Method for improving uniformity of high-temperature smelted calcium borosilicate glass

A technology of high-temperature smelting and calcium borosilicate, applied in glass rolling, glass forming, glass manufacturing equipment, etc., to achieve the effect of improving product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The method for improving the uniformity of high-temperature smelting calcium borosilicate glass is compared with the traditional process as follows:

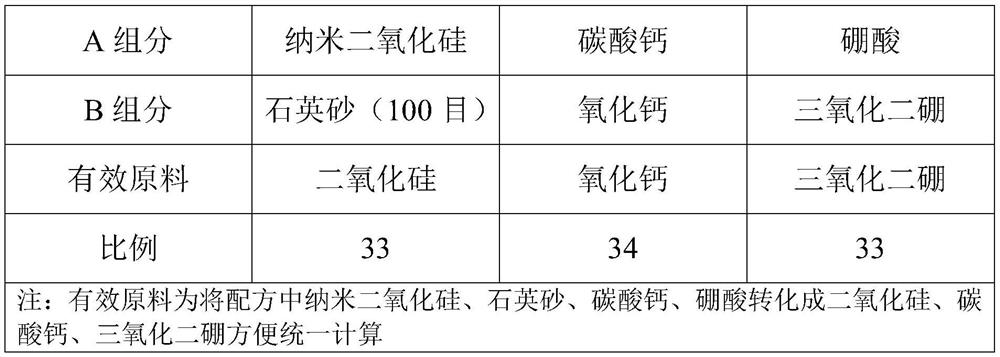

[0026] 1. Selection of glass raw materials: Two sets of glass formulas are designed. The A component uses nano-silica, calcium carbonate, and boric acid as raw materials, and the B component uses 100 mesh quartz sand, calcium oxide, and boron trioxide as raw materials. Calculate the amount of raw materials according to the ratio in Table 1.

[0027] Table 1 Raw material composition list (mass percentage)

[0028]

[0029] 2. Mixing of raw materials: Use a high-speed disperser or a coulter type high-efficiency mixer to fully mix the raw materials.

[0030] 3. High-temperature smelting: use traditional crucible smelting and new stirring smelting methods to smelt A and B glasses respectively, the melting temperature is 1500°C, and the holding time is 3h±0.1h.

[0031] 4. Glass cooling: Use a double-roll cooling mill to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com