Tea frying machine

A tea frying machine and frying pan technology, which is applied in the field of tea frying machines, can solve the problems of unguaranteed tea frying quality and low efficiency, and achieve the effect of ensuring the stir-frying effect, good heating uniformity, and fast heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

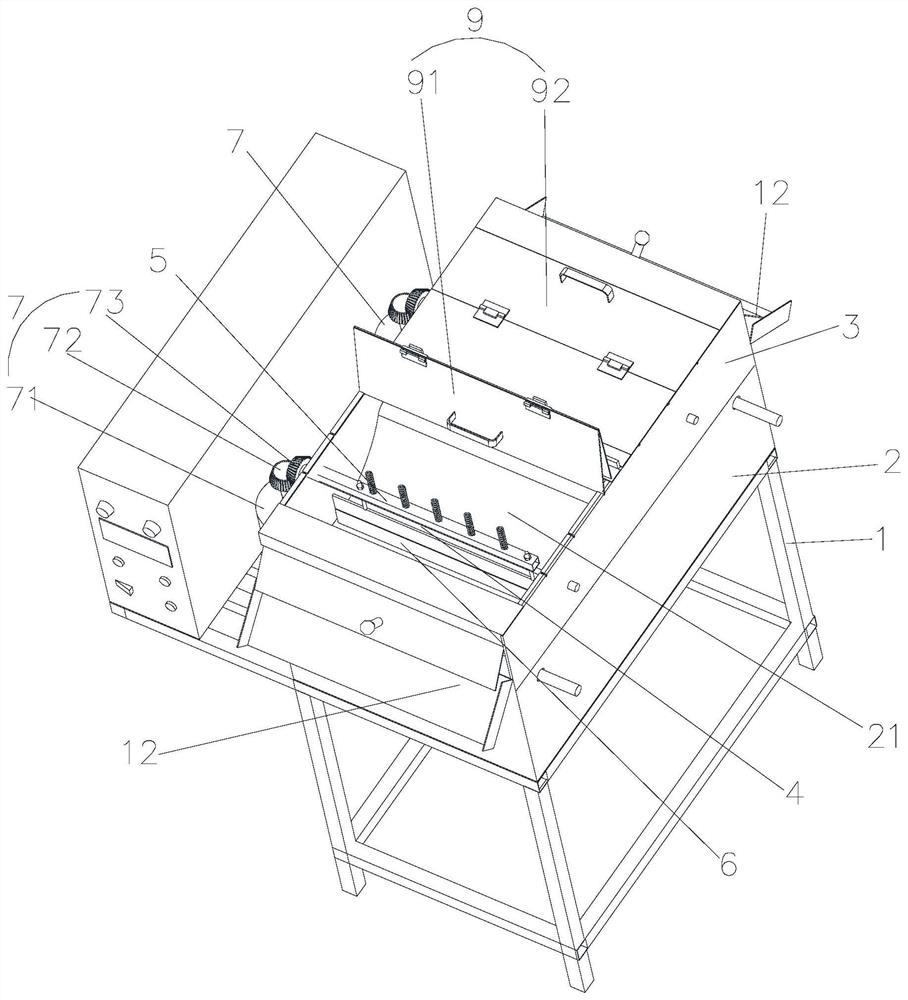

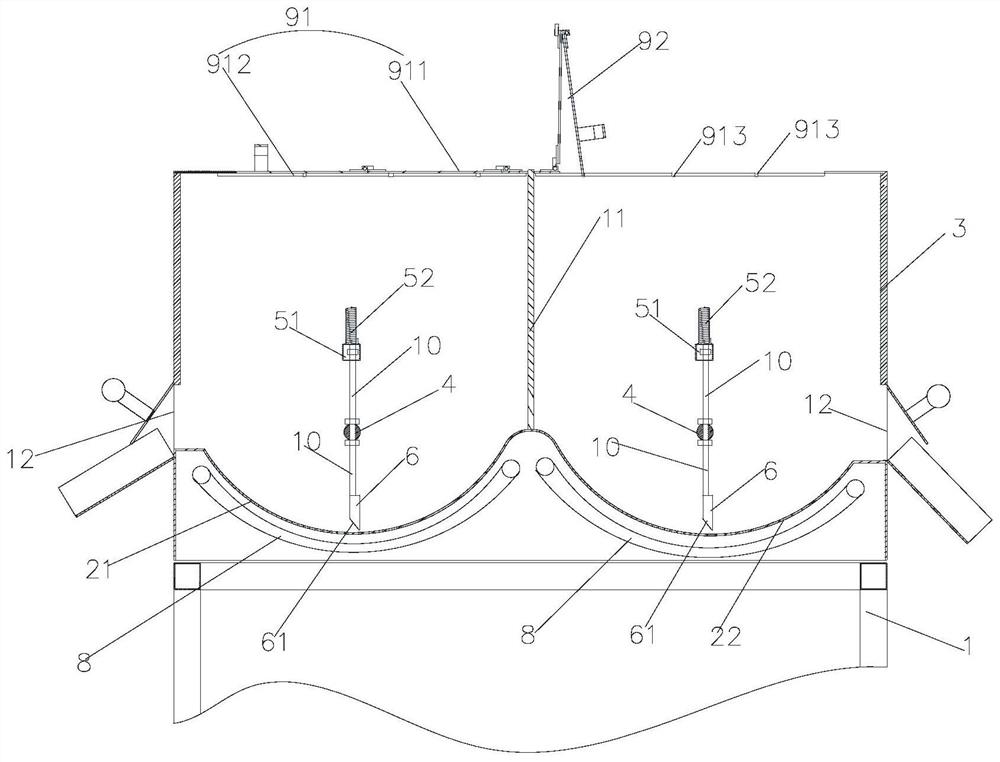

[0019] Examples such as Figures 1 to 3 As shown, a tea frying machine includes a frame 1, a pot body 2 is arranged on the frame 1, a heating device 8 for heating the pot body 2 is arranged under the pot body 2, and a pot body 2 is provided with a The opened side wall 3 is provided with an openable and closable door 12 on the side of the pot body 2 . One end of the side wall 3 is installed on the frame 1 through a hinge, and then buckled and pressed on the top of the pot body 2 . When the pot body 2 needs to be maintained and cleaned, the side wall 3 can be opened to facilitate the pot body 3 maintenance. The tea leaves are fed from the top of the side wall 3, and after being fried in the pot body 2 for a period of time, they are discharged through the door 12.

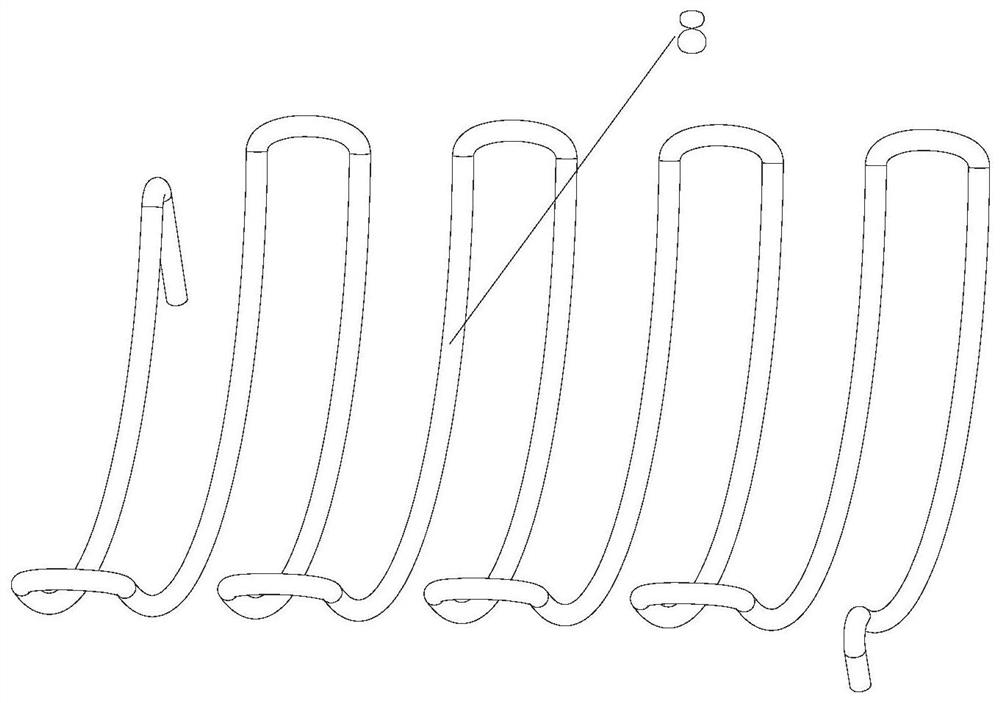

[0020] The pot body 2 includes a left side frying pan 21 and a right side frying pan 22 arranged side by side. The left side frying pan 21 and the right side frying pan 22 are all long groove structures and the cros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arc radius | aaaaa | aaaaa |

| Radian | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com