Transmission mechanism and mower

A technology of transmission mechanism and lawn mower, which is applied to agricultural machinery and implements, harvesters, chassis of agricultural implements, etc. It can solve the problems that lawn mowers are not widely used, and achieve the advantages of convenient operation, good stability and low center of gravity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

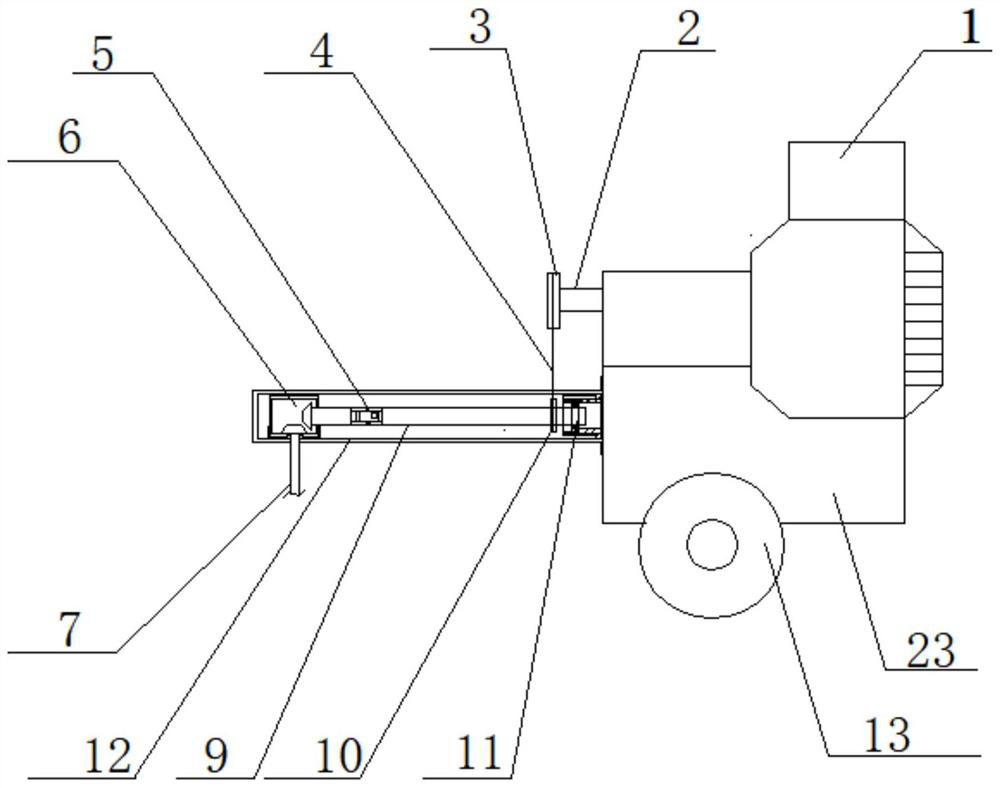

[0087] A transmission mechanism in this embodiment includes a lawnmower working part 7, a first transmission mechanism arranged horizontally, and a height adapter arranged vertically;

[0088] The output shaft 2 of the miniature agricultural machine engine is connected with the height adapter, and the end of the height adapter connected away from the output shaft 2 of the miniature agricultural machine engine is connected with the first transmission mechanism, and the end of the first transmission mechanism is far away from the height adapter. The mower working part 7 is connected; the first transmission mechanism is located below the height adapter.

[0089] The height adapter includes a first transmission wheel 3 and a second transmission wheel 10; the first transmission wheel 3 is connected to the output shaft 2 of the miniature farming machine engine, and the second transmission wheel position 10 is below the first transmission wheel 3 , is connected with the first transmi...

