A kind of multiphase microwave dielectric ceramic and preparation method thereof by cold sintering

A microwave dielectric ceramic and microwave dielectric technology are applied in the field of electronic ceramic materials, which can solve the problems of difficult-to-cold sintering technology preparation and the like, and achieve the effects of low dielectric constant and wide application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

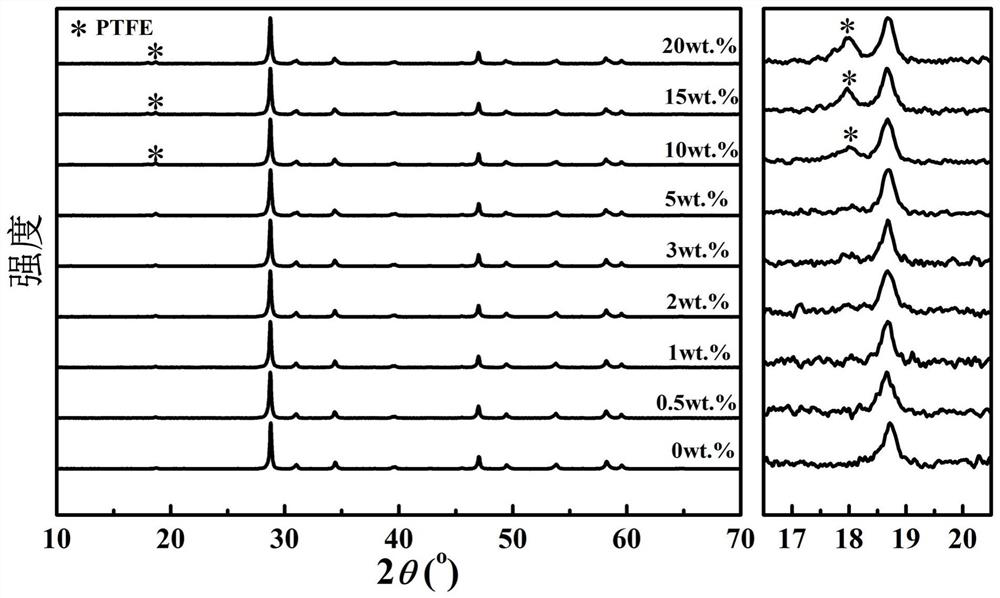

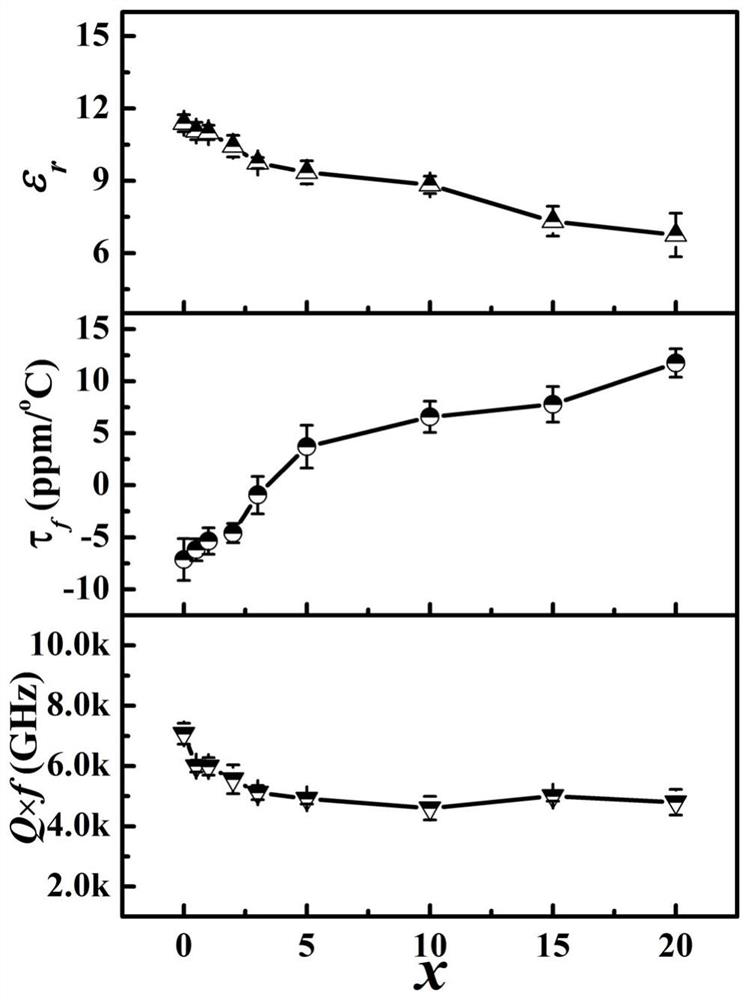

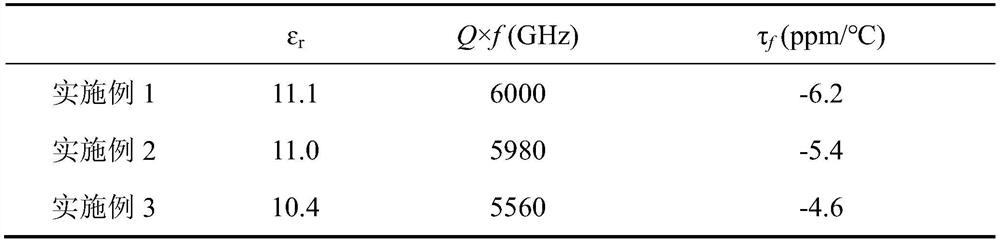

[0018] (1) According to the chemical formula (Ca 0.65 Bi 0.35 )(Mo 0.65 V 0.35 )O 4 -5wt.%Li 2 MoO 4 -0.5wt.% PTFE Weighing CBMVO-LMO and PTFE, using anhydrous ethanol as a medium, ball milled by a planetary ball mill for 10–12 h, and then dried at 80 °C. Weigh an appropriate amount of mixed powder into an agate mortar, add 7wt.% deionized water, grind for 5min, pass the ground powder through an 80-mesh sieve, put it into a hot-pressing mold (diameter 11mm) at a temperature of 150°C and 300MPa The target composite material was obtained by molding under the pressure of 100 °C, keeping the temperature for 1 h, and then drying it at 120 °C for 12 h.

Embodiment 2

[0020] According to the chemical formula (Ca 0.65 Bi 0.35 )(Mo 0.65 V 0.35 )O 4 -5wt.%Li 2 MoO 4 -1 wt.% PTFE Weighing CBMVO-LMO and PTFE, others are the same as in Example 1.

Embodiment 3

[0022] According to the chemical formula (Ca 0.65 Bi 0.35 )(Mo 0.65 V 0.35 )O 4 -5wt.%Li 2 MoO 4 -2wt.% PTFE Weighing CBMVO-LMO and PTFE, the others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality factor | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com