Full-automatic powder weighing and forming equipment

A molding equipment, fully automatic technology, applied in automatic feeding/discharging weighing equipment, detailed information of weighing equipment, weighing, etc., can solve problems such as low efficiency, low safety performance, and large use limitations , to achieve the effect of improving production efficiency, product weight and size uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

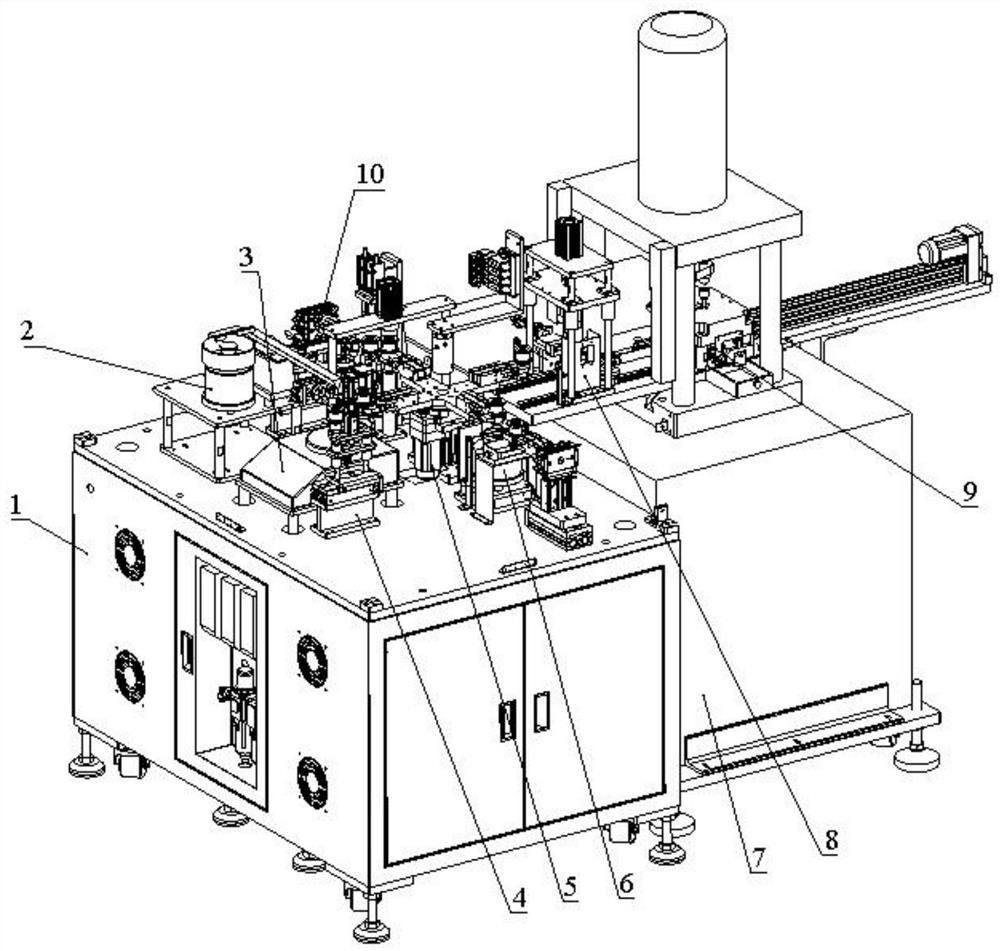

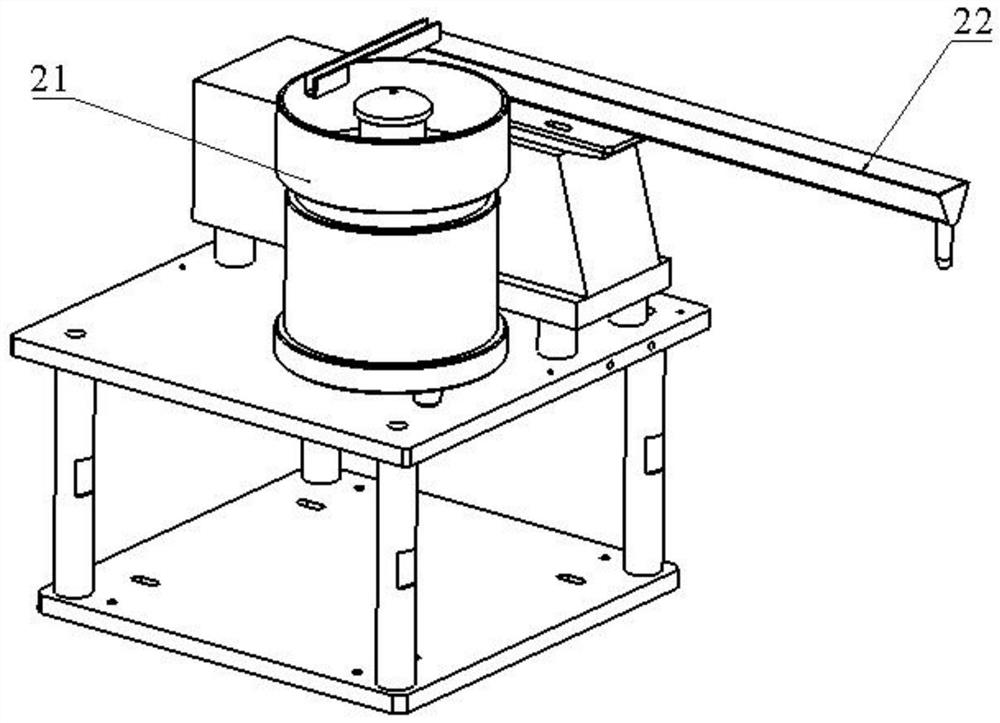

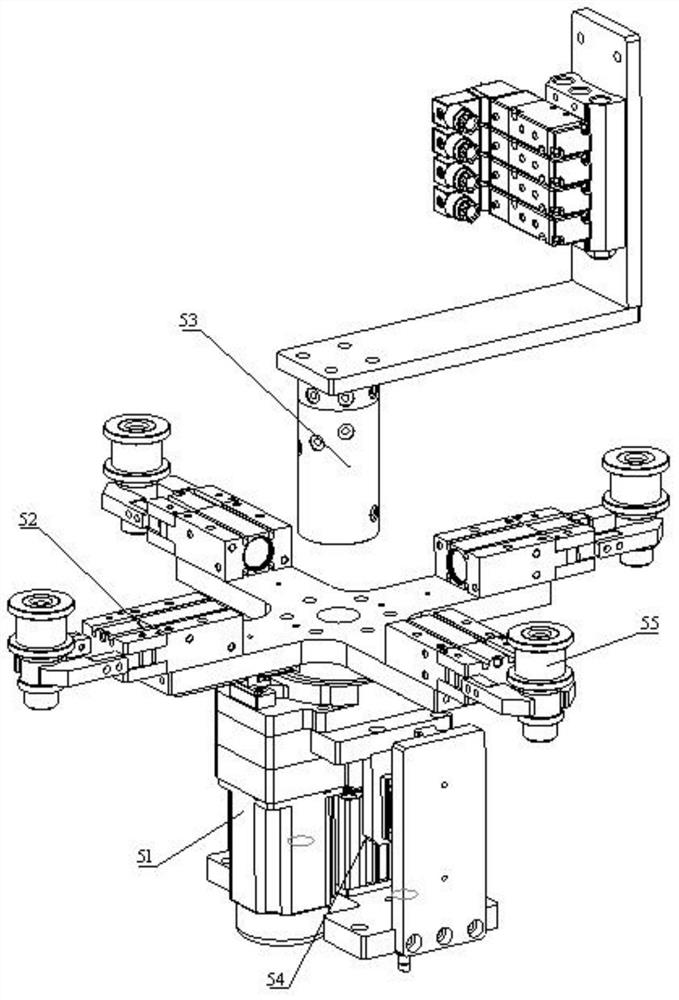

[0022] combined with figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , attached Figure 5 , attached Figure 6 And attached Figure 7 , a fully automatic powder weighing and forming equipment, including a body 1 and a hydraulic press 7, a powder feeding mechanism 2 is fixed on the body 1, and a fixed device is fixed on the body 1 and below the powder feeding mechanism 2 There is a precision electronic scale mechanism 3, on the body 1 and in front of the precision electronic scale mechanism 3, a jig traverse mechanism 4 is provided, on the body 1 and on one side of the precision electronic scale mechanism 3, a Rotary transport mechanism 5, on the body 1 and in front of the rotary transport mechanism 5, there is a powder shaking and super-heavy and ultra-light powder cleaning mechanism 6, on the body 1 and behind the rotary transpor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com