Filling device for pesticide intermediate processing

A technology for filling devices and intermediates, which is applied in the field of filling devices for processing pesticide intermediates, can solve problems such as increased production costs, low degree of freedom, unfavorable processing, etc., and achieves simple and easy operation of the device, improved filling quality, The effect of improving filling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

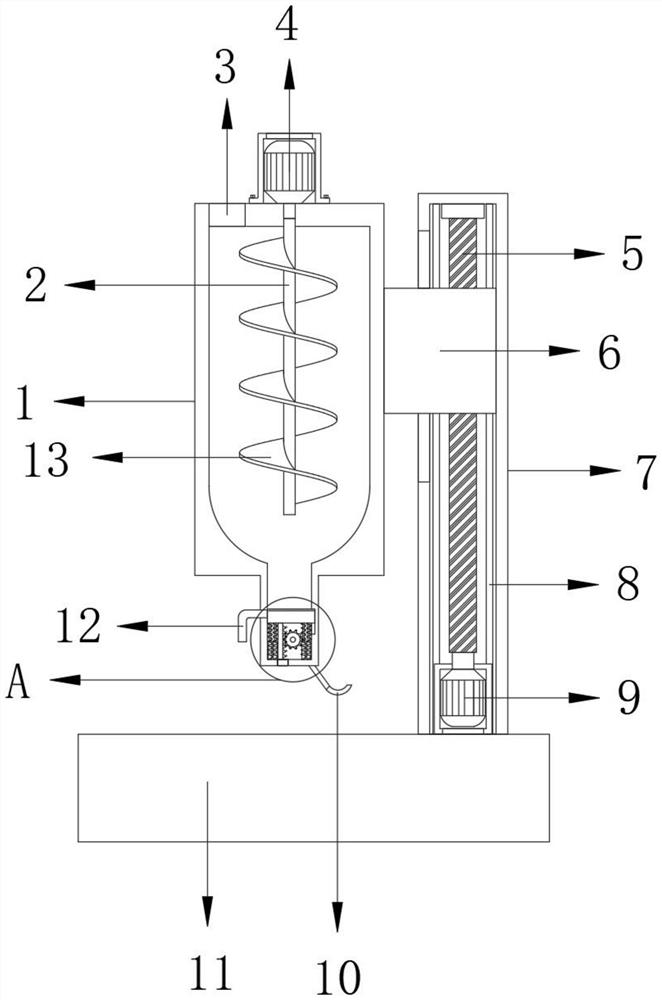

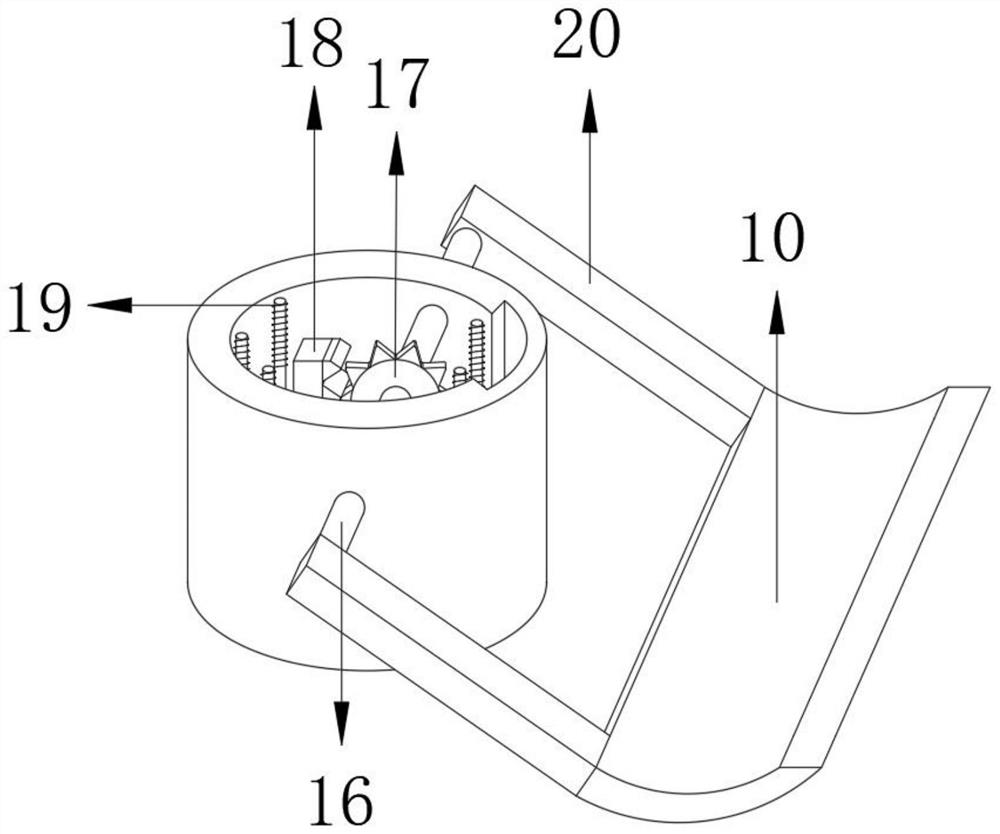

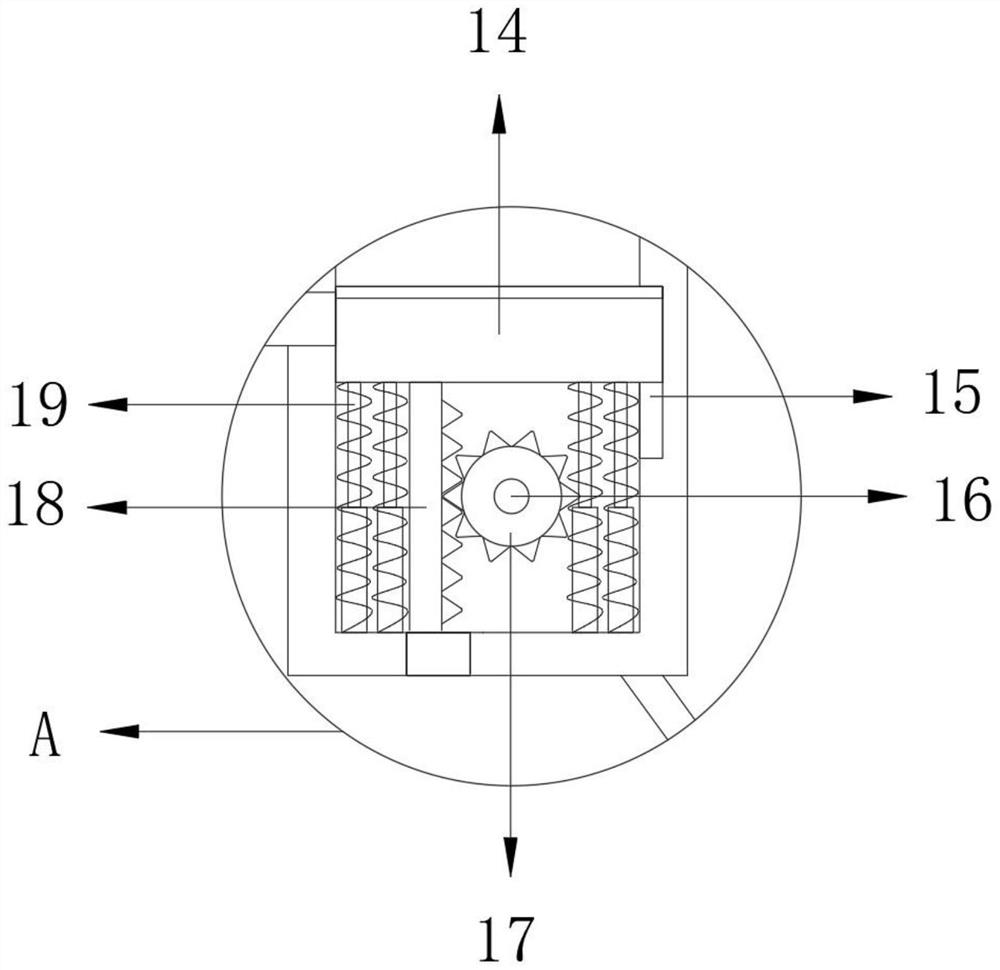

[0027] refer to Figure 1-3 , a filling device for processing pesticide intermediates, comprising a lifting box 7, the bottom of the inner wall of the lifting box 7 is connected with a second motor 9 through bolts, and one end of the output shaft of the second motor 9 is connected with a screw rod 5 through a bolt, and the screw rod 5 The other end is connected to the top of the inner wall of the lifting box 7 through a bearing, and a filling box 1 is arranged on one side of the lifting box 7. The top end of the filling box 1 is provided with a feed port 3, and the bottom of the inner wall of the filling box 1 passes through Bolts are connected with tooth plates 18, and the bottom of the inner wall of the filling box 1 is connected with a plurality of telescopic rods 19 by bolts. The bottom of one side of the inner wall of the filling box 1 has a limit groove 15, and the tops of the telescopic rods 19 are connected by bolts. A piston 14, and one side of the piston 14 is in con...

Embodiment 2

[0035] refer to Figure 4 , a filling device for processing pesticide intermediates. Compared with Embodiment 1, this embodiment has a chute 24 at one end of the top of the console 11, and a fixed groove 22 at the bottom of one side of the console 11. The fixed groove One side of the inner wall of 22 is connected with electric push rod 21 by bolt, and the output shaft one end of electric push rod 21 is connected with the first drive frame by bolt, and the other end of the first drive frame is connected with support frame 23 by bolt, and the support frame 23 The other end is connected with a second transmission frame by bolts, and the other end of the second transmission frame is connected with a holding pan 25 by bolts, and the bottom of the holding pan 25 is in contact with the inner wall bottom of the chute 24 .

[0036] Working principle: when in use, put the filling container into the holding tray 25, and the output end of the electric push rod 21 moves toward the inside o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com