A kind of adobe adobe pressing device for building

A technology for construction and brick blanks, which is applied to supply devices, unloading devices, manufacturing tools, etc., can solve the problems of easy crushing, cumbersome operation, time-consuming and laborious, and achieve the effect of preventing crushing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

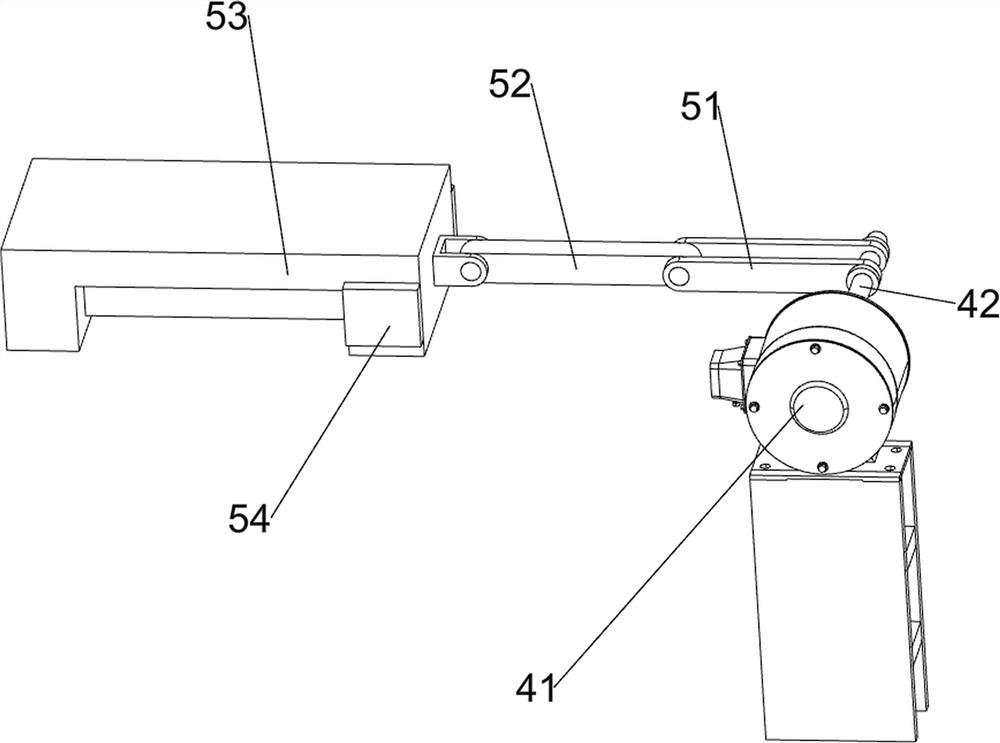

[0025] A kind of adobe adobe pressing device for building, such as Figure 1 to Figure 4 As shown, it includes a base plate 1, a support frame 2, a limit plate 3, a driving mechanism 4, an extrusion mechanism 5, a feeding mechanism 6, a push-pull mechanism 7 and a feeding funnel 9, and the support frame 2 is connected in the middle of the top of the bottom plate 1. The top of the support frame 2 is connected to the limiting plate 3, the top of the bottom plate 1 is equipped with a driving mechanism 4, the limiting plate 3 is respectively equipped with an extrusion mechanism 5 and a push-pull mechanism 7, the extrusion mechanism 5 is connected to the driving mechanism 4, and the limiting plate 3. A feeding funnel 9 is connected to the top, and a feeding mechanism 6 is installed on the feeding funnel 9, and the feeding mechanism 6 is connected with the driving mechanism 4 through transmission.

[0026] The driving mechanism 4 includes a low-speed motor 41 and a power shaft 42. T...

