Precise aligning measurement auxiliary system for complex steel structure overall lifting before in-place

A technology of overall lifting and auxiliary system, applied in the direction of lifting device, measuring instrument, measuring device, etc., can solve the problems of large spatial vertical coordinate difference, large manual measurement error, large difference in lifting force, etc., to reduce labor costs. Activity costs and the effect of manual measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is further illustrated below by specific examples.

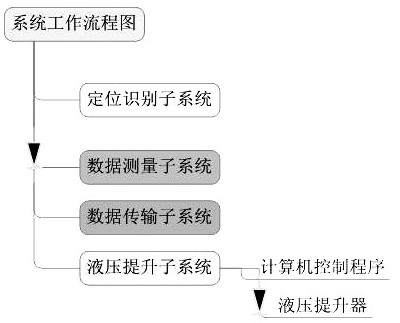

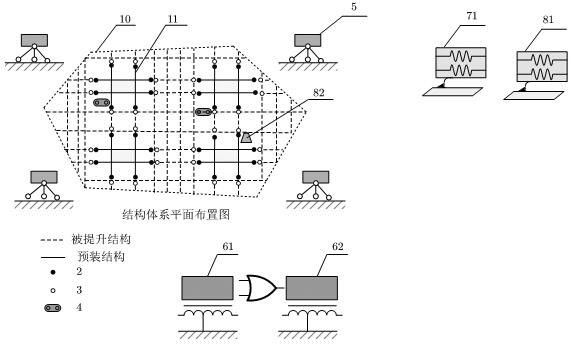

[0033] like figure 1 As shown in Fig. 1 , a precise alignment measurement auxiliary system for the overall lifting of a complex steel structure, including a positioning identification subsystem, a data measurement subsystem, a data transmission subsystem, a calculation and analysis subsystem, and a hydraulic lifting subsystem;

[0034] The positioning identification subsystem includes reflective stickers respectively arranged at the interface of the pre-installed structure and the lifted structure;

[0035] The data measurement subsystem includes a measurement network composed of multiple automatic total stations, which are used to monitor points and return data to the data transmission subsystem;

[0036] The data transmission subsystem consists of a data acquisition instrument and a data transmitter. The data acquisition instrument collects the point coordinate data measured and returned by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com