Double-gap electromagnetic shielding system, design method thereof and microwave circuit

A technology of electromagnetic shielding and design method, applied in the fields of magnetic field/electric field shielding, shielding materials, electrical components, etc., can solve problems such as uncorrectable, single-gap electromagnetic shielding structure difficult to apply microwave, millimeter wave circuit upgrade and transformation, large structure thickness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

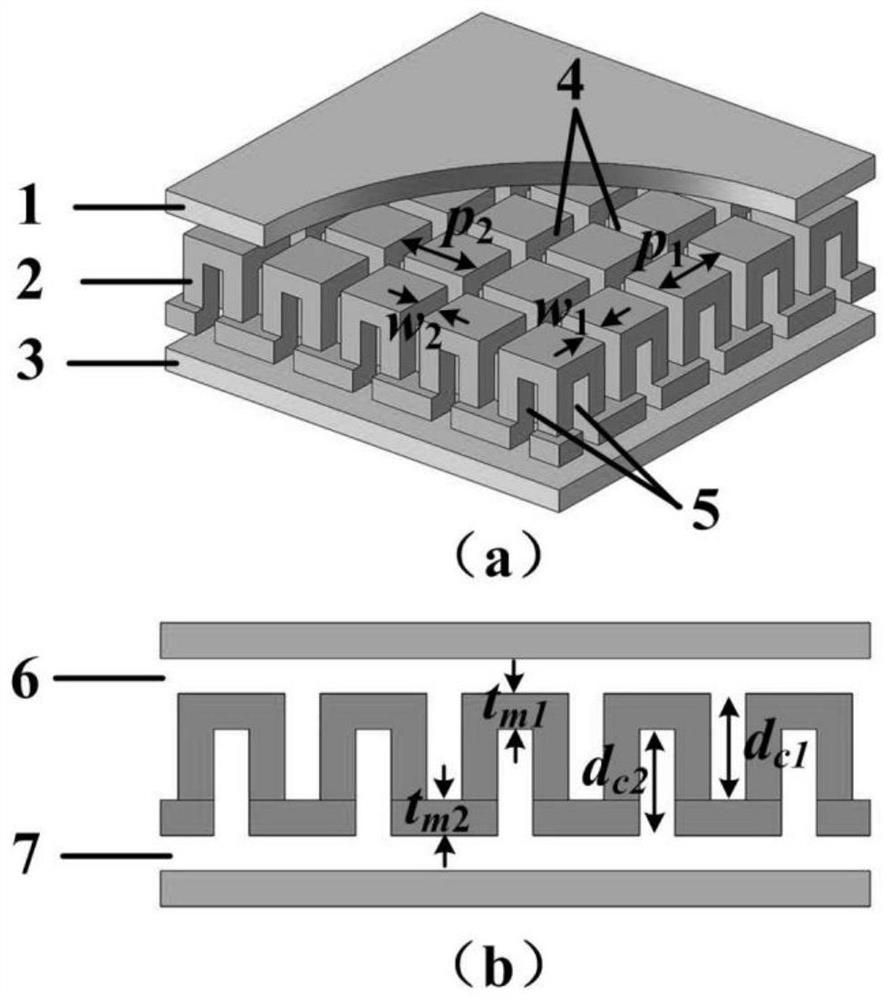

[0085] Such as figure 1 As shown, the double-gap electromagnetic shielding system provided by the embodiment of the present invention at least includes: a first metal plate, a second metal plate, a third metal plate, the first horizontal and vertical rectangular slots on the front of the second metal plate, the second metal plate Second transverse and longitudinal rectangular slots on the back, a first air gap between the first metal plate and the second metal plate, a second air gap between the third metal plate and the second metal plate.

[0086] Such as Figure 4 As shown, the simulated dispersion diagram of the electromagnetic shielding structure, the specific size is: d c1 = d c2 =6mm,p 1 =p 2 = 4.5 mm; w 1 =w 2 = 1.2 mm; h a1 = h a2 =0.1mm; that is, t m1 = t m2 = 1mm.

Embodiment 2

[0088] Such as figure 1 As shown, the double-gap electromagnetic shielding system provided by the embodiment of the present invention at least includes: a first metal plate, a second metal plate, a third metal plate, the first horizontal and vertical rectangular slots on the front of the second metal plate, the second metal plate Second transverse and longitudinal rectangular slots on the back, a first air gap between the first metal plate and the second metal plate, a second air gap between the third metal plate and the second metal plate.

[0089] Such as Figure 5 As shown, the simulated dispersion diagram of the electromagnetic shielding structure, the specific size is: d c1 = d c2 =6mm,p 1 =p 2 = 4.5 mm; w 1 =w 2 = 1.2 mm; h a1 = h a2 = 0mm; that is, t m1 = t m2 = 1mm.

Embodiment 3

[0091] Such as figure 1 As shown, the double-gap electromagnetic shielding system provided by the embodiment of the present invention at least includes: a first metal plate, a second metal plate, a third metal plate, the first horizontal and vertical rectangular slots on the front of the second metal plate, the second metal plate Second transverse and longitudinal rectangular slots on the back, a first air gap between the first metal plate and the second metal plate, a second air gap between the third metal plate and the second metal plate.

[0092] Such as Figure 6 As shown, the simulated dispersion diagram of the electromagnetic shielding structure, the specific size is: d c1 = 6mm, d c2 = 4mm, p 1 =p 2 = 4.5 mm; w 1 =w 2 = 1.2 mm; h a1 = h a2 =0.1mm; that is, t m1 = t m2 = 1mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com