Battery cover of pole, power battery and battery module

A technology for power batteries and battery covers, which is applied to battery pack parts, circuits, electrical components, etc., which can solve problems such as small welding space, insufficient overcurrent capacity, and easy arcing, so as to reduce welding difficulty and facilitate welding operations , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

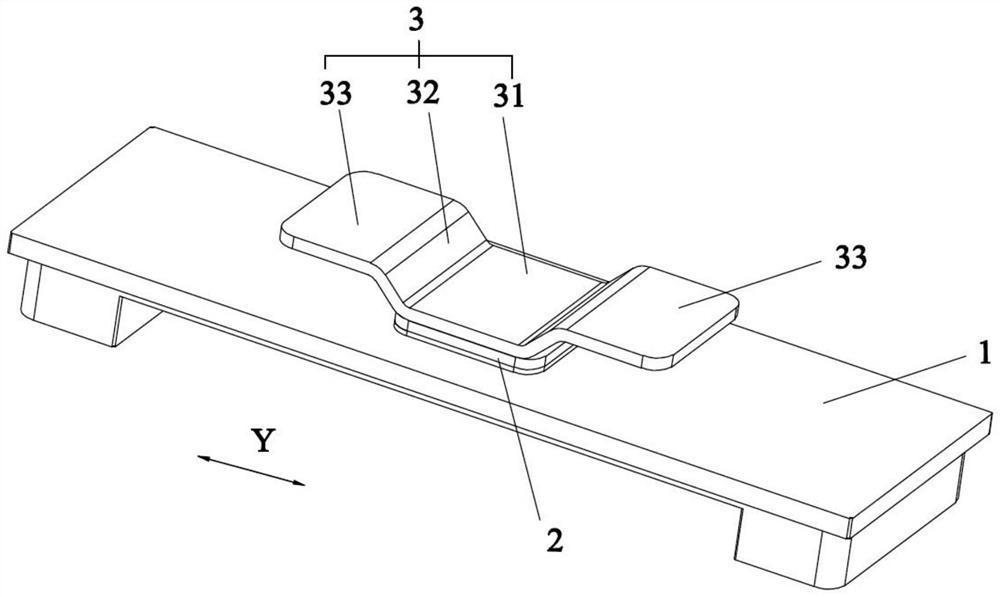

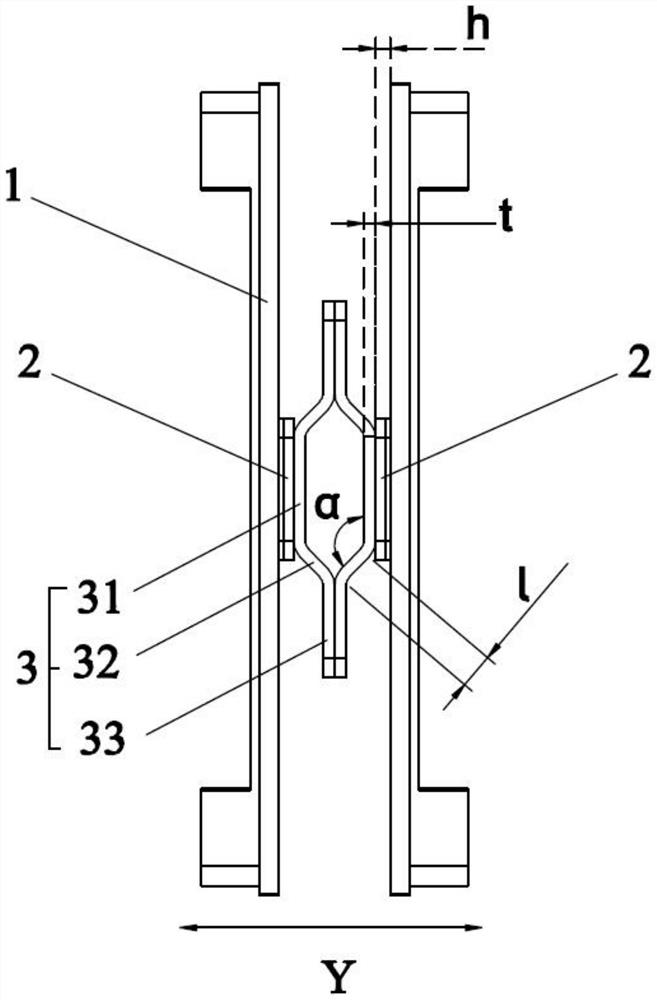

[0040] A pole-column battery cover comprising a cover plate 1; a pole column 2 is disposed in a cover plate 1; a bus member 3 is disposed at the end surface of the pole column 2, the bus member 3 includes an overflow portion 31, a transition portion 32, and a connecting portion. 33. The connecting portion 33 is connected by the transition portion 32 at both ends of the overflow portion 31.

[0041] Due to the mode of direct welding between the electrical cells, when the electrical cell is used in the existing battery module, there is no redundant space without the use of the secondary component of the cell; and the welding space is small, both Not conducive to manual welding, is also not conducive to machine welding, so see figure 1 with figure 2 As shown, the bushing member 3 is disposed at the end surface of the pole column 2, satisfying the amount of overflow capability after the battery and the battery, and converts the welding between the pole column 2 and the pole column 2 ...

Embodiment approach 2

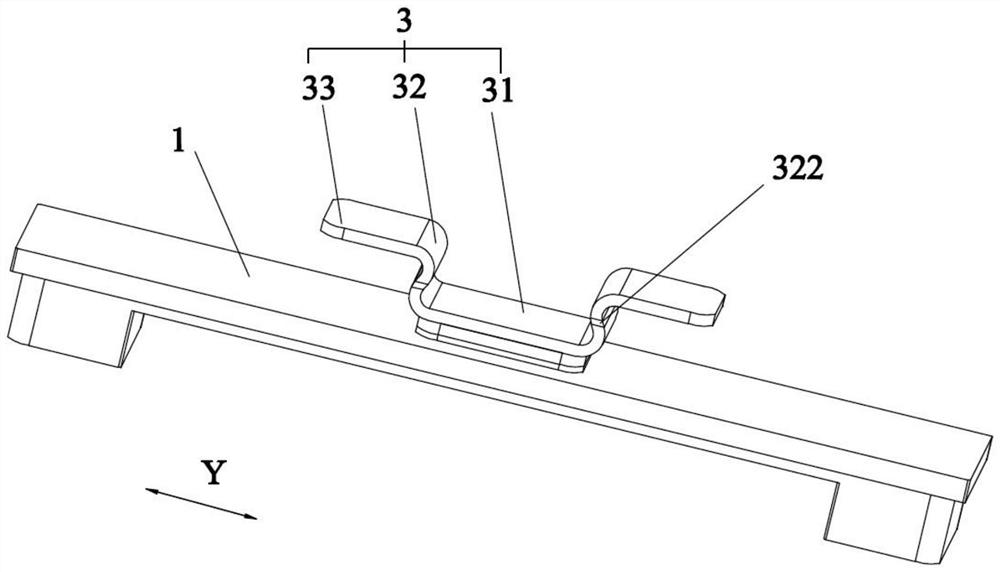

[0048] Unlike the embodiment: the transition portion 32 of the present embodiment includes a plurality of arc 321 sequentially connected. In this embodiment, see image 3 with Figure 4 As shown, the transition portion 32 is composed of arc 321, linear segment 322, and arc 321, but the present invention is not limited, and can be divided into two structures of the third embodiment.

[0049] Other structures are identical to the implementation, and details are not described here.

Embodiment approach 3

[0051] Unlike the second embodiment, see Figure 5 As shown, the arc 321 of the present embodiment is a quarter arc, and the two arc 321 and the linear segment 322 are tangent, and the welding size between the adjacent bushings 3 is W, which satisfies the relationship: W = H + T + M + 2R, where R is the radius of the arc 321, and m is the length of the linear segment 322, and H is the height of the pole column 2, and T is the thickness of the overflow portion 31. The transition portion 32 of the present embodiment includes a circular arc 321, a linear segment 322, and a circular arc 321, and the two arc 321 are tangered with the intermediate linear segment 322, and the arc 321 is a quarter arc. At the time, the length of the line segment 322 is the largest, and the height H of the polar column 2 is equal to the thickness T of the overflow portion 31, and K is the length of the transition portion 32 on the width direction Y, from M = K-2R, That is, K = M + 2R, the welding size betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com