Machining drilling machine equipment with high stability

A mechanical processing and stability technology, which is applied in the direction of metal processing equipment, drilling/drilling equipment, boring machine/drilling machine parts, etc., can solve the problem of clamping and fixing parts with different shapes, the height of the table cannot be adjusted, and the fixing mechanism Complicated structure and other problems, to achieve the effect of firm fixation, controllable drilling depth and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

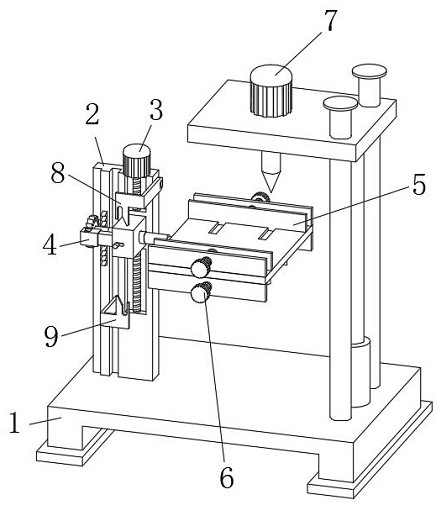

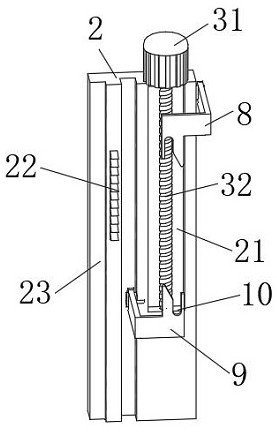

[0034] A high stability machining drilling equipment, such as Figure 1-2As shown, including a base 1, a support frame 2 is fixedly installed on the left side of the upper end of the base 1, and a drive mechanism 3 is inserted through the upper end of the support frame 2, and a turning mechanism 4 is inserted through and connected to the left end of the driving mechanism 3, and the turning mechanism 4 is movably connected with the drive mechanism 3, the upper end, front and rear sides on the right side of the turning mechanism 4 are connected with an upper limit mechanism 5 by common threads, and the upper end, front and rear sides on the right side of the turning mechanism 4 are connected by a lower limit mechanism 6, and the base 1 The right side of the upper end of the upper end is fixedly connected with a drilling mechanism 7, and the drilling mechanism 7 is located above the upper limit mechanism 5 and the lower limit mechanism 6; a chute 21 is opened on the right side of ...

Embodiment 2

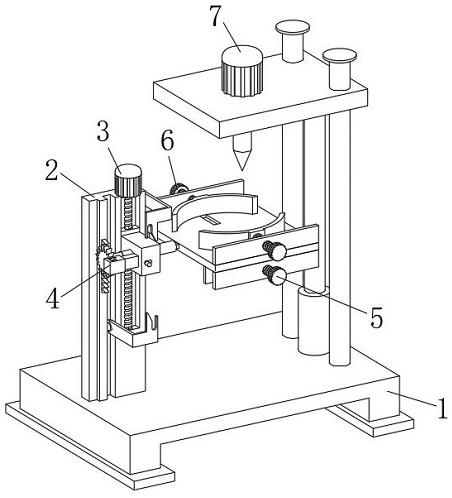

[0037] On the basis of Example 1, as Figure 3-5 As shown, a high-stability mechanical processing drilling machine equipment includes a base 1, a support frame 2 is fixedly installed on the left side of the upper end of the base 1, and a drive mechanism 3 is interspersed and connected to the upper end of the support frame 2. The left end of the drive mechanism 3 An overturning mechanism 4 is interspersed and connected, and the overturning mechanism 4 is movably connected with the driving mechanism 3, and an upper limit mechanism 5 is threaded together on the front and rear sides of the upper end on the right side of the overturning mechanism 4, and the front and rear sides on the right side of the overturning mechanism 4 are connected together. A lower limit mechanism 6 is threadedly connected, and a drilling mechanism 7 is fixedly connected to the upper right side of the base 1, and the drilling mechanism 7 is positioned above the upper limit mechanism 5 and the lower limit me...

Embodiment 3

[0040] On the basis of Example 1, as Figure 6-8 As shown, a high-stability mechanical processing drilling machine equipment includes a base 1, a support frame 2 is fixedly installed on the left side of the upper end of the base 1, and a drive mechanism 3 is interspersed and connected to the upper end of the support frame 2. The left end of the drive mechanism 3 An overturning mechanism 4 is interspersed and connected, and the overturning mechanism 4 is movably connected with the driving mechanism 3, and an upper limit mechanism 5 is threaded together on the front and rear sides of the upper end on the right side of the overturning mechanism 4, and the front and rear sides on the right side of the overturning mechanism 4 are connected together. A lower limit mechanism 6 is threadedly connected, and a drilling mechanism 7 is fixedly connected to the upper right side of the base 1, and the drilling mechanism 7 is positioned above the upper limit mechanism 5 and the lower limit me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com