Wafer concentric normalizing device

A wafer and regular technology, which is applied in the field of wafer concentric regularization devices, can solve the problems of inconvenient wafer handling, inconvenience in taking and placing, influence of centering accuracy, inaccurate positioning, etc., so as to improve production efficiency and processing quality. , The effect of improving working conditions and accurate positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

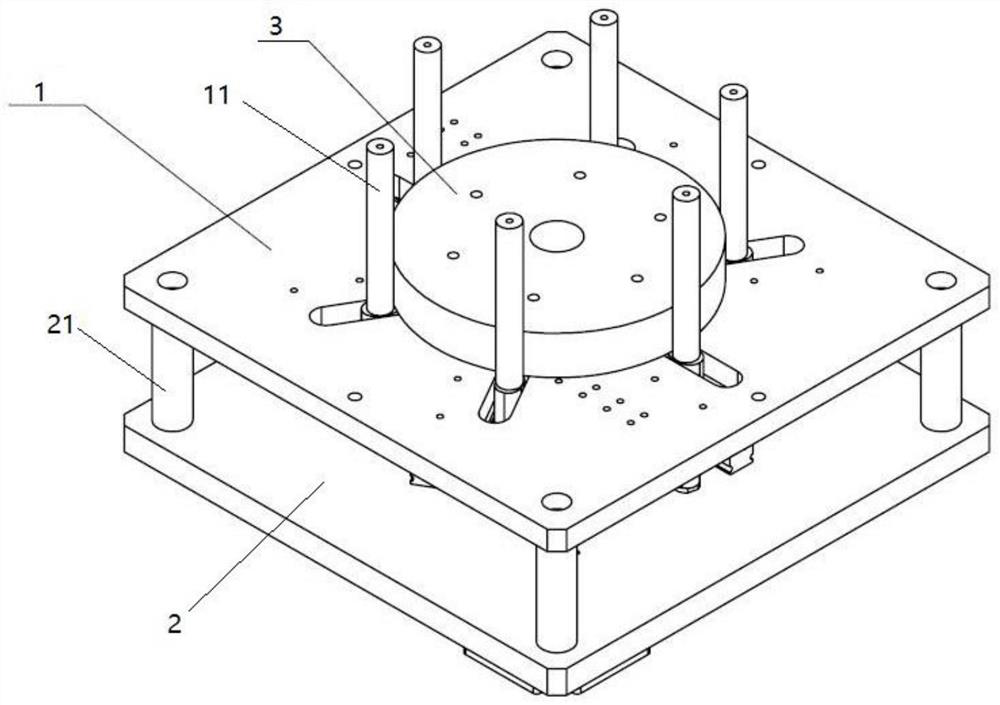

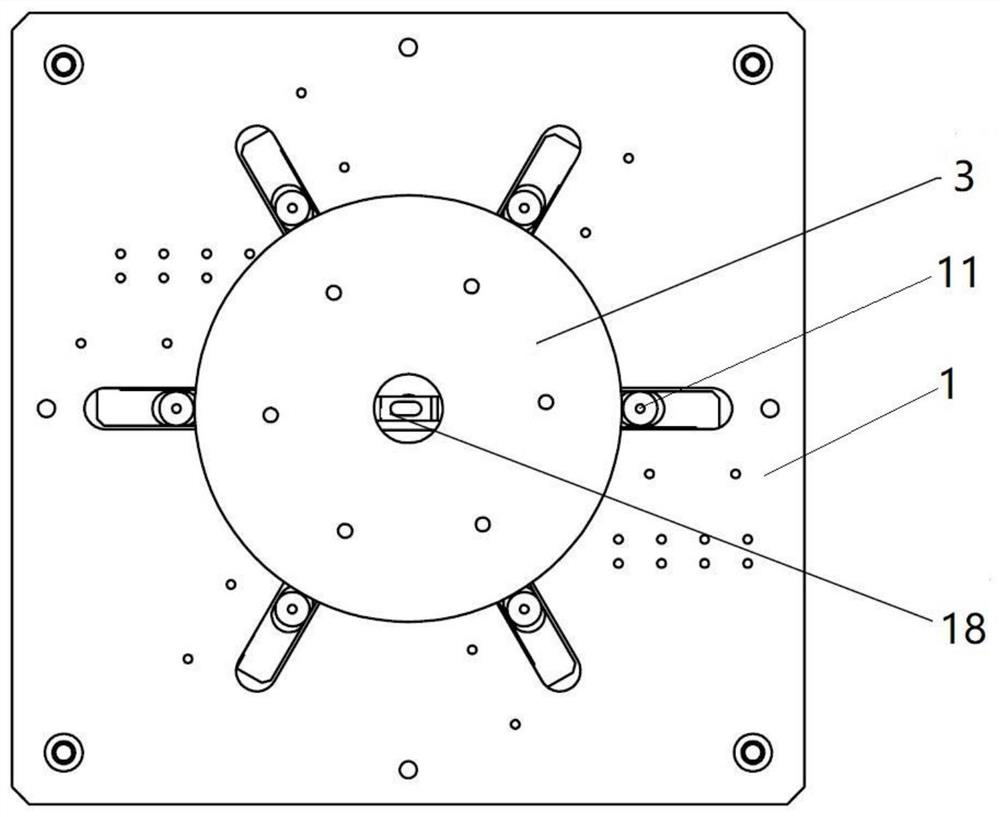

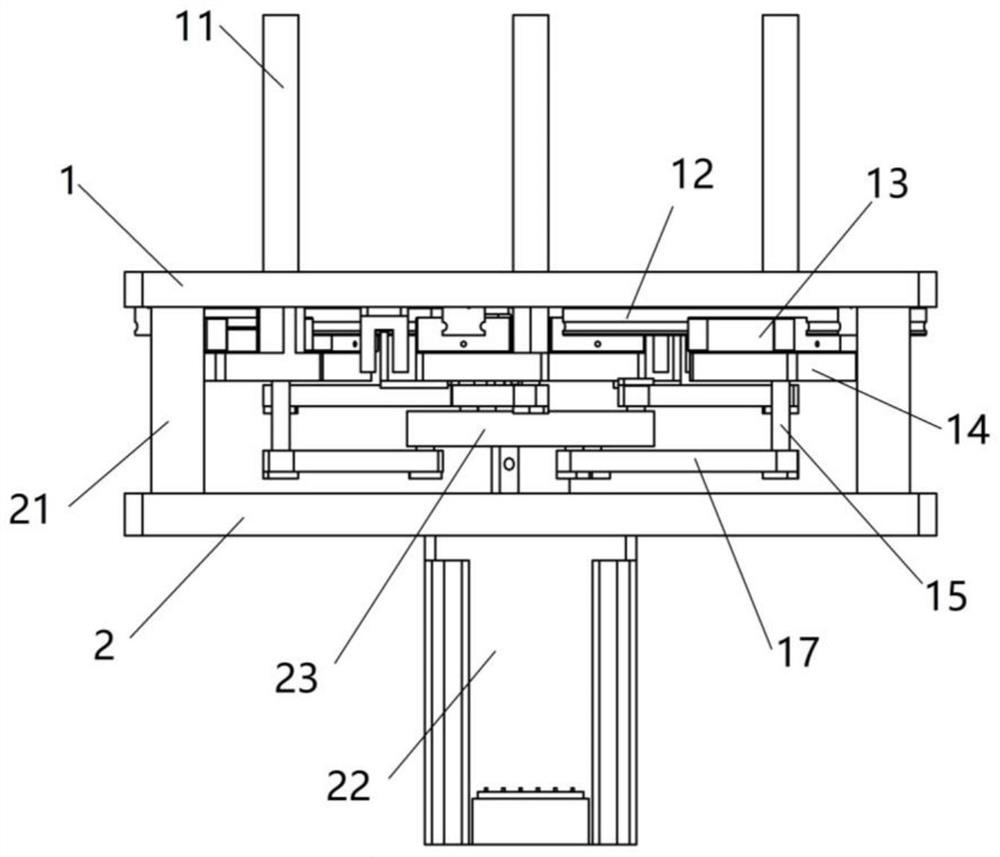

[0019] Such as figure 1 Only Figure 4 As shown, a wafer concentric regularization mechanism includes a mounting plate 1, a fixed plate 2 and a regular mechanism; the mounting plate 1 is mounted on the fixed plate 2 through a support shaft 21; One side is provided with a linear guide rail 12; the linear guide rail 12 is provided with a slider 13; the bottom of the fixed plate 2 is provided with a stepping motor 22; the center of the mounting plate 1 is provided with a circular hole, and the There is an inductive switch 18; the mounting plate 1 is also provided with a limit device that limits the regularization mechanism.

[0020] The regularizing mechanism includes a regularizing shaft 11, a chain bar 17 and a turntable 23; the bottom of the regularizing shaft 11 is connected with a slider connector 14; the slider connector 14 is fixedly connected to the slider 13; the chain bar 17 One end of it is connected with the slider connector 14 through the long positioning pin 15, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com