Slide way inclined shaft variable high-pressure plunger pump

A technology of high-pressure plunger pumps and slideways, which is applied in the direction of pumps, multi-cylinder pumps, liquid displacement machinery, etc., can solve the problems of affecting the overall efficiency of the pump, heavy plunger design, rigidity requirement dependence, etc., and achieve the overall structure setting Reasonable, prevent vibration and string movement, improve the effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

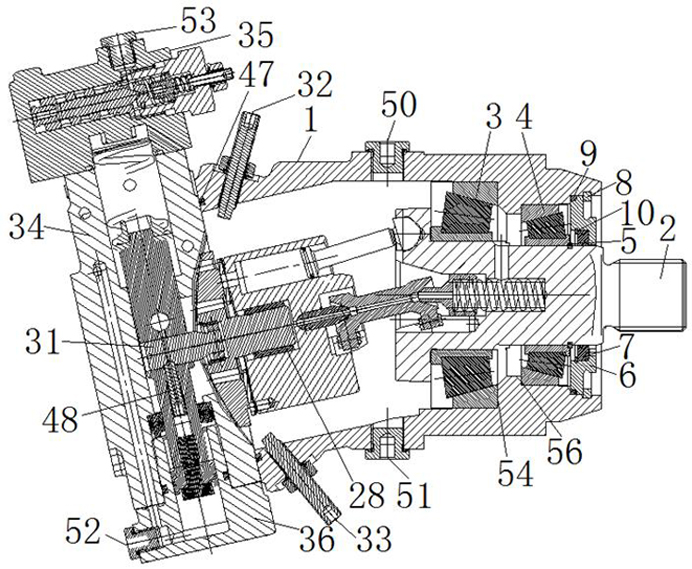

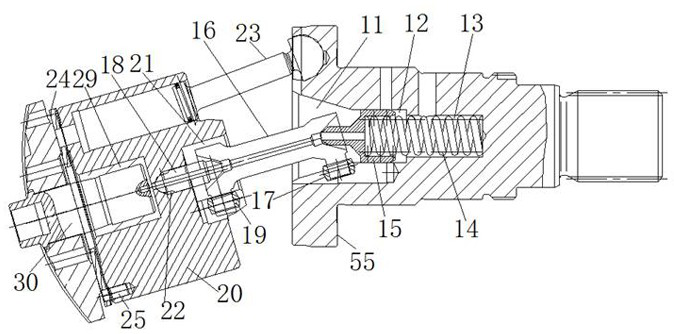

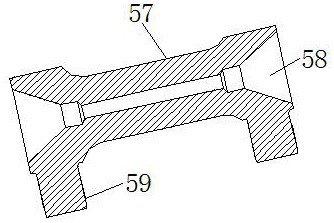

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5As shown in the present invention, a slideway oblique axis variable high-pressure plunger pump includes a bearing housing 1, a spline shaft 2 is arranged inside the bearing housing 1, and a spline shaft 2 is outside the spline shaft 2. Set two tapered thrust bearings, which are divided into tapered thrust bearing I3 and tapered thrust bearing II4, the outer diameter of the tapered thrust bearing I3 is larger than the outer diameter of the tapered thrust bearing II4, the tapered thrust bearing Fixed in the bearing housing 1, one end of the tapered thrust bearing I3 is placed on the step I54 in the bearing housing 1, and the other end is placed on the step II55 of the spline shaft 2. The tapered thrust bearing II4 One end leans against the step III 56 provided in the bearing hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com