Anchors for integrated pipe piles

An integrated anchor tensioner technology, which is applied to sheet pile walls, buildings, and foundation structure engineering, can solve problems such as difficulty in ensuring the quality of concrete pouring, high construction difficulty, and slow construction speed, so as to save concrete and ensure pile formation The effect of quality, ease of transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

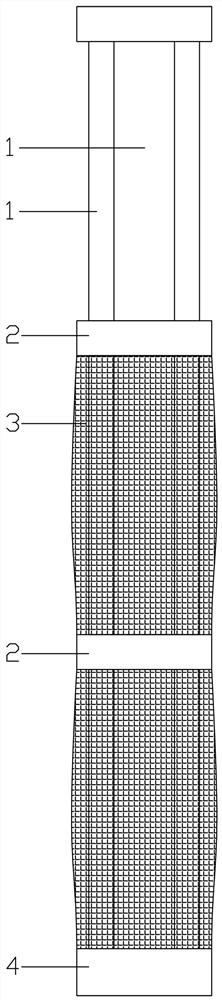

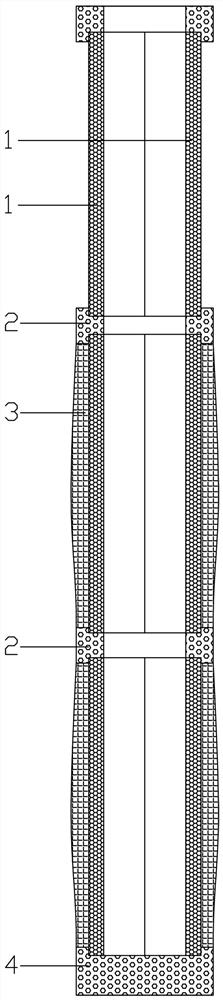

[0056] The first step: At the predetermined position, use mechanical equipment to form holes in the soil of the site to form pile holes;

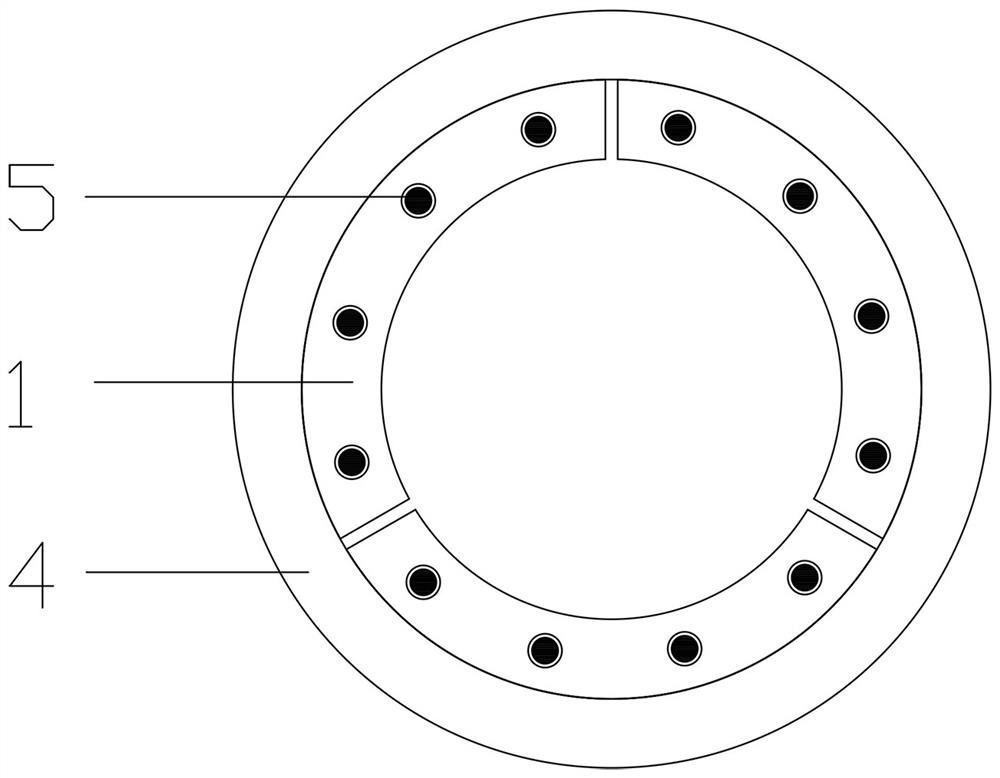

[0057] Step 2: Assemble the end pressure seat, pile slab and anti-slip restraint ring to form the first section (lowest section) of the annular pile body, and put it into the pile hole;

[0058] Step 3: Adjust the vertical position of the first ring-shaped pile body, and then assemble the pile slab and anti-slip restraint ring to form the second ring-shaped pile body;

[0059] Step 4: Adjust the vertical position of the assembled ring-shaped pile body, and then assemble the pile slab and anti-slip restraint ring to form the third section of ring-shaped pile body, repeating successively until the top elevation of the complete pile body is located on the natural ground When the above position is suitable, install the anchor tensioner, stretch and lock each prefabricated component of the pipe pile to form a whole, and then place the complete r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com