Method for preparing nanoscale welding flux additive through chemical reaction

A chemical reaction and nano-scale technology, applied in the field of welding additives, can solve the problems such as the inability to prepare Sn nanoparticles, and achieve the effects of convenient operation, reduced process requirements, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

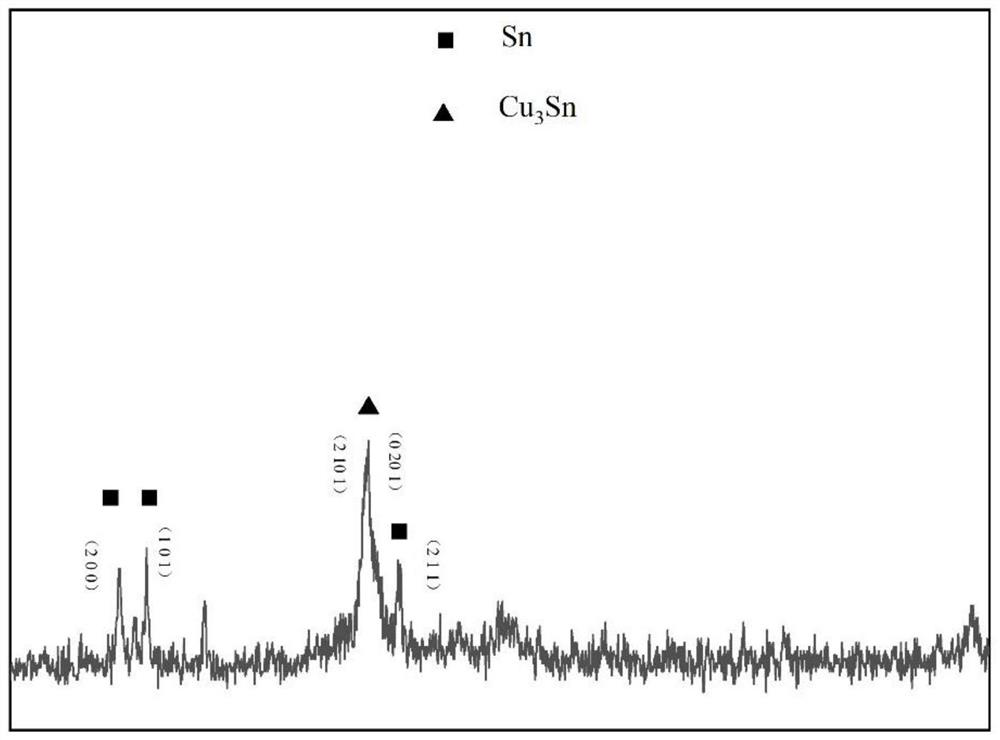

Image

Examples

Embodiment 1

[0020] Embodiment 1: a kind of method for preparing nanoscale solder additive by chemical reaction, concrete steps are as follows:

[0021] (1) CuCl 2 2H 2 O mixed with absolute ethanol to obtain solution A, the SnCl 2 2H 2 O mixed with absolute ethanol to obtain solution B, NaBH 4 Mix with absolute ethanol to obtain solution C; wherein CuCl in solution A 2 2H 2 The concentration of O is 0.150g / mL, the SnCl in solution B 2 2H 2 The concentration of O is 0.125g / mL, NaBH in solution C 4 The concentration of is 0.130g / mL, and the volumes of solution A, solution B and solution C are equal;

[0022] (2) Mix solution A and solution B evenly and raise the temperature to 200°C at a constant speed, then add solution C dropwise to the A-B mixture, shake and react to form a black substance and release a large number of bubbles, shake and react until no bubbles are generated to obtain Seed crystal solution; wherein the drop rate of solution C is 0.05mL / s, and the seed crystals in...

Embodiment 2

[0025] Embodiment 2: a kind of method for preparing nanoscale solder additive by chemical reaction, concrete steps are as follows:

[0026] (1) CuCl 2 2H 2 O mixed with absolute ethanol to obtain solution A, the SnCl 2 2H 2 O mixed with absolute ethanol to obtain solution B, NaBH 4 Mix with absolute ethanol to obtain solution C; wherein CuCl in solution A 2 2H 2 The concentration of O is 0.152g / mL, the SnCl in solution B 2 2H 2 The concentration of O is 0.128g / mL, NaBH in solution C 4 The concentration of is 0.128g / mL, and the volumes of solution A, solution B and solution C are equal;

[0027] (2) Mix solution A and solution B evenly and raise the temperature to 220°C at a constant speed, then add solution C dropwise to the A-B mixture, and shake to form a black substance and release a large number of bubbles, and shake until no bubbles are produced. Seed crystal solution; wherein the drop rate of solution C is 0.07mL / s, and the seed crystals in the seed crystal solu...

Embodiment 3

[0030] Embodiment 3: a kind of method for preparing nanoscale solder additive by chemical reaction, concrete steps are as follows:

[0031] (1) CuCl 2 2H 2 O mixed with absolute ethanol to obtain solution A, the SnCl 2 2H 2 O mixed with absolute ethanol to obtain solution B, NaBH 4 Mix with absolute ethanol to obtain solution C; wherein CuCl in solution A 2 2H 2 The concentration of O is 0.155g / mL, the SnCl in solution B 2 2H 2 The concentration of O is 0.130g / mL, NaBH in solution C 4 The concentration of is 0.135g / mL, and the volumes of solution A, solution B and solution C are equal;

[0032] (2) Mix solution A and solution B evenly and raise the temperature to 180°C at a constant speed, then add solution C dropwise to the A-B mixture, shake and react to form a black substance and release a large number of bubbles, shake and react until no bubbles are generated to obtain Seed crystal solution; wherein the drop rate of solution C is 0.1mL / s, and the seed crystals in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com