Method for calculating movement of inclusions in VIM smelting process

A technology of smelting process and inclusions, which is applied in the field of calculating the movement of inclusions in the VIM smelting process, can solve the problems that have not been reported, and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

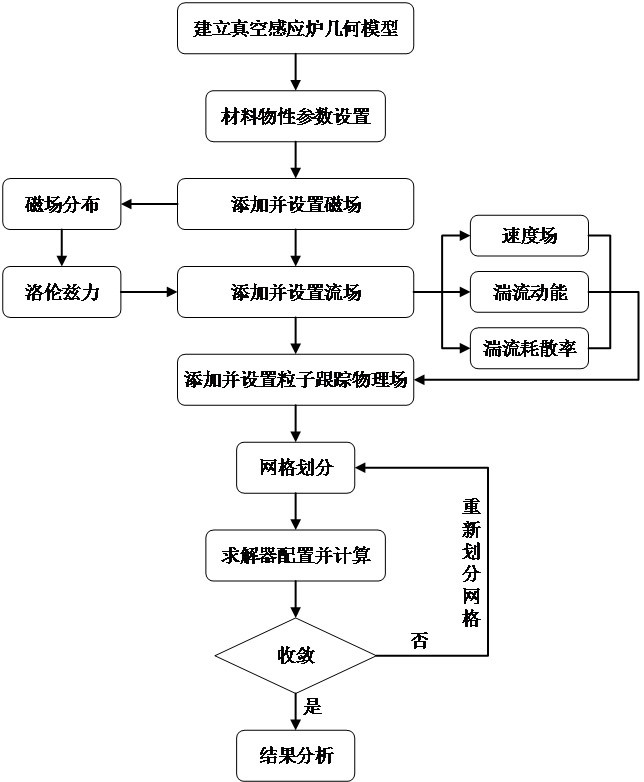

[0108] like figure 1 As shown, this embodiment provides a method for calculating the movement of inclusions in the VIM smelting process based on COMSOL simulation, and the method includes the following steps:

[0109] (1) Establish the geometric model of the vacuum induction furnace.

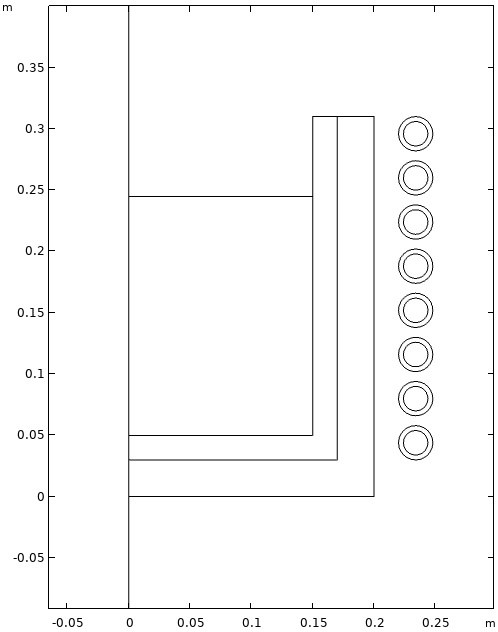

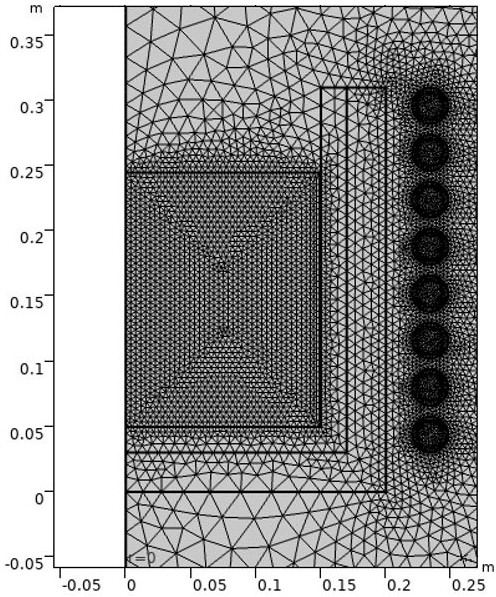

[0110] like figure 2 As shown, the geometric model of the vacuum induction furnace is established, and the geometric dimensions of the model are as follows: the height of the furnace charge is 195mm; the size of the crucible is φ340mm×H280mm, and the wall thickness is 20mm; the size of the insulation material is φ400mm×H310mm, and the wall thickness is 30mm; 28mm, the gap between the coils is 8mm, and the number of coil turns is 8 turns. According to the above parameters, COMSOL was used to draw the geometric model of the vacuum induction furnace, and the outermost layer of the geometric model of the vacuum induction furnace was defined as an infinite element domain, and the coordinate syste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com