Large-angle belt turning auxiliary device

An auxiliary device and a large-angle technology, which is applied in the direction of transportation and packaging, conveyor objects, conveyors, etc., can solve the problems that the equipment cannot achieve life, cannot meet production needs, and difficult to debug, so as to achieve stable work, simple debugging, and easy use. long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

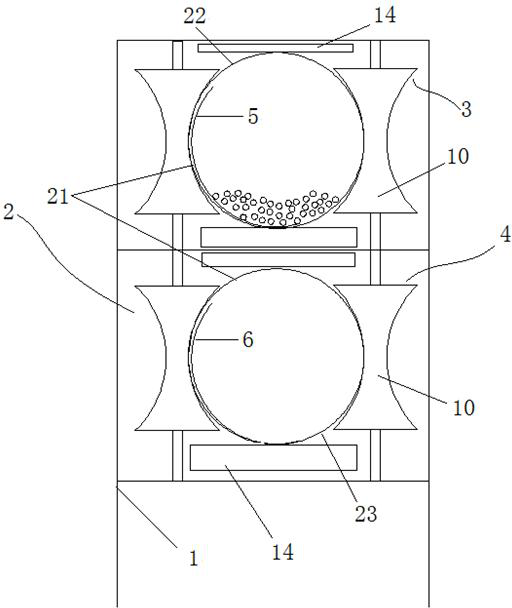

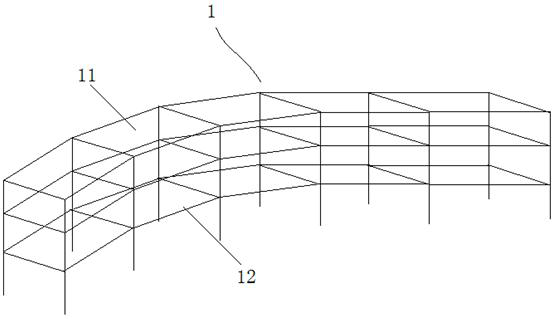

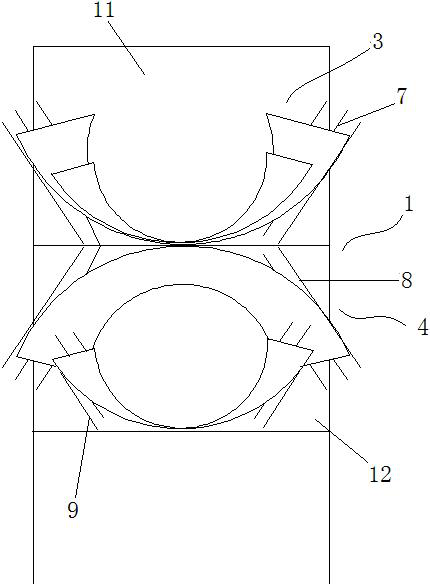

[0023] like figure 1 As shown, a large-angle belt turning auxiliary device includes a turning frame 1 and an auxiliary belt mechanism 2. The auxiliary belt mechanism 2 is installed on the turning frame 1. The auxiliary belt mechanism 2 includes an auxiliary belt 21 and is sleeved on both sides of the auxiliary belt. The belt roller at the end, as well as the upper auxiliary assembly 3 and the lower auxiliary assembly 4, the upper auxiliary assembly 3 gathers the upper auxiliary belt 22 into an upward hollow open circle, circle or similar circle, wraps the upper belt 5 of the belt conveyor upwards, and the lower The auxiliary assembly 4 gathers the lower auxiliary belt 23 into a downward hollow open circle, circle or similar circle in cross section, and wraps up the lower belt 6 of the belt conveyor.

[0024] The package proposed above is a full package or a partial package. When the upper auxiliary belt or the lower auxiliary belt is a hollow circle or a quasi-circle, it is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com