release agent between the intermediate boards and between the intermediate boards, spray release agent on the uppermost intermediate board and place the upper substrate on it; prepare four side strips, namely a pair of first side strips and a pair of For the second side strip, the first side strip and the second side str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com