Production method of clean and pollution-free supersoft tin-plated solder strip

A production method and non-polluting technology, applied in coating, metal material coating process, hot-dip plating process, etc., can solve the problems such as difficult control of yield strength, long production system process, affecting the quality of welding strip, etc., to reduce yield Strength, improvement of surface quality, and reduction of pulling tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

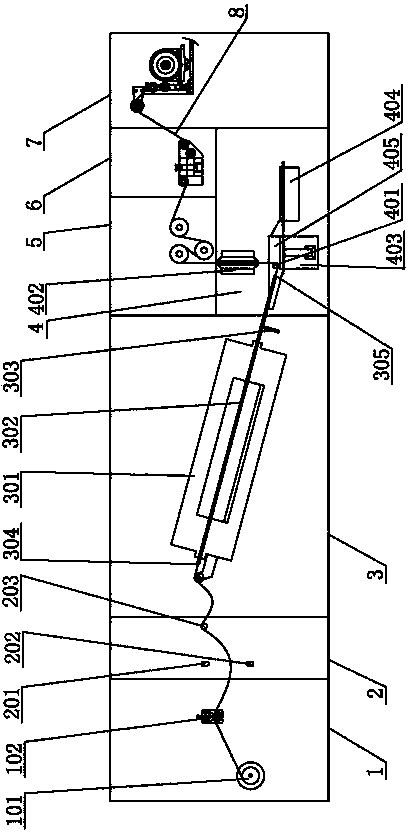

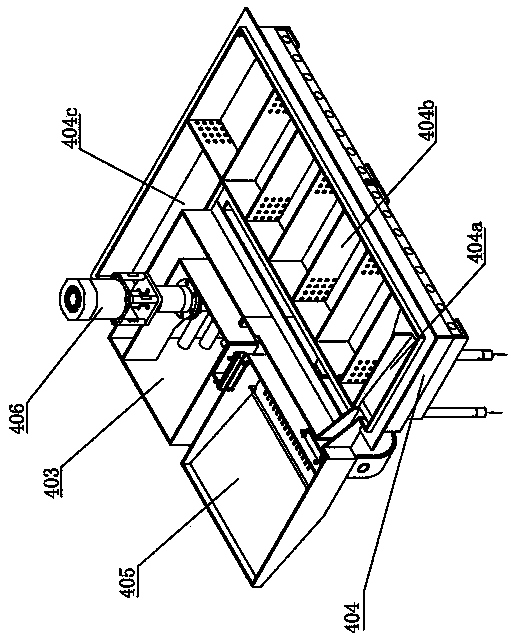

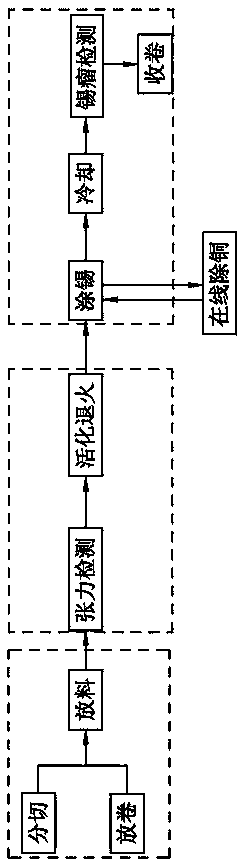

[0026] Such as image 3 Shown, in order to realize the object of the present invention, the production method of the present invention is, be placed on the discharge tray 101 after the hard state copper strip is cut into coils, make the copper strip successively pass through the discharge mechanism 1 of above-mentioned production system, Tension detection mechanism 2, activation annealing furnace 3, tin coating system 4, S roller transmission part 5, tin tumor detection part 6 and receiving system 7.

[0027] Control the rotating speed of the transmission roller in the S roller transmission part 5, the speed of pulling the copper strip into the activation annealing furnace 3 is 1.0m / min, the annealing temperature of the activation annealing furnace is 605 ° C, and the composition of the activation gas that is passed into the activator inlet is A mixed gas of carbon monoxide and argon, wherein the volume content of carbon monoxide is 10%, and the flow rate of the above mixed ga...

Embodiment 2

[0032] The difference from Example 1 is that the rotating speed of the transmission roller in the S roller transmission part is controlled, the speed at which the copper strip is pulled into the activation annealing furnace is 5.0 m / min, and the annealing temperature of the activation annealing furnace is 900 ° C. The composition of the activated gas is a mixed gas of hydrogen and nitrogen, wherein the volume content of hydrogen is 10%, and the flow rate of the above mixed gas is 50L / min.

[0033] The composition of the tin liquid in the tin coating system is 63Sn37Pb, the temperature of the tin liquid in the spout of the tin furnace is 270°C, the set temperature of the cooling tank is 235°C, the set temperature of the heat preservation tank is 205°C, and the set temperature of the heating tank is 270°C ℃.

[0034] The finished product welding strip detection result of embodiment 2 is as follows table:

[0035] project Example 1 Tensile strength Rm (Mpa) 167.1...

Embodiment 3

[0037] The difference from Example 1 is that the rotating speed of the transmission roller in the S roller transmission part is controlled, the speed at which the copper strip is pulled into the activation annealing furnace is 4m / min, and the annealing temperature of the activation annealing furnace is 800°C. The composition of the activated gas is a mixed gas of water vapor and nitrogen, wherein the volume content of water vapor is 20%, and the flow rate of the above mixed gas is 30L / min.

[0038] The composition of the tin liquid in the tin coating system is 62Sn36Pb2Ag, the temperature of the tin liquid in the spout of the tin furnace is 260°C, the set temperature of the cooling tank is 230°C, the set temperature of the heat preservation tank is 200°C, and the set temperature of the heating tank is 260°C ℃.

[0039] The finished product welding strip detection result of embodiment 3 is as follows table:

[0040] project Example 1 Tensile strength Rm (Mpa) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com