A kind of carboxylic acid compound and its preparation method and application

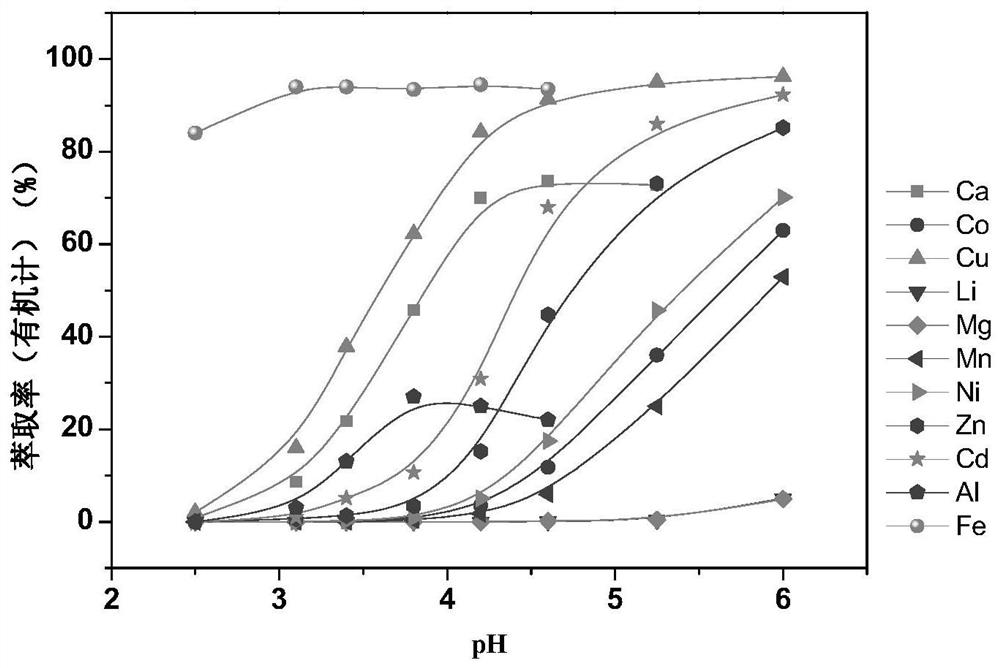

A technology of compounds and carboxylic acids, which is applied in the field of carboxylic acid compounds and their preparation and application, can solve the problems of simultaneous extraction of nickel, cobalt and manganese, complex operation procedures, high acidity of stripping, etc., and achieve high saturation capacity and stable extraction process , the effect of low acidity in stripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

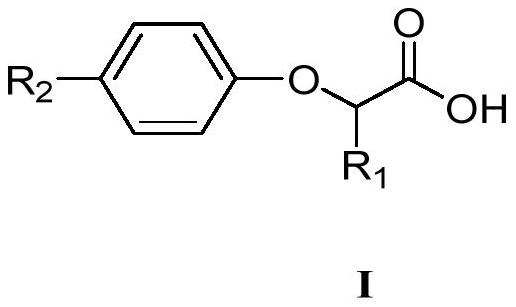

Method used

Image

Examples

Embodiment 1

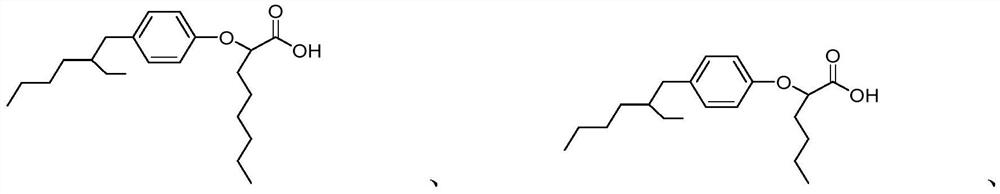

[0082]

[0083] Add 84.6g isooctylphenol, 250mL tetrahydrofuran (THF), 8.8g sodium particles to the three-necked flask, react at 60-70℃ for 6h, a large amount of white solids are formed, and a small amount of sodium particles remain; at 60℃, dropwise add 40mL containing 8mol / L THF solution of 2-bromooctanoic acid and continue to react at 60°C for 4h; after cooling, after rotary evaporation to remove THF, add 200mL of water and 200mL of ethyl acetate (EA) to the concentrated solution, shake the layers, and take the water layer; water; The layer was acidified with hydrochloric acid to pH ≈ 1, extracted with ethyl acetate, the organic phase was washed twice with water, and spin-dried to obtain 86 g of a light yellow product, namely compound BC195. 1 H NMR (400MHz, CDCl 3 )δ10.20(1H,br.);7.32(2H,t);6.68(2H,d);4.84-4.81(1H,m);2.6(2H,m);2.20-2.08(2H,m); 1.66-1.56 (5H, m); 1.46-1.38 (12H, m); 0.99 (3H, t, J=7.3, CH3); 0.93 (3H, t, J=7.3, CH3); 0.90 (3H, t, J=7.3, CH3); 13 CNMR ...

Embodiment 2

[0085]

[0086] Add 48.4g of isooctylphenol, 225mL of tetrahydrofuran (THF), 8.8g of 60% sodium hydride (dispersed in mineral oil) into the three-necked flask, and react at 60~70℃ for 6h, a large amount of white solids are formed, and a small amount of sodium particles remain; 20mL of 10mol / L 2-bromohexanoic acid in THF solution was added dropwise at 60°C and the reaction was continued at 60°C for 4h; after cooling, the THF was removed by rotary evaporation, 200mL of water and 200mL of ethyl acetate (EA) were added to the concentrated solution, The layers were shaken and separated, and the water layer was taken; the water layer was acidified with hydrochloric acid to pH ≈ 1, extracted with ethyl acetate, the organic phase was washed twice with water, and spin-dried to obtain 52 g of a light yellow product, namely compound BC196. 1 H NMR (400MHz, CDCl 3 )δ10.10(1H,br.);7.30(2H,t);6.66(2H,d);4.83-4.81(1H,m);2.57(2H,m);2.17-2.04(2H,m); 1.62-1.53 (3H, m); 1.42-1.34 (10H, m);...

Embodiment 3

[0088]

[0089] Add 54.2g n-nonylphenol, 200mL tetrahydrofuran (THF), 5.7g sodium particles to the three-necked flask, react at 60-70℃ for 6h, a large amount of white solids are formed, and a small amount of sodium particles remain; at 60℃, 20mL are added dropwise respectively 10mol / L THF solution of 2-bromohexanoic acid and continue to react at 60°C for 4h; after cooling, after rotary evaporation of THF, add 200mL of water and 200mL of ethyl acetate (EA) to the concentrated solution, shake the layers, and take the water layer; The aqueous layer was acidified with hydrochloric acid to pH≈1, extracted with ethyl acetate, the organic phase was washed twice with water, and spin-dried to obtain the target compound, namely compound BC191.

[0090] Compound BC191 1 H NMR (400MHz, CDCl 3 )δ9.20(1H,br.);7.31(2H,t);6.67(2H,d);4.83(1H,m);2.5(2H,m);2.21(2H,m);1.63(4H, m); 1.46-1.38 (14H, m); 0.93 (3H, t, J=7.3, CH3); 0.90 (3H, t, J=7.3, CH3); MS[M-H] - :334.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com