Carriage for dumper or self-dumping semitrailer

A technology for semi-trailers and dump trucks, which is applied in the direction of vehicles used for freight, arrangement of loading and unloading vehicles, vehicles with inclined bearing motion, etc. problems, to achieve the effect of improving the overall structural strength, improving the anti-swelling ability, and reducing the rupture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

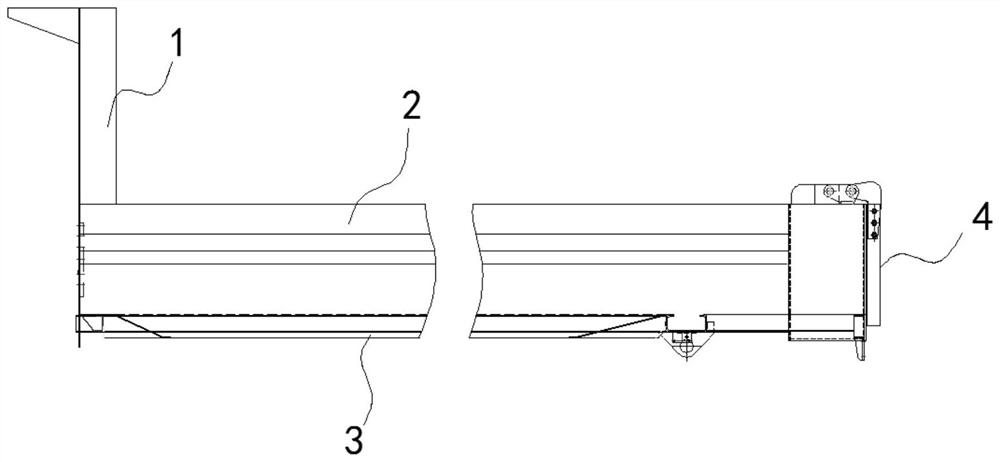

[0059] Such as Figure 1~6 As shown, a compartment for a dump truck or a dump semi-trailer, including a bottom plate 3, a side plate 2, a front plate 1 and a rear plate 4, wherein:

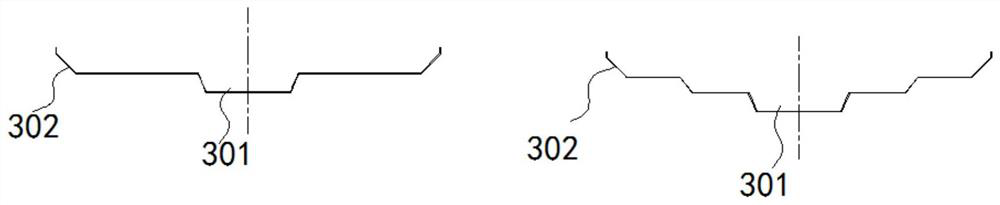

[0060] Specific as figure 2 As shown, the base plate 3 is provided with a sinking portion 301, the sinking portion 301 is located on the median line of the base plate 3, and extends along the length direction of the base plate 3;

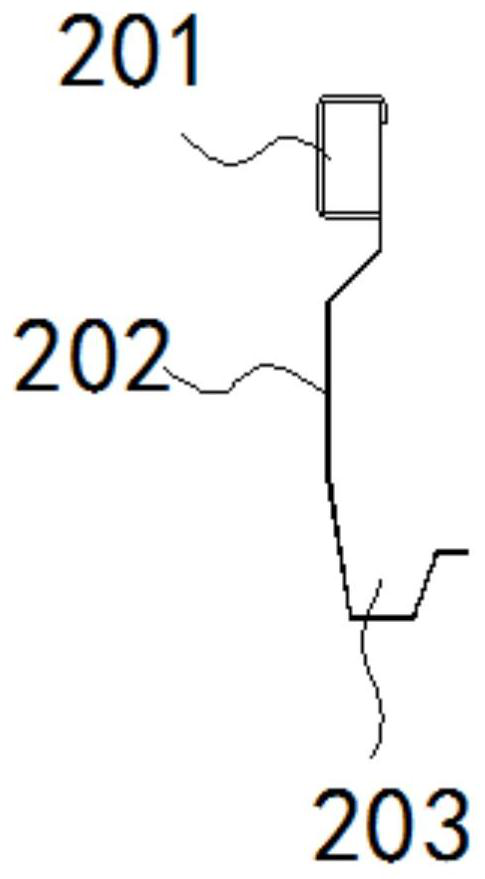

[0061] Specific as image 3 As shown, the lower side of the side plate 2 is provided with a hooked portion 203, after the bottom plate 3 and the side plate 2 are welded, the hooked portion 203 is closed by the bottom plate 3 to form a hollow beam 6 to strengthen and protect the welded part.

[0062] In this embodiment, by designing the sinking part 301, the loaded material can automatically go to the middle, so as to achieve the purpose of automatically centering and lowering the center of gravity; The beam 6 improves the overall structural strength of the compartme...

Embodiment 2

[0064] On the basis of Example 1, such as figure 2 As shown in the right figure of , the sinking part 301 has a multi-level sinking structure, the sinking structure in the middle has the largest depth, and the sinking structures on both sides climb up in a ladder shape, and the sinking structure is about the midline of the bottom plate. symmetry.

[0065] The multi-stage sinking structure in this embodiment can improve the structural strength of the bottom plate 3 on the one hand, and facilitate the collection and flow of materials on the other hand.

[0066] Furthermore, in another embodiment, the two sides of the bottom plate 3 are provided with outward and upward oblique portions 302, the oblique portions 302 correspond to the hooked portions 203 of the side plates 2, and together constitute the Hollow beam6.

[0067] In this embodiment, the obliquely bent portion 302 is convenient for combined welding with the side plate 2 , and also makes the formed hollow beam 6 have ...

Embodiment 3

[0071] On the basis of Example 2, such as Figure 6 As shown, the inside of the hollow beam 6 forms a sliding channel;

[0072] The longitudinal beam 6 and the bottom plate 3 also form a sliding channel after being welded and fixed;

[0073] The vibrating unit 8 is movably arranged in the sliding channel, and the vibrating unit 8 generates vibration to vibrate the materials on the bottom plate 3 .

[0074] This embodiment makes full use of the internal structural space of the hollow beam and the longitudinal beam. The vibration unit slides freely in the sliding channel formed in the internal structural space. The material in the sinking part and the material in the connection between the side plate and the bottom plate are shaken off. On the one hand, this design can make full use of the structural space, avoid the vibration unit being placed outside the carriage and be easily damaged by collision, and avoid affecting the loading operation of the carriage; Avoid unnecessary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com