Preparation method of steel shell button cell, and steel shell button cell

A button-type battery, steel shell technology, applied in the direction of cylindrical shell battery/battery, secondary battery manufacturing, battery pack components, etc., can solve the problems of poor sealing effect, battery explosion, difficult pressure relief, etc. Use safety, prevent liquid leakage, improve the effect of power storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

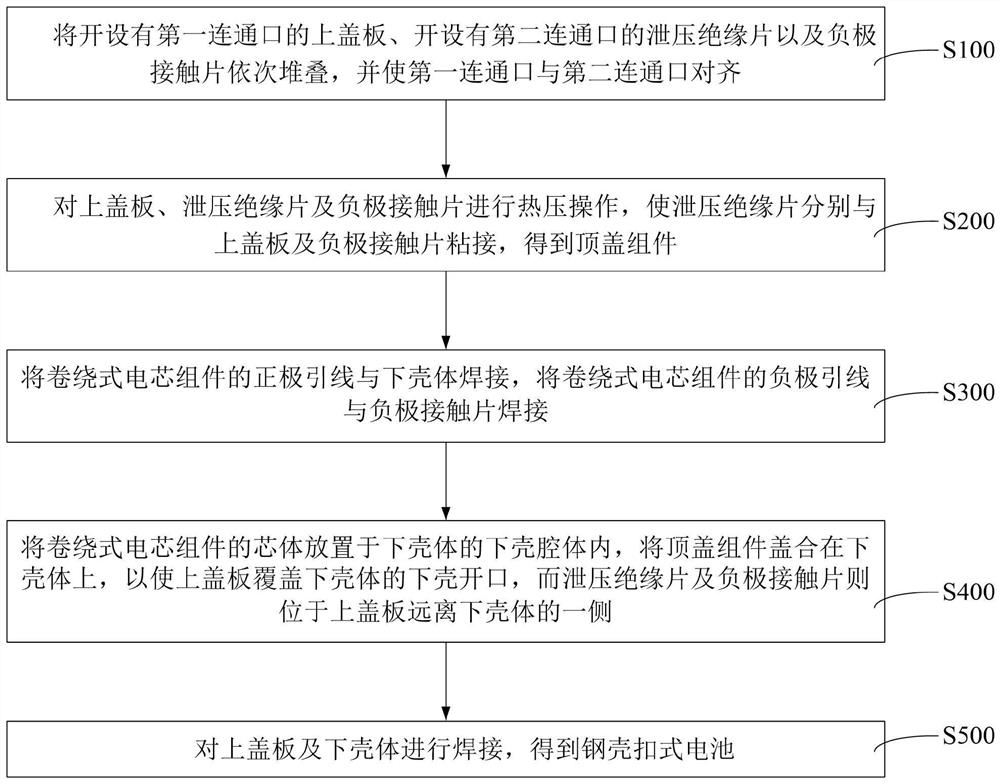

[0038] The preparation method of the steel case button battery of an embodiment comprises the following steps:

