A plate material handling mechanism

A technology of handling mechanism and handling machinery, applied in the direction of conveyor, transportation and packaging, conveyor objects, etc., can solve the problem of low efficiency of feeding steps, and achieve clear mechanism movement principle, make up for low degree of automation, and simple and efficient mechanism. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

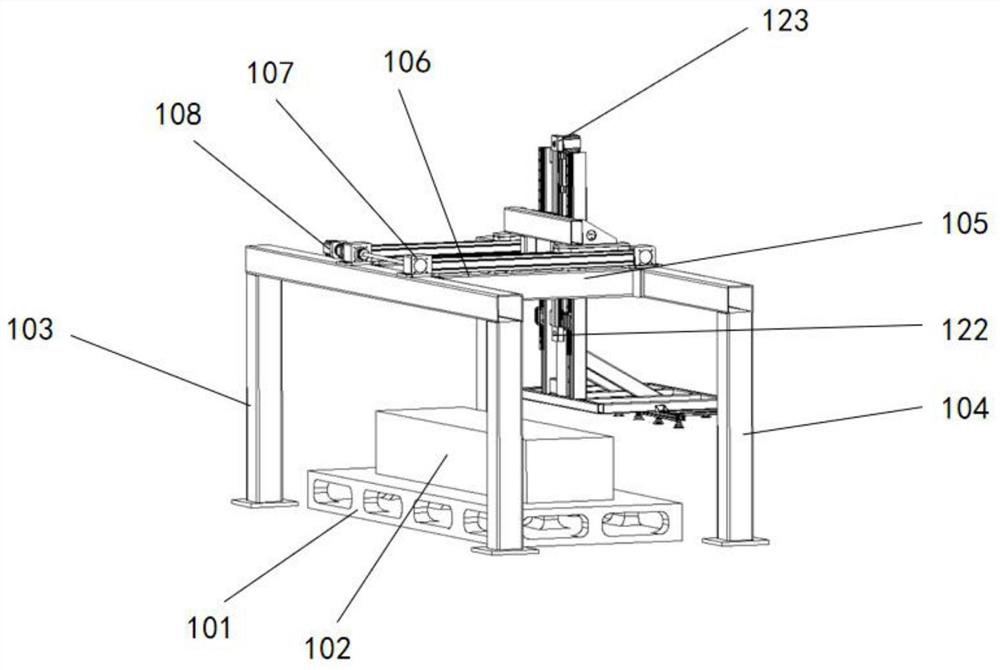

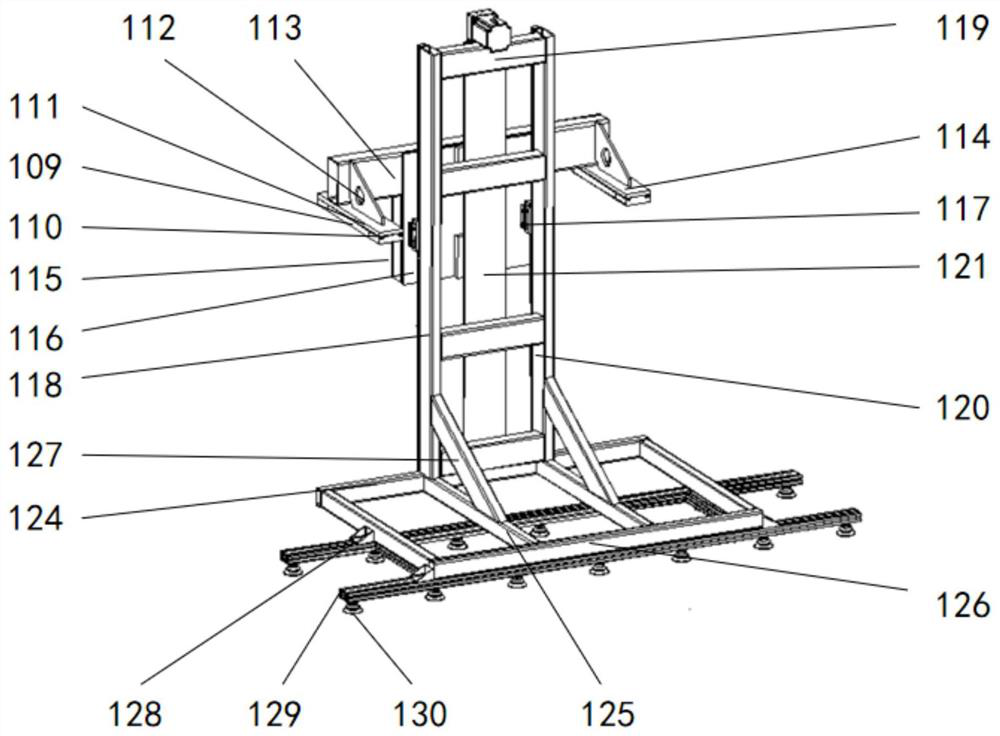

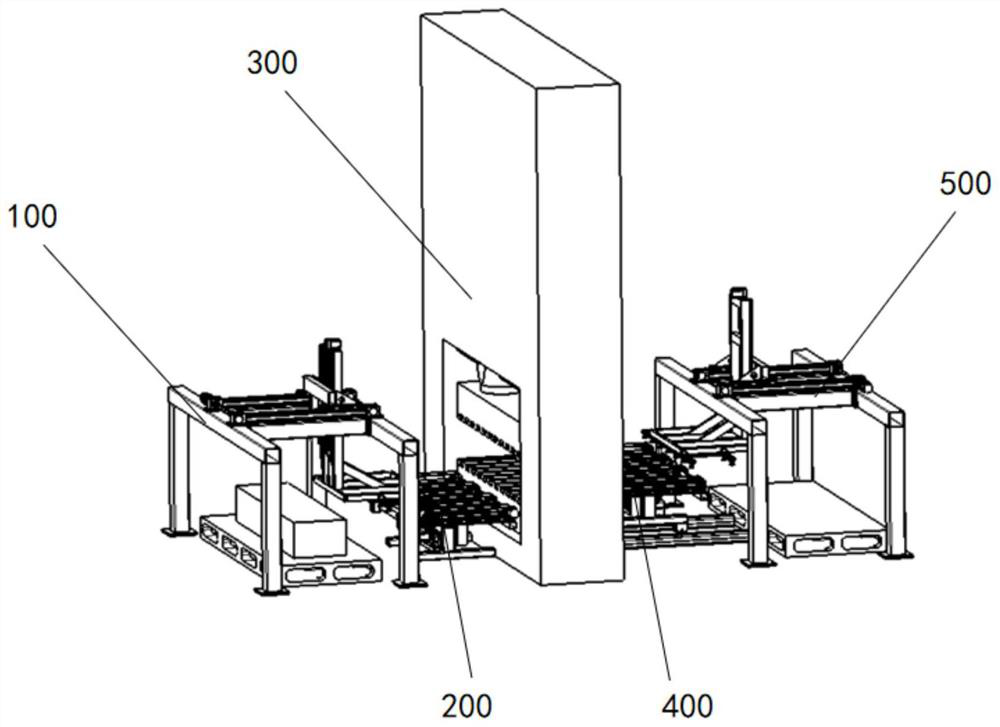

[0018] like Figure 1-2As shown, a plate material loading and handling mechanism, the material loading and handling module 100 is composed of a material loading platform 101, a plate material 102, a first material loading frame 103, a second material loading frame 104, a material loading beam 105, and a material loading frame. Connecting plate 106, first mobile module 107, first mobile module drive motor 108, material loading and transporting mechanical arm slider 109, material loading and transporting mechanical arm slider moving block 110, material loading and transporting mechanical arm first support plate 111, Loading and handling manipulator support stiffener plate 112, material handling manipulator support connecting plate 113, material handling manipulator second support plate 114, material handling manipulator fixed beam 115, material handling manipulator connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com