Embodiment 2

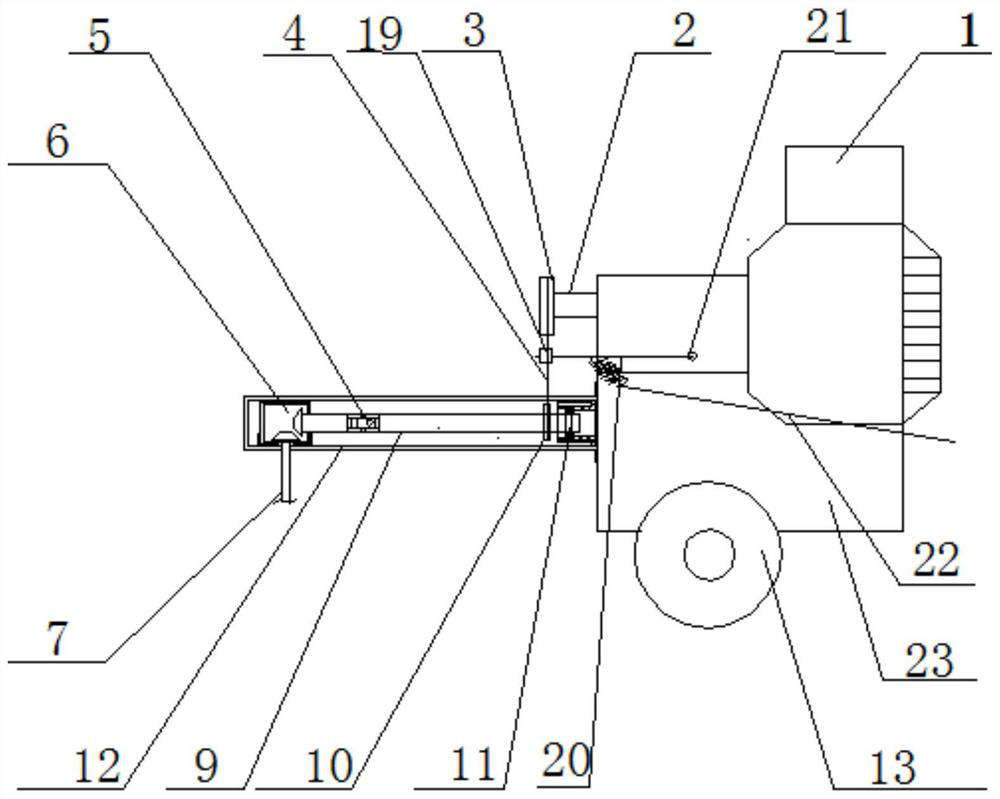

[0100] Where this embodiment is the same as Embodiment 1, no further details are given. The height adapter also includes a pulley clutch structure; the pulley clutch structure includes a belt tensioning device and a belt limiting device; the belt limiting device is arranged on Between the first transmission wheel 3 and the second transmission wheel 10 and on the outside of the transmission belt; the belt limiting device is in contact with the transmission belt 4 in a relaxed state.

[0101] The belt limiter includes two clutch columns 32, and the clutch columns 32 are arranged on the outside of the transmission belt, so that the clutch columns 32 rub against the flat surface of the transmission belt 4, the deceleration process is smooth, and there will be no sudden jam or slippage .

[0102] The belt tensioning device includes: a tensioning pulley 19, a support rod 20, a return spring 31 and a clutch pull wire 22; Under the action of the clutch pull wire 22 and the return spr...

Embodiment 3

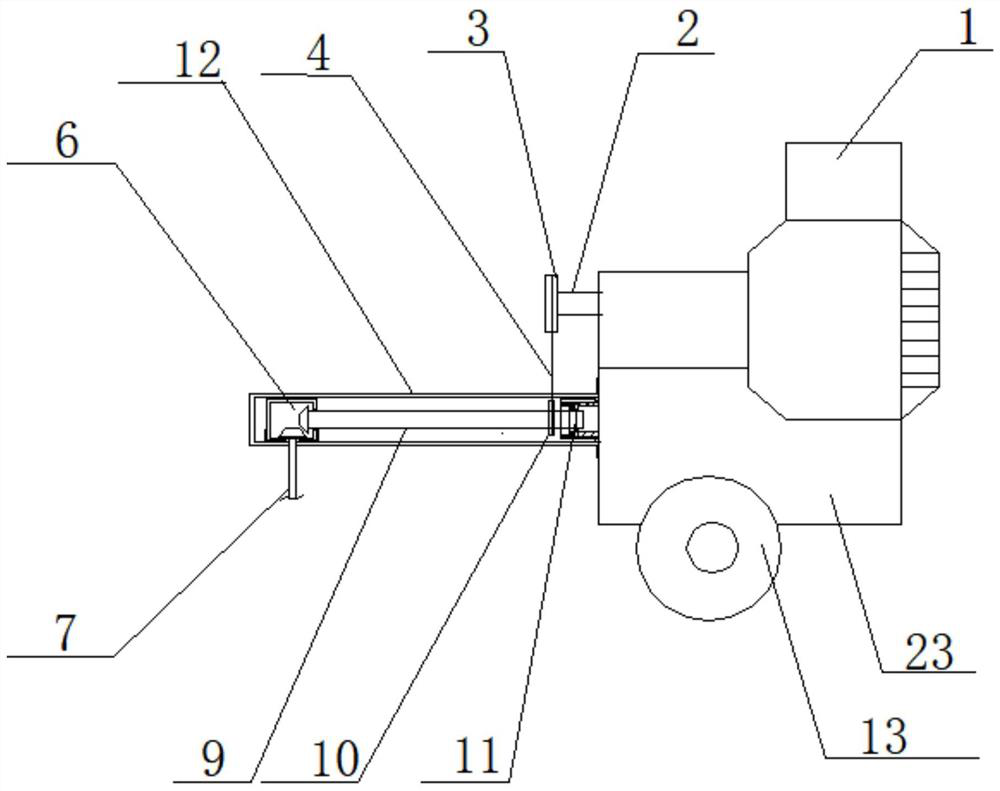

[0104] Where this embodiment is the same as Embodiment 1, no further details are given. This embodiment is a transmission mechanism, which is the same as Embodiment 1;

[0105] In the lawnmower of this embodiment, the direction of the first driven gear is opposite to that of the first driven gear in Embodiment 1.

[0106] The wheel clutch mechanism of this embodiment includes a brake drum 25 and a planetary gear set. The rotating shaft 24 passes through the brake drum 25 and the sun gear 26 of the planetary gear set in turn. The sun gear 26 and the rotating shaft 21 is fixedly connected, the inner gear ring 27 of the planetary gear set is fixedly connected with the brake drum 25, the brake drum 25 is rotationally connected with the wheel transmission shaft 24 through bearings, and the planetary gear carrier of the planetary gear set passes through The bearing is rotatably connected with the wheel drive shaft 24 and fixedly connected with the wheel.

[0107] When braking the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com