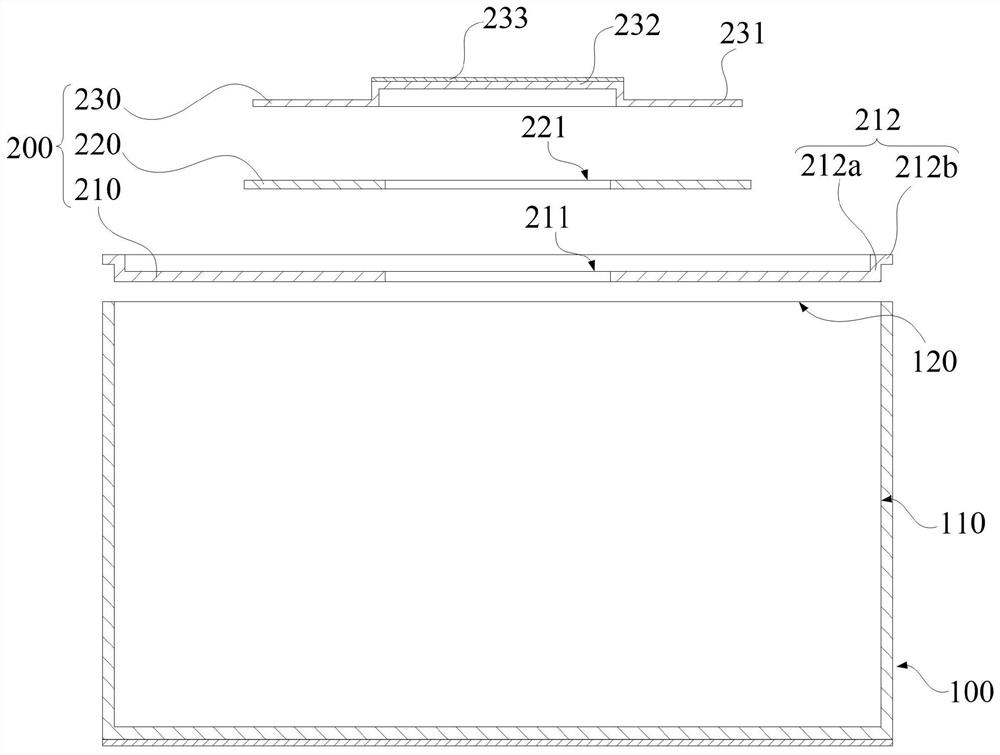

[0039] Stack the upper cover plate with the first communication port, the pressure relief insulating sheet with the second communication port and the negative electrode contact sheet in sequence, and align the first communication port with the second communication port;

[0040] Perform hot pressing operation on the upper cover plate, the pressure relief insulating sheet and the negative electrode contact sheet, so that the pressure relief insulating sheet is respectively bonded to the upper cover plate and the negative electrode contact sheet to obtain a top cover components;

[0041] Welding the positive lead of the wound cell assembly to the lower case, and welding the negative lead of the wound cell assembly to the negative contact piece;

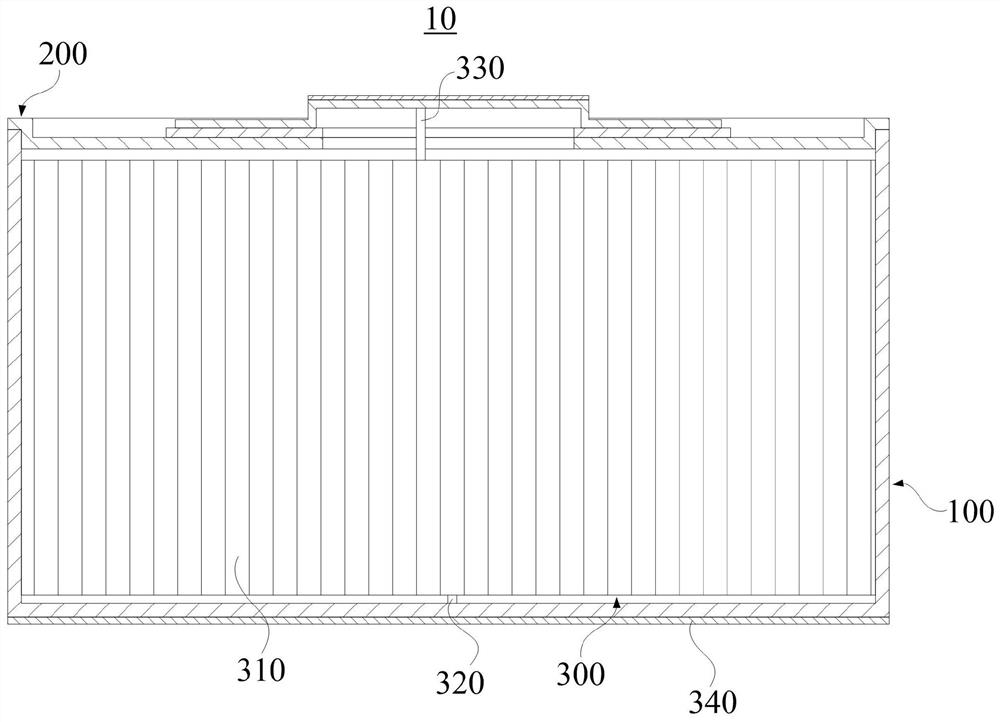

[0042] Place the core body of the wound battery assembly in the lower casing cavity of the lower casing, and cover the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com