A probe and method for measuring the pretightening force of transmission tower bolts with temperature compensation

A bolt pre-tightening force, transmission tower technology, applied in force/torque/power measuring instrument, measuring torque/torsion force during tightening, measuring device, etc., can solve problems such as difficult to meet the technical requirements of bolt health status monitoring, and achieve loading and unloading Convenient, Measuring Accurate Results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

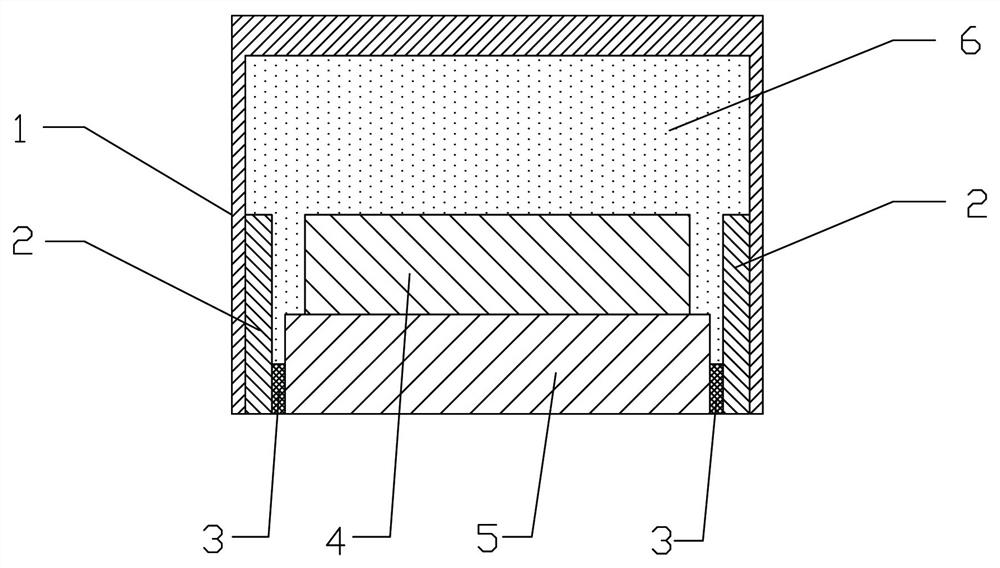

[0033] see figure 1 , a temperature-compensated power transmission tower bolt pre-tightening force measuring probe, comprising an aluminum alloy cylindrical shell 1 and a fixing ring 2 arranged in the shell 1, a temperature sensor 3, a cylindrical longitudinal wave ultrasonic piezoelectric ceramic chip 4, a cylindrical Shaped transverse wave ultrasonic piezoelectric ceramic chip 5, shell 1 protects the internal sensor; cylindrical transverse wave ultrasonic piezoelectric ceramic chip 5 is set in the middle of the shell 1 and fits with the bolt section, the transverse wave signal is 5-8MHz, and the cylindrical longitudinal wave ultrasonic pressure The electric ceramic chip 4 is arranged above the cylindrical transverse wave ultrasonic piezoelectric ceramic chip 5, and the longitudinal wave signal is 2-5 MHz;

[0034] The fixing ring 2 is set on the inner wall of the shell 1 and fixed with the bolts. The fixing ring 2 is a ring-shaped adsorption magnet, which is attracted to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com