A kind of preparation method of hard cotton

A technology of hard cotton and cotton layer, which is applied in the cutting of textile materials, textile and paper making, fiber processing, etc. The effect of improving efficiency and improving the sufficiency of heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

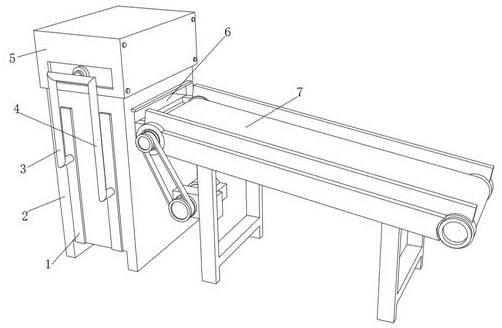

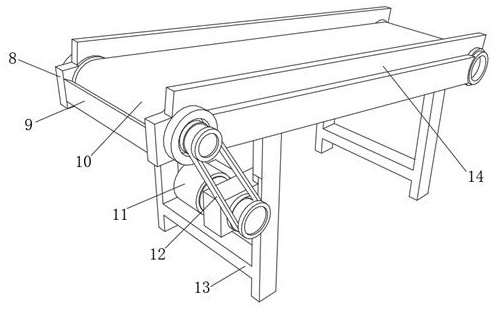

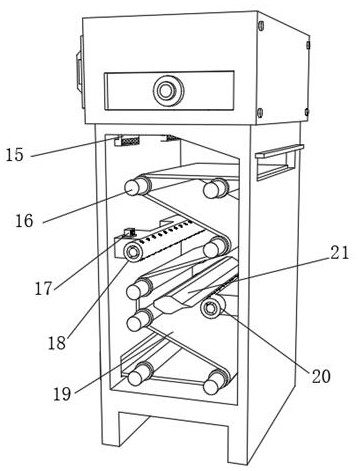

Method used

Image

Examples

Embodiment 1

[0036] A preparation method of hard cotton, comprising the following steps:

[0037] S1: Mix the fiber cotton according to different proportions, weigh the weight and pour it into the mixer for rotation and stirring, so that the fiber cotton is evenly stirred;

[0038] S2: Immediately afterwards, evenly spread the fibers of the agitated group and send them to the licker-in roller device for sequential opening, and the fiber group is sent to the secondary opening device by the fan after strong opening. At this time, After the second opening, the fiber cluster is sent to the cotton mixing box by the fan, and mixed by the vibration of the hopper;

[0039] S3: Then, comb the cotton to a uniform thickness, and transfer the evenly distributed cotton layer to the upper screen, and spread it into a web by the shaking screen;

[0040] S4: Put the uniform cotton layer into the oven, and set the heating temperature to 110-175°C, and the heating time to 35-60s, the low melting point fibers...

Embodiment 2

[0044] A preparation method of hard cotton, comprising the following steps:

[0045] S1: Mix the fiber cotton with a ratio of 1:2:1, and weigh it out and pour it into the mixer for rotation and stirring, so that the fiber cotton is evenly stirred;

[0046] S2: Immediately afterwards, evenly spread the fibers of the agitated group and send them to the licker-in roller device for sequential opening, and the fiber group is sent to the secondary opening device by the fan after strong opening. At this time, After the second opening, the fiber cluster is sent to the cotton mixing box by the fan, and mixed by the vibration of the hopper;

[0047] S3: Then, comb the cotton to a uniform thickness, and transfer the evenly distributed cotton layer to the upper screen, and spread it into a web by the shaking screen;

[0048] S4: Put the uniform cotton layer into the oven, and set the heating temperature to 150°C, and the heating time to 35-60s, the low melting point fibers will entangle ...

Embodiment 3

[0052] A preparation method of hard cotton, comprising the following steps:

[0053] S1: Mix the fiber cotton with a ratio of 1:2:1, and weigh it out and pour it into the mixer for rotation and stirring, so that the fiber cotton is evenly stirred;

[0054] S2: Immediately afterwards, evenly spread the fibers of the agitated group and send them to the licker-in roller device for sequential opening, and the fiber group is sent to the secondary opening device by the fan after strong opening. At this time, After the second opening, the fiber cluster is sent to the cotton mixing box by the fan, and mixed by the vibration of the hopper;

[0055] S3: Then, comb the cotton to a uniform thickness, and transfer the evenly distributed cotton layer to the upper screen, and spread it into a web by the shaking screen;

[0056] S4: Send the uniform cotton layer into the oven, and set the heating temperature to 150°C and the heating time to 50s, the low-melting point fibers will entangle var...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com