Embodiment 2

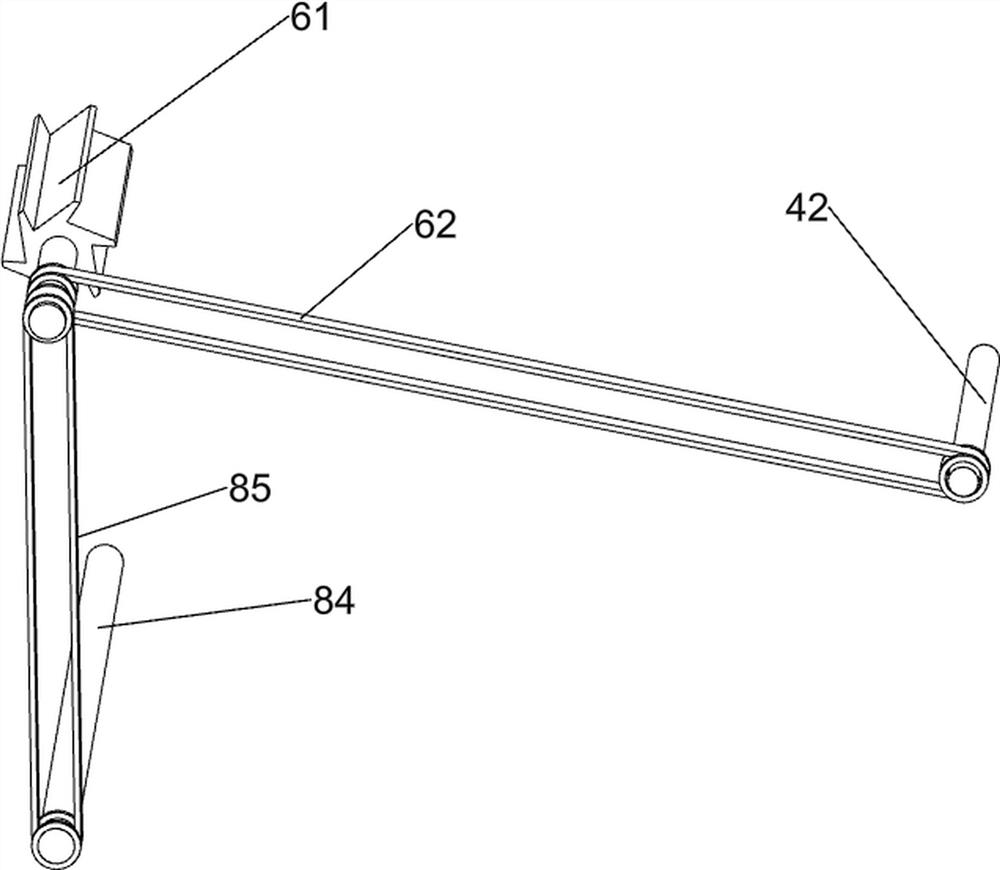

[0032] On the basis of Example 1, such as image 3 and Figure 5 As shown, a conveying mechanism 8 is also included, and the conveying mechanism 8 includes a conveyor belt group 81, a push block 82, an inclined slide plate 83, a transmission shaft 84 and a second flat belt group 85, and the rear side of the bottom plate 1 is rotatably connected with a conveyor belt group 81 , the conveyor belt of the conveyor belt group 81 is connected with a plurality of push blocks 82, the top rear side of the base plate 1 is connected with an inclined slide plate 83, the inclined slide plate 83 is located on the left side of the conveyor belt group 81, and the conveyor belt group 81 is connected with a transmission shaft 84, and the transmission shaft 84 is connected to the conveyor belt group 81. A second flat belt set 85 is connected between the six-tooth blanking wheels 61 .

[0033] When the adobe brick moves backward to a suitable position, the adobe adobe falls on the inclined slide ...

Embodiment 3

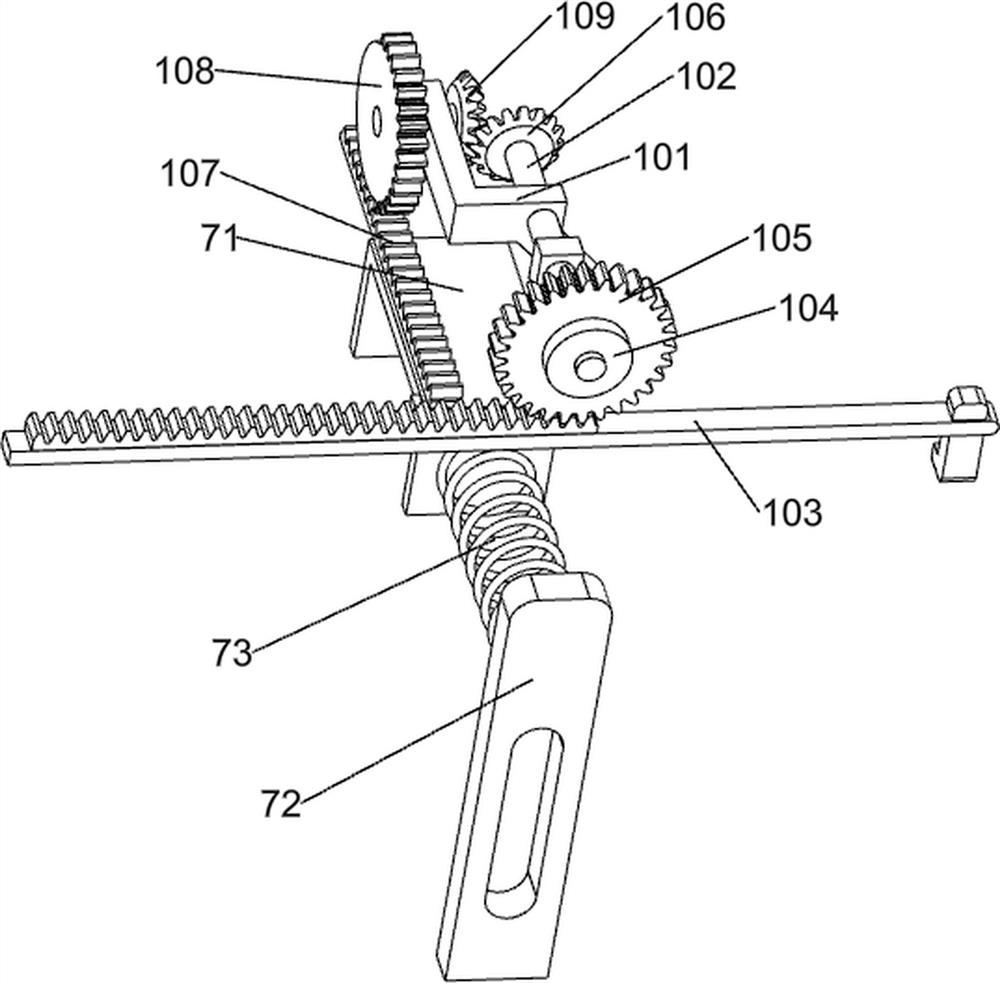

[0035] On the basis of Example 2, such as Figure 4As shown, a transmission mechanism 10 is also included, and the transmission mechanism 10 includes a fixed block 101, a power transmission rod 102, a rack frame 103, a one-way clutch 104, a transmission gear 105, a first bevel gear 106, a rack block 107, The sector gear 108 and the second bevel gear 109, the top of the limiting plate 3 is connected with a fixed block 101, the fixed block 101 is located on the left side of the feeding funnel 9, and the front of the fixed block 101 is connected with a power transmission rod 102 in a rotating manner. The front side of the side slider 54 is connected with a rack frame 103, the front end of the power transmission rod 102 is connected with a one-way clutch 104, and the one-way clutch 104 is connected with a transmission gear 105, the transmission gear 105 meshes with the rack frame 103, and the power transmission rod The rear end of 102 is connected with the first bevel gear 106, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com