Real wood ornament injection molding and polyurethane adding one-step molding pouring mold

A technology of polyurethane casting and molding, which is applied in household appliances, household components, and other household appliances. It can solve problems such as complicated steps, low production efficiency, and substandard finished product quality, and achieve simple steps, high production efficiency, and save processing time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

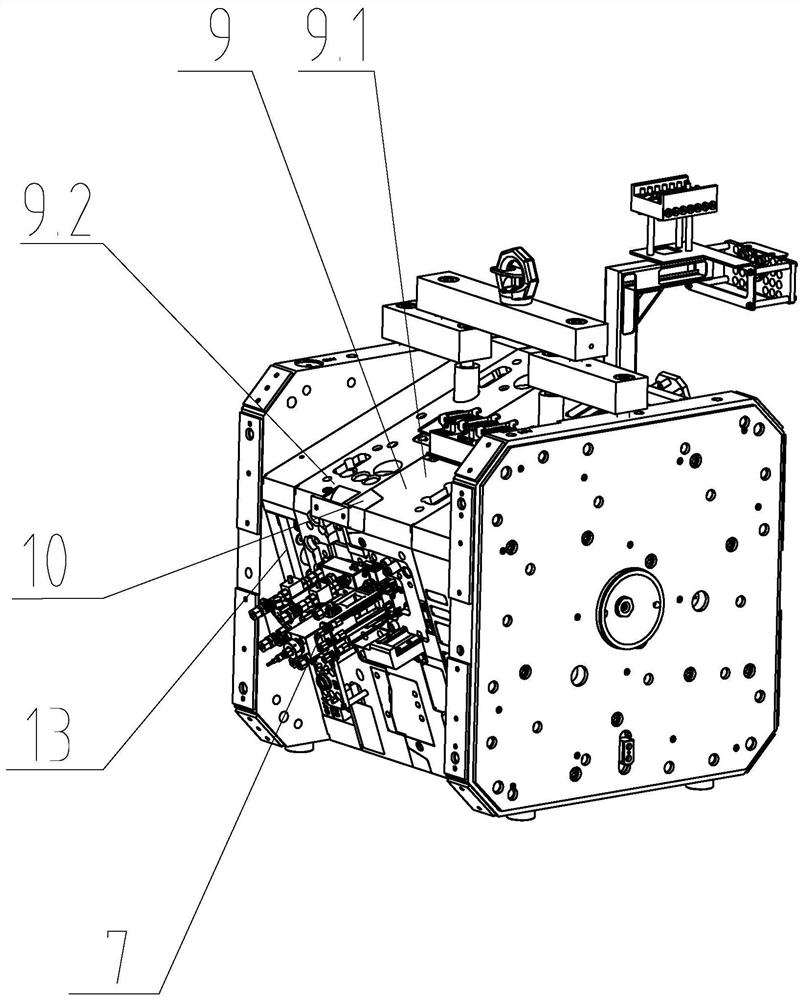

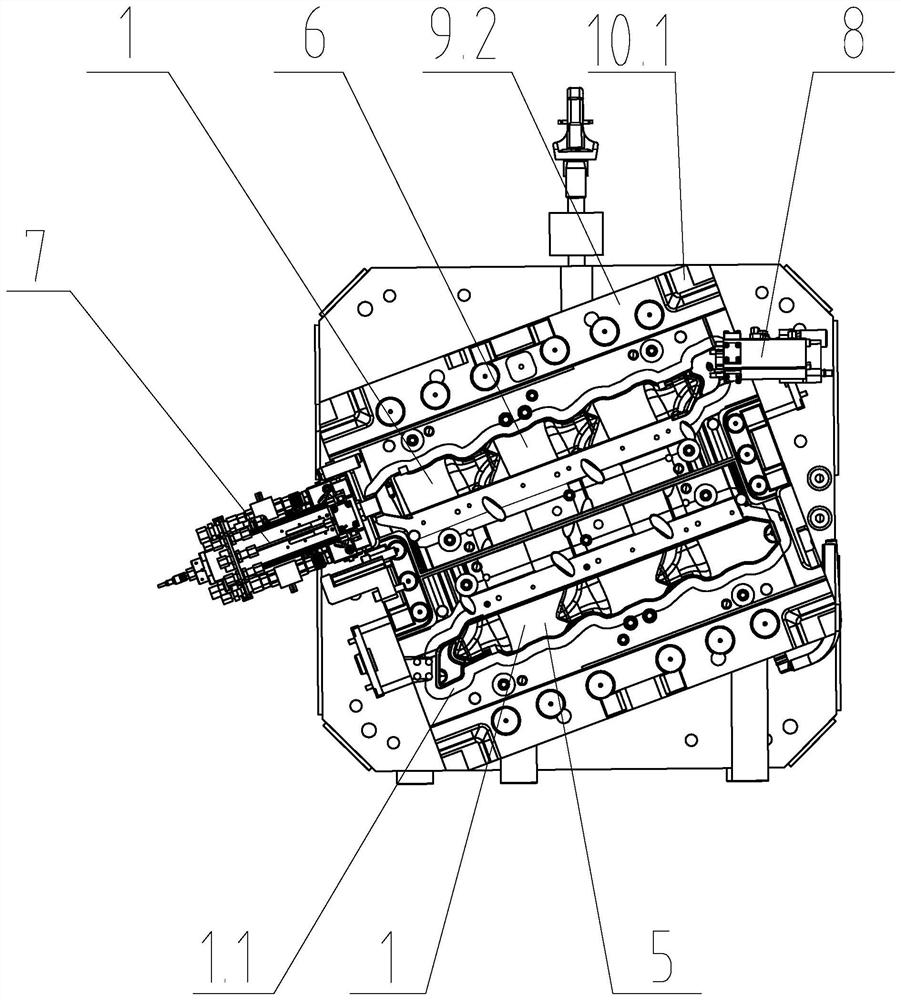

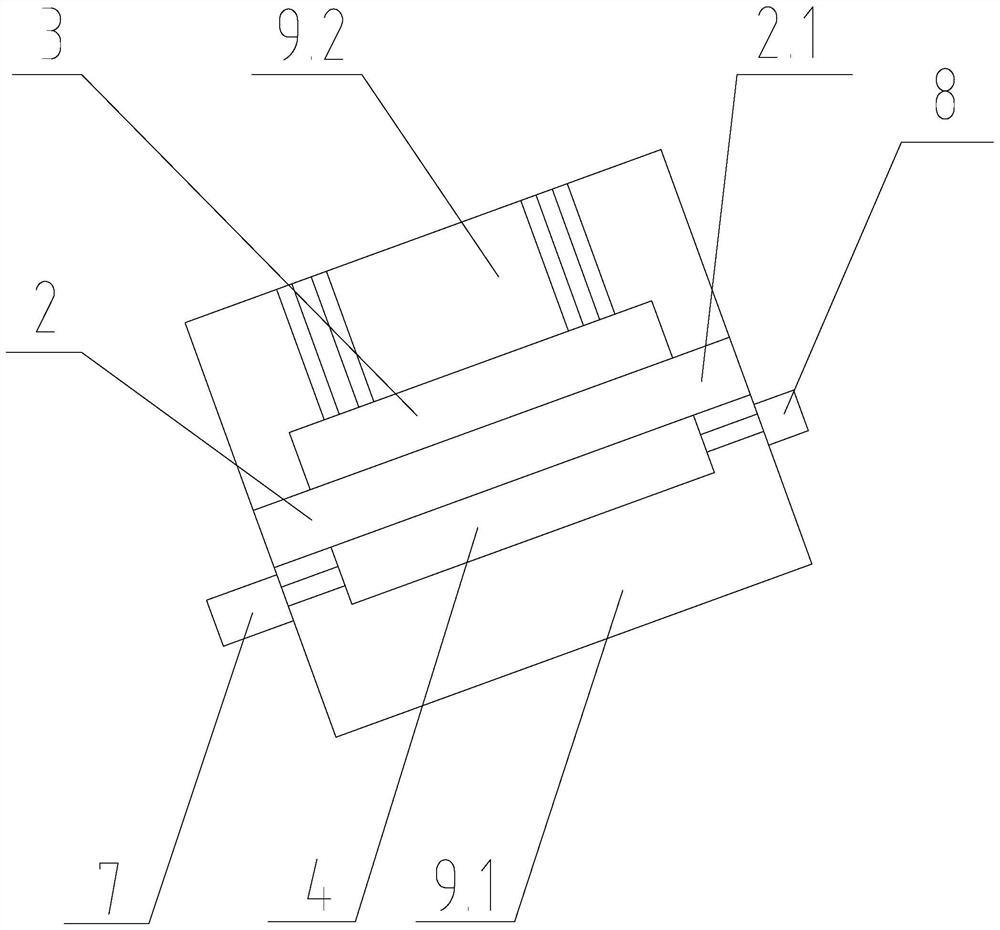

[0025] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0026] Such as Figure 1-3 As shown in the figure, a one-step mold for injection molding of real wood decorative parts and adding polyurethane includes a body, which is rotatably connected around a central axis, and two mold cavities 1 are arranged in the body, and the two mold cavities 1 In the same way, one mold cavity 1 coincides with the other mold cavity 1 after rotating 180 degrees around the central axis, and a veneer layer 2 is fixed inside the cavity 1, and one side of the veneer layer 2 is used for injection molding of plastic 3 molding, the other side of the veneer layer 2 is used for pouring molding of the polyurethane 4, and the injection molding structure of the plastic 3 is a commonly used injection molding structure. Taking the veneer layer 2 as a benchmark, the veneer layer 2 is provided with fixing ribs 2.1 in the circumferential direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com