Solder ball size screening device and method

A screening device and solder ball technology, applied in sorting and other directions, can solve the problems of high labor cost, unsatisfactory screen ball, huge hardware investment, etc., and achieve the effect of low labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

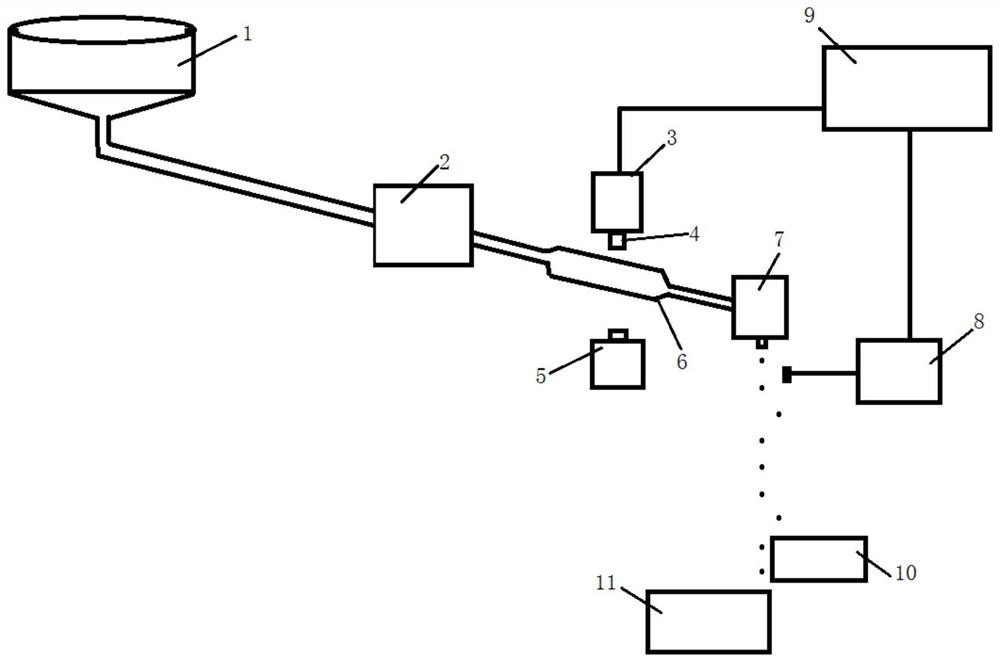

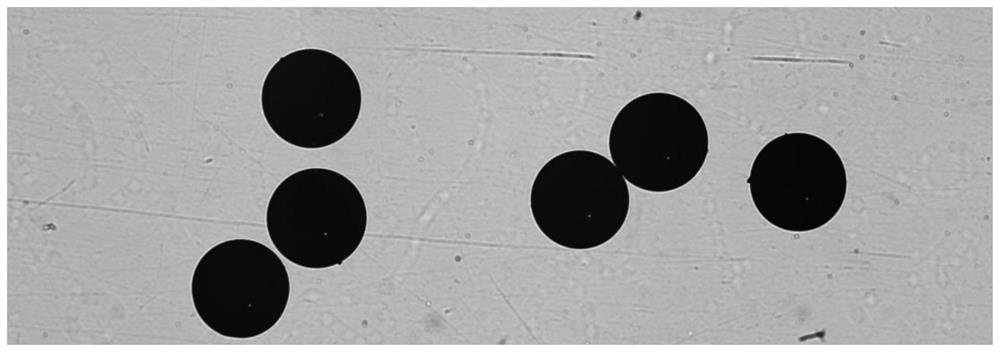

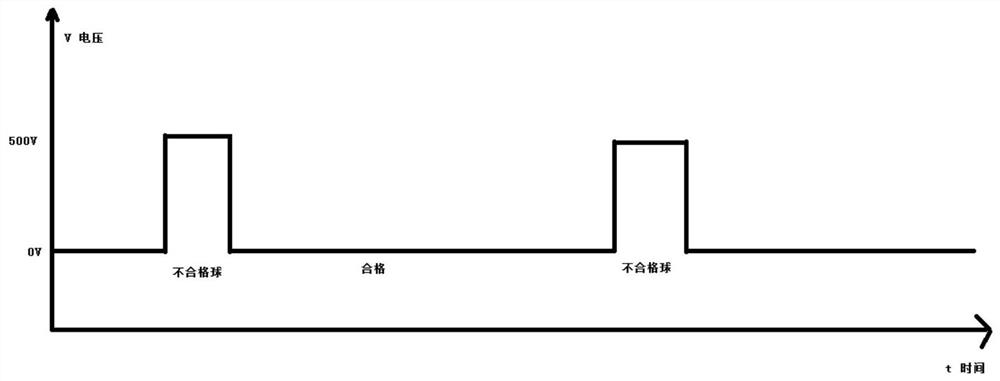

[0021] combine figure 1 , a tin ball size screening device, including a feeder 1, the feeder 1 is in the shape of a funnel, the feeder 1 is connected to a ball rolling path adjuster 2 through a pipe, and the diameter of the ball rolling path adjuster 2 is the diameter of the pipe. 1.5 times, a vibration motor is installed at the entrance of the ball rolling path adjuster 2, the output end of the ball rolling path adjuster 2 is connected to the optical glass track 6, the end of the optical glass track 6 is connected to the positive electrostatic generator 7, and the bottom of the positive electrostatic generator 6 is connected. A qualified ball container 11 is provided; an industrial camera 3 is provided directly above the optical glass track 6, a telecentric lens 4 is provided on the industrial camera 3, and a telece...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap