Construction method for solving pile foundation over-filling and sediment in karst region

A construction method and slag sedimentation technology, which can be used in basic structure engineering, sheet pile walls, buildings, etc., can solve the problems of pile bottom sediment, increased construction trouble, overfilling and other problems, and achieve construction quality and construction period guarantee, construction quality and construction. The effect of cycle optimization and high pile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

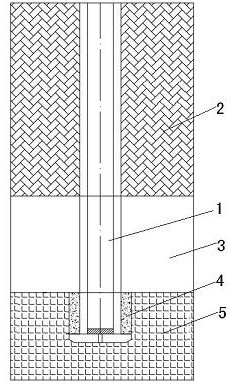

[0025] Attached below Figure 1-2 And embodiment the present invention is described further:

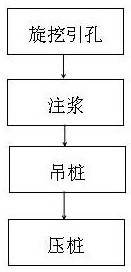

[0026] A construction method to solve over-filling and sedimentation of pile foundations in karst areas. The prefabricated pipe piles used in the construction are prestressed high-strength concrete pipe piles. The specific construction steps are as follows: ①Rotary excavation lead hole: use rotary excavation pile machine or submerged hole Hammer pilot hole for rotary digging, the diameter of the pilot hole is 20~100mm larger than the diameter of the prefabricated pipe pile. It is determined according to the length of the pile. If the pile grows longer, the pilot hole takes the larger value. The sediment at the bottom of the hole should be cleaned, and the hole position error is ±5.00cm , The verticality deviation of the lead hole should not be greater than 0.5%.

[0027] ② After the introduction hole, inject grout into the introduction hole, and use a catheter to pour an appropriate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com