Intelligent steel support axial force adjusting method based on bp neural network

A bp neural network and intelligent adjustment technology, applied in neural learning methods, biological neural network models, neural architectures, etc., can solve problems such as no relevant standards, lag, and large differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manner of the present invention will be described in more detail below with reference to schematic diagrams. The advantages and features of the present invention will be more apparent from the following description. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

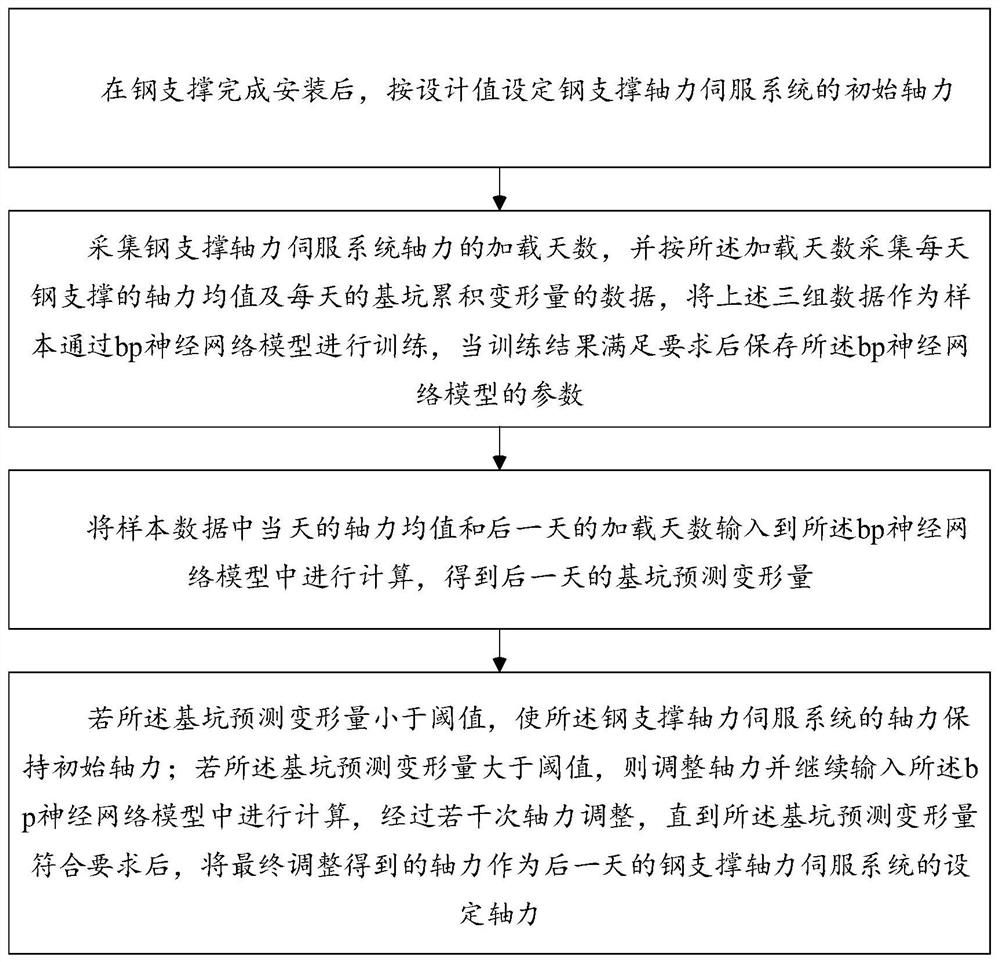

[0030] Such as figure 1 As shown, this embodiment provides a method for intelligent adjustment of steel support axial force based on bp neural network, including:

[0031] Step S1: After the steel support is installed, set the initial axial force of the steel support axial force servo system according to the design value;

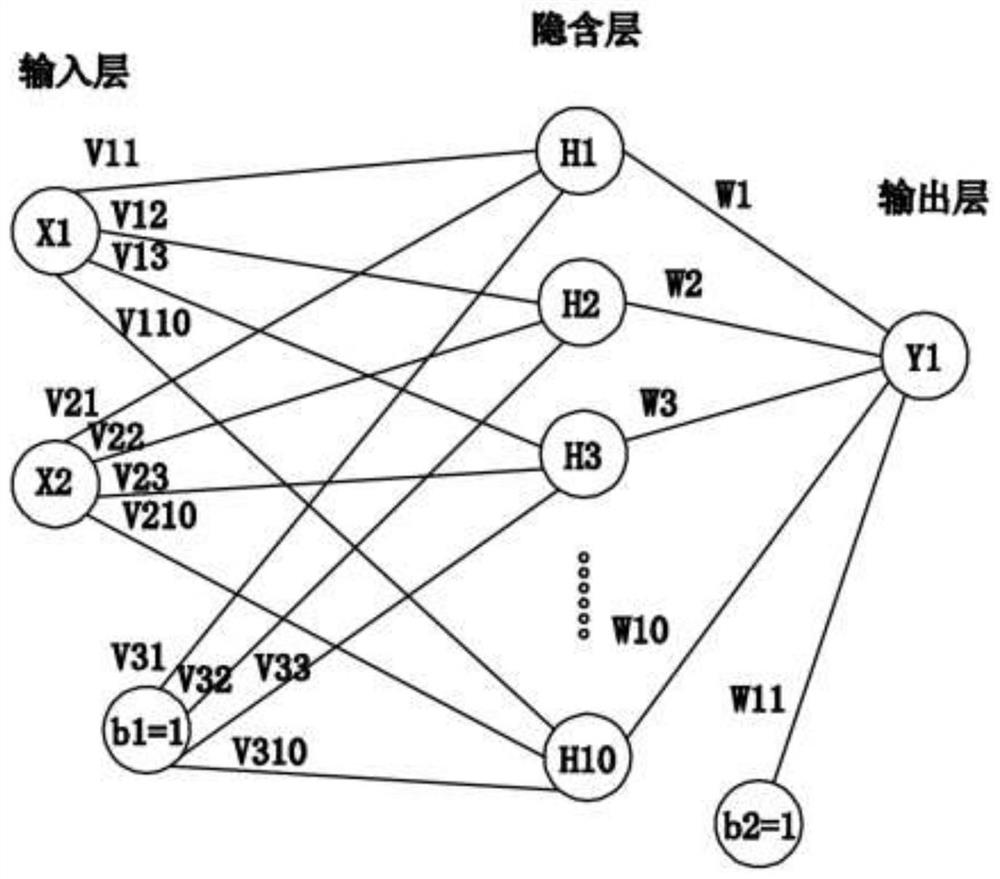

[0032] Step S2: Collect the loading days of the axial force of the steel support axial force servo system, and collect the data of the average value of the axial force of the steel support and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com