High-yield SMT process for high-quality solder paste printing

A solder paste printing, high yield technology, applied in the direction of printed circuit, printed circuit manufacturing, printed circuit assembly of electrical components, etc., can solve problems such as solder paste position overrun, short circuit, solder point bridging, etc., to avoid balling, Effect of improving activity and uniformity and increasing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

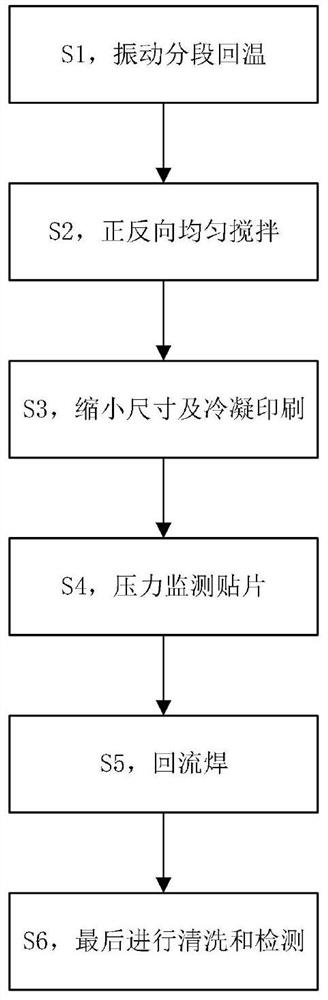

[0046] refer to figure 1 As shown, this embodiment discloses a high-yield SMT process for high-quality solder paste printing, including the following steps:

[0047] S1, return to temperature

[0048] a. Take the solder paste out of the refrigerator and quickly place it on the vibrating plate in the reheating box. The initial temperature in the reheating box is the same as that in the refrigerator;

[0049] b. Raise the temperature in the reheating box to 15°C evenly and slowly, and the heating time is 0.5-1H, while keeping the vibration frequency of the vibrating plate at 200-350Hz, and the amplitude does not exceed 0.1mm;

[0050] c. After the temperature reaches 15°C, keep it warm for 1-1.2 hours, while keeping the vibration frequency of the vibrating plate at 500-1000Hz;

[0051] d. Raise the temperature in the reheating box to 50°C evenly and slowly, and the heating time is 0.2-0.5H, while keeping the vibration frequency of the vibrating plate at 200-350Hz, and the ampl...

Embodiment 2

[0066] This embodiment discloses a high-yield SMT process for high-quality solder paste printing, including the following steps:

[0067] S1, return to temperature

[0068] a. Take the solder paste out of the refrigerator and quickly place it on the vibrating plate in the reheating box. The initial temperature in the reheating box is the same as that in the refrigerator;

[0069] b. Raise the temperature in the reheating box to 15°C evenly and slowly, and the heating time is 0.751H, while keeping the vibration frequency of the vibrating plate at 275Hz, and the amplitude does not exceed 0.1mm;

[0070] c. After the temperature reaches 15°C, keep it warm for 1.1H while keeping the vibration frequency of the vibrating plate at 750Hz;

[0071] d. Raise the temperature in the reheating box to 50°C evenly and slowly, and the heating time is 0.35H, while keeping the vibration frequency of the vibrating plate at 275Hz, and the amplitude does not exceed 0.1mm;

[0072] e. After the t...

Embodiment 3

[0086] This embodiment discloses a high-yield SMT process for high-quality solder paste printing, including the following steps:

[0087] S1, return to temperature

[0088] a. Take the solder paste out of the refrigerator and quickly place it on the vibrating plate in the reheating box. The initial temperature in the reheating box is the same as that in the refrigerator;

[0089] b. Raise the temperature in the reheating box to 15°C evenly and slowly, and the heating time is 0.5~1H, while keeping the vibration frequency of the vibrating plate at 200~350Hz, and the amplitude does not exceed 0.1mm;

[0090] c. After the temperature reaches 15°C, keep it warm for 1-1.2 hours, while keeping the vibration frequency of the vibrating plate at 500-1000Hz;

[0091] d. Raise the temperature in the reheating box to 50°C evenly and slowly, and the heating time is 0.2-0.5H, while keeping the vibration frequency of the vibrating plate at 200-350Hz, and the amplitude does not exceed 0.1mm; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com