Ear belt production device of mask machine

A production device and earband technology, which is applied in the direction of clothing, sewing tools, textile material cutting, etc., can solve the problems of wasting a lot of time and difficulty in further improving work efficiency, so as to save connection time and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

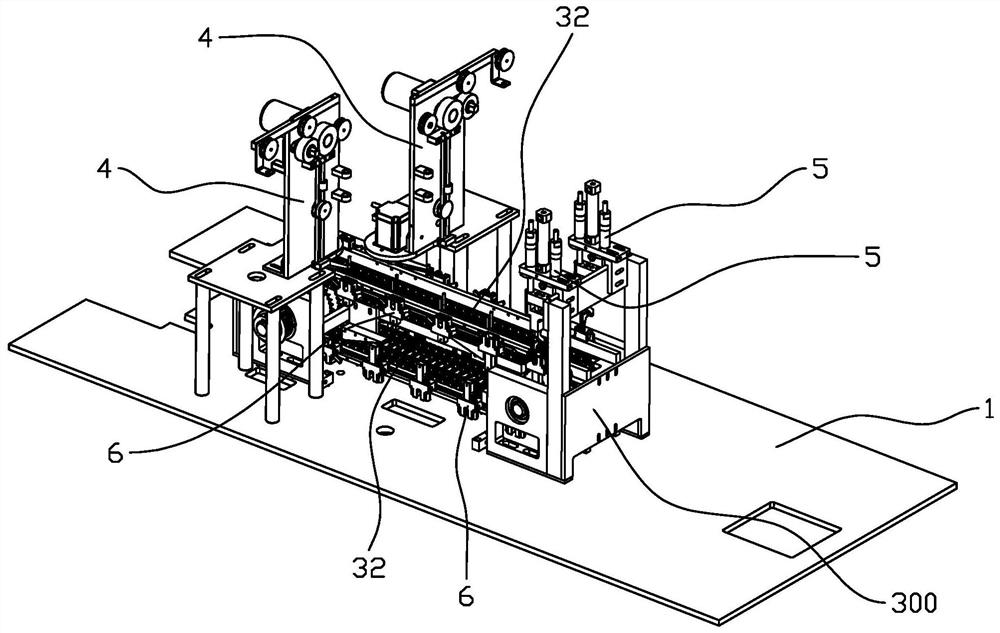

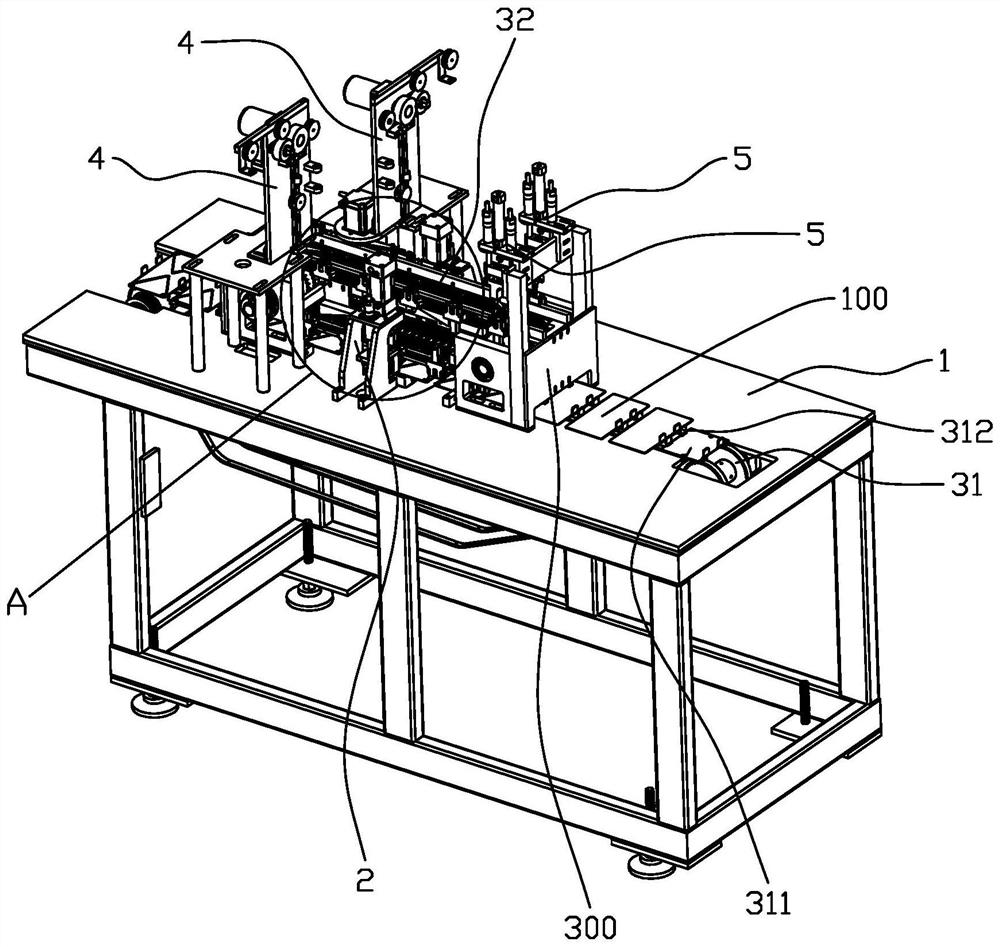

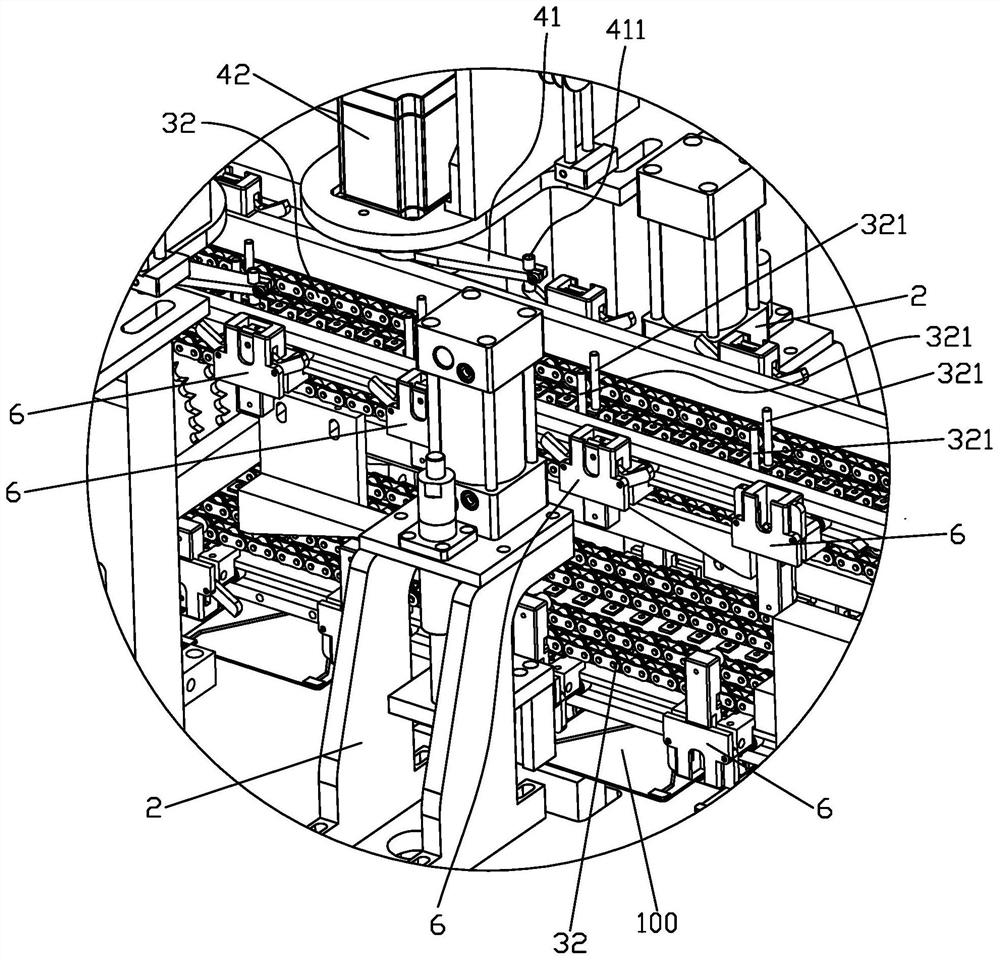

[0034] refer to Figure 1 to Figure 12 , a mask machine, comprising a workbench 1, a welding device 2 is arranged on the workbench 1, and a mask body conveying line 31, an ear belt conveying line support 300, a wiring mechanism 4 and a shearing mechanism 5 are also arranged on the workbench 1 When the mask body conveying line 31 works, the mask body 100 is transported to the working area of the welding device 2 one by one; the earband conveying line support 300 is provided with an earband conveying line 32, and how many intervals are arranged on one side of the earband conveying line 32? A thread clamping mechanism 6 that moves with it, each thread clamping mechanism 6 includes two thread clamping devices, and the two thread clamping devices are arranged at intervals so that the two can respectively clamp t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com