Optical cable rapid butt joint device

A docking device and fast technology, applied in the directions of light guides, optics, optical components, etc., can solve the problems of high scrap rate, low optical fiber splicing efficiency, and failure to reach the splicing process, saving time, facilitating optical cable splicing, and aligning speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

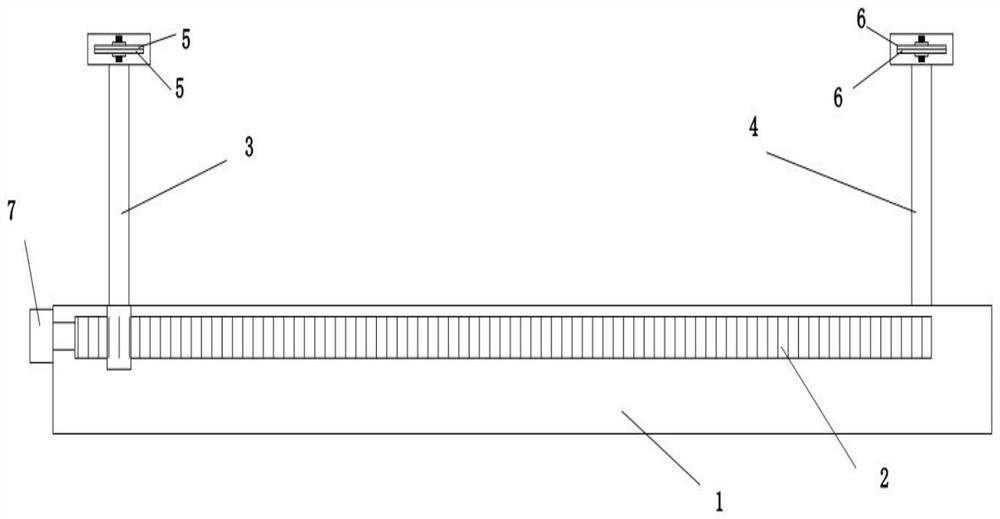

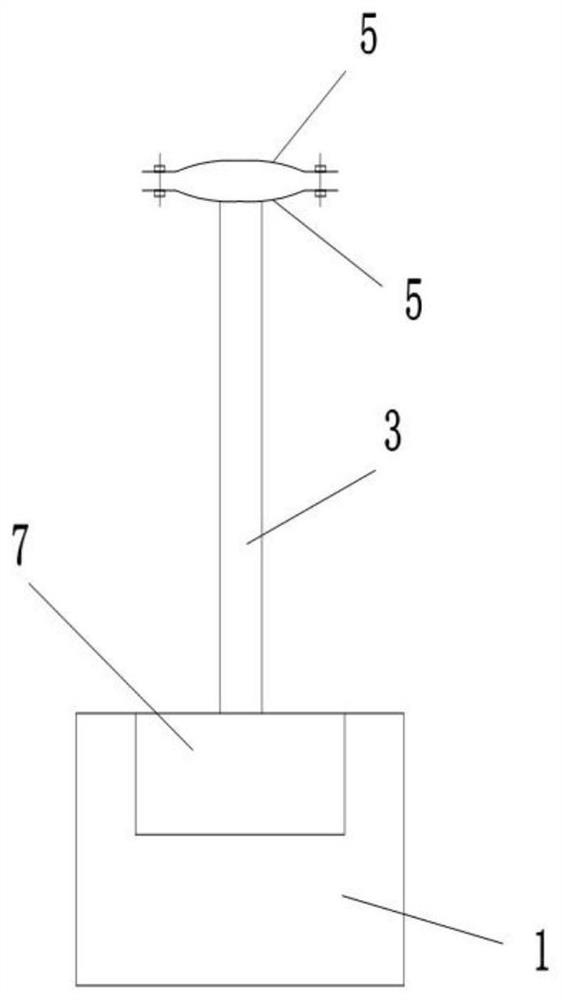

[0016] The present invention is an optical cable fast docking device, such as Figure 1-2 As shown, including the base 1, the base 1 is provided with a screw 2, the screw nut of the screw 2 is fixed with a support rod a3, the top of the support rod a3 is fixed with a clamping assembly a, and the base 1 is also fixed with a support rod b4 , the support rod b4 is close to the end of the screw of the lead screw 2, the top of the support rod b4 is fixed with the clamping component b, the screw 2 drives the clamping component a close to or away from the clamping component b, the clamping component a and the clamping component b are located at the same high.

[0017] The clamping assembly a includes two clamping plates a5 buckled up and down. The clamping plates a5 have radians. The radians of the two clamping plates a5 match the middle to form a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com