Energy-saving conductor and preparation method thereof

A conductor and wire technology, applied in the field of energy-saving conductors and their preparation, can solve the problems of uneven surface, compactness, large material consumption, and large conductor outer diameter of circular non-compressed conductors, so as to reduce the outer diameter of conductor stranding. , improve transmission efficiency, improve the effect of overall quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Next, the present invention is further described in conjunction with the accompanying drawings and specific embodiments:

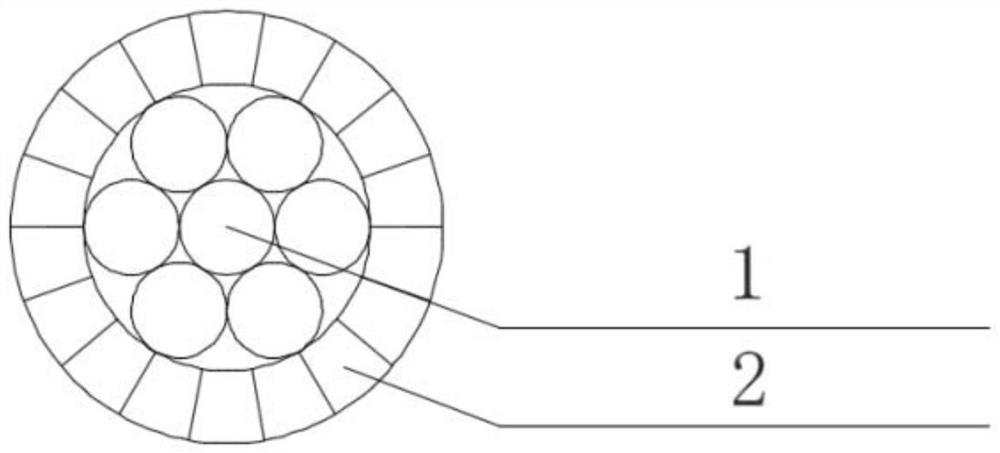

[0024] Append figure 1 As shown, the energy-saving conductor of the present invention includes a circular wire non-tight stranded unit and a shaped wire stranded unit, and the shaped wire stranded unit surrounds the outer side of the circular first non-tight stranded unit.

[0025] Append figure 1 As shown, the circular wire non-tight stranded unit comprises m circular wire 1; M is an integer greater than 1. The circular wire includes a core I and an insulating sheath I that surrounds the outer side of the core I; an insulating sheath I is used to isolate adjacent circular wires.

[0026] Append figure 1 As shown, the shaped wire stranded unit comprises N as-like wires; the shaped wires are surrounded by cylindrical 2, the shaped wires include core II and insulated sheath II around the outside of the core II; insulating sheath II for will be adjacent Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com