Separation system for continuous casting

A technology of continuous casting and slab casting, which is applied in the direction of furnace, furnace type, heat treatment equipment, etc. It can solve the problems of high requirements for equipment automation control, difficulty in meeting, unfavorable hooking up of slab under hooking machine, etc., so as to avoid impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

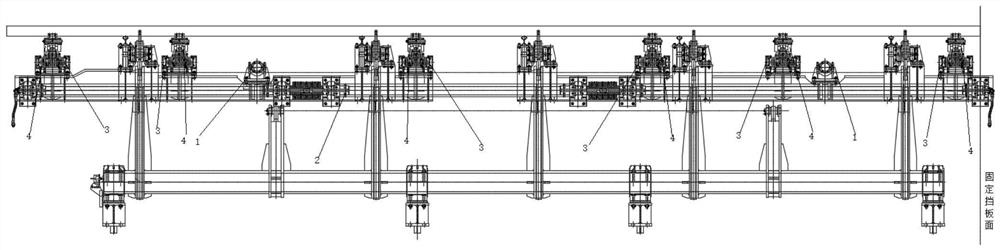

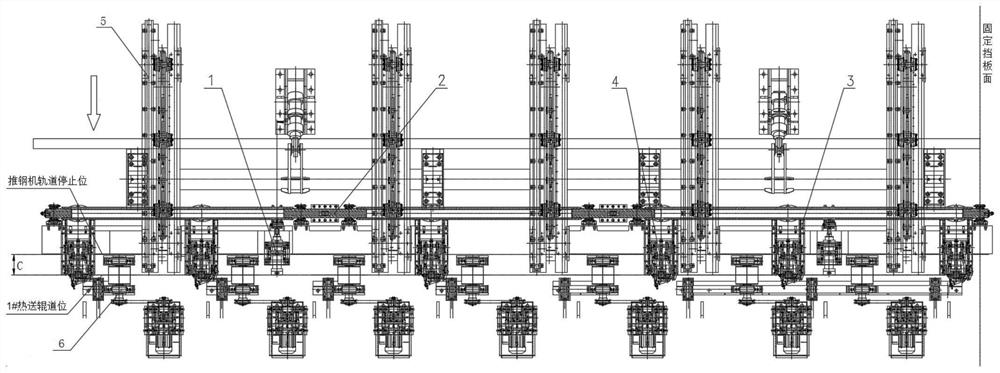

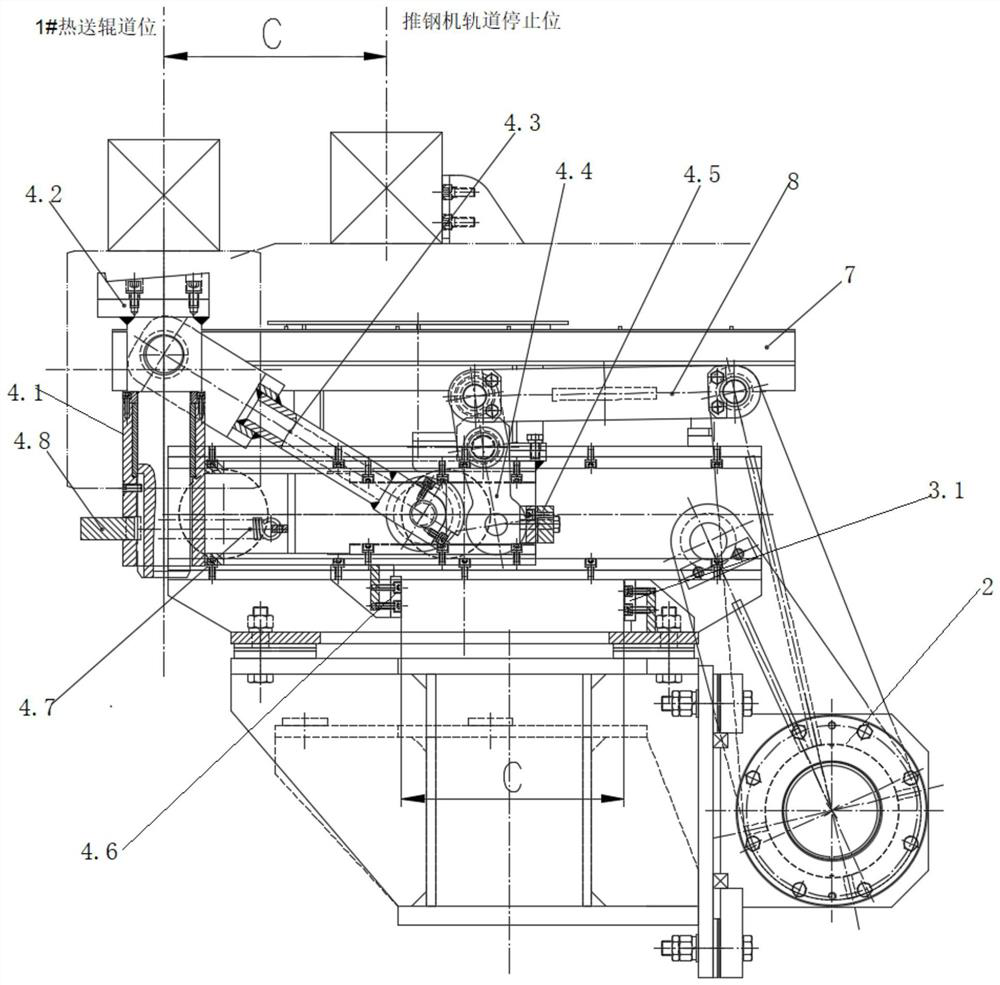

[0034] like Figure 1 to Figure 9 As shown, a steel splitting system for continuous casting includes a synchronous shaft 2, a hydraulic cylinder 1, a guide rail frame 3 and a billet trolley 4, the synchronous shaft 2 is parallel to the longitudinal direction of the billet, and the hydraulic cylinder 1 and guide rail frame 3 are perpendicular to the billet Longitudinal and along the longitudinal direction of the billet, it is distributed in the remaining space of the pusher rail beam 5, 1# hot-feeding roller table 6 and hook claws of the steel hooking machine. The supporting blank trolley 4 is fitted on the guide rail of the guide rail frame 3 through the wheels 4.13 without falling out. 3.5, the blank support trolley 4 is equipped with a lifting rod 4.2 for supporting the casting slab, all the hydraulic cylinders 1 drive all the blank support trolleys